Gas engine intake mixing cavity

A gas engine, mixing chamber technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as poor uniformity of each cylinder, excessive emissions, and differences in volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

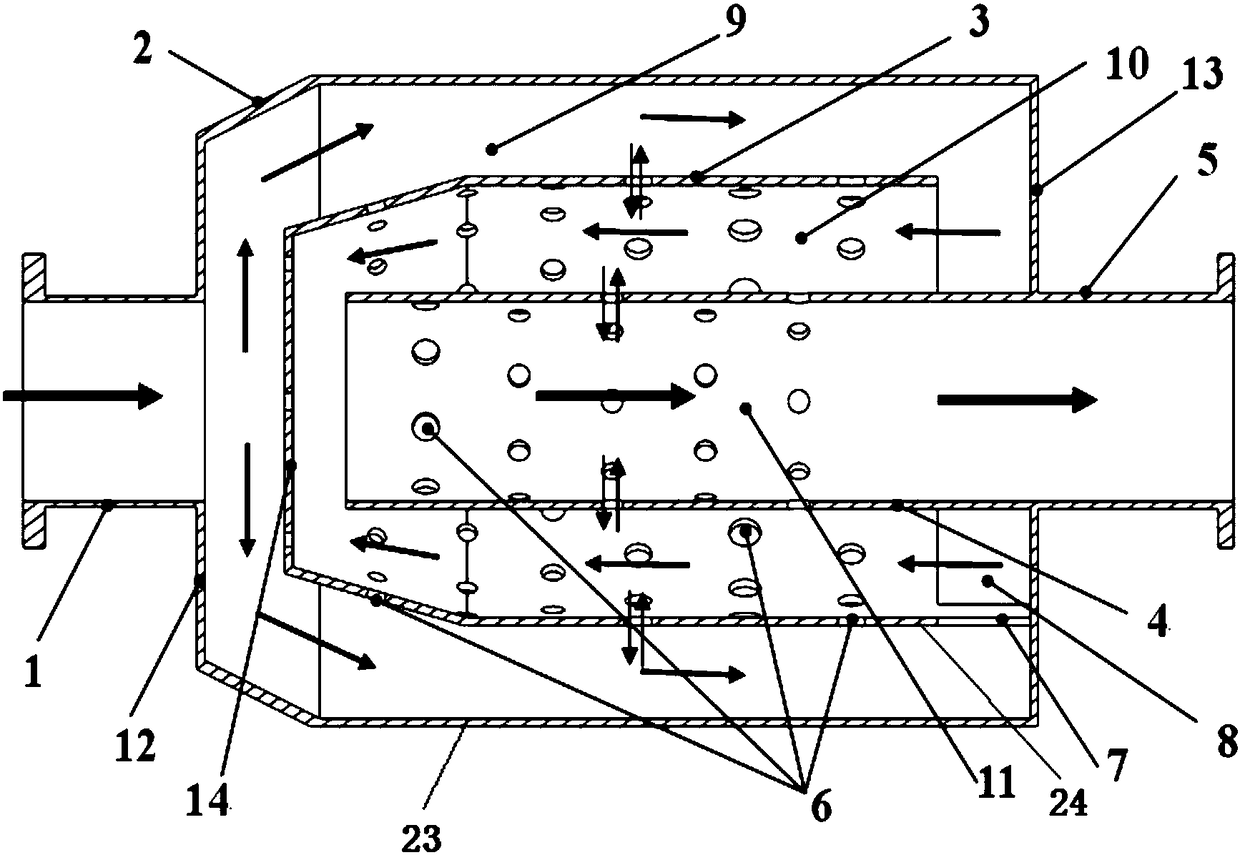

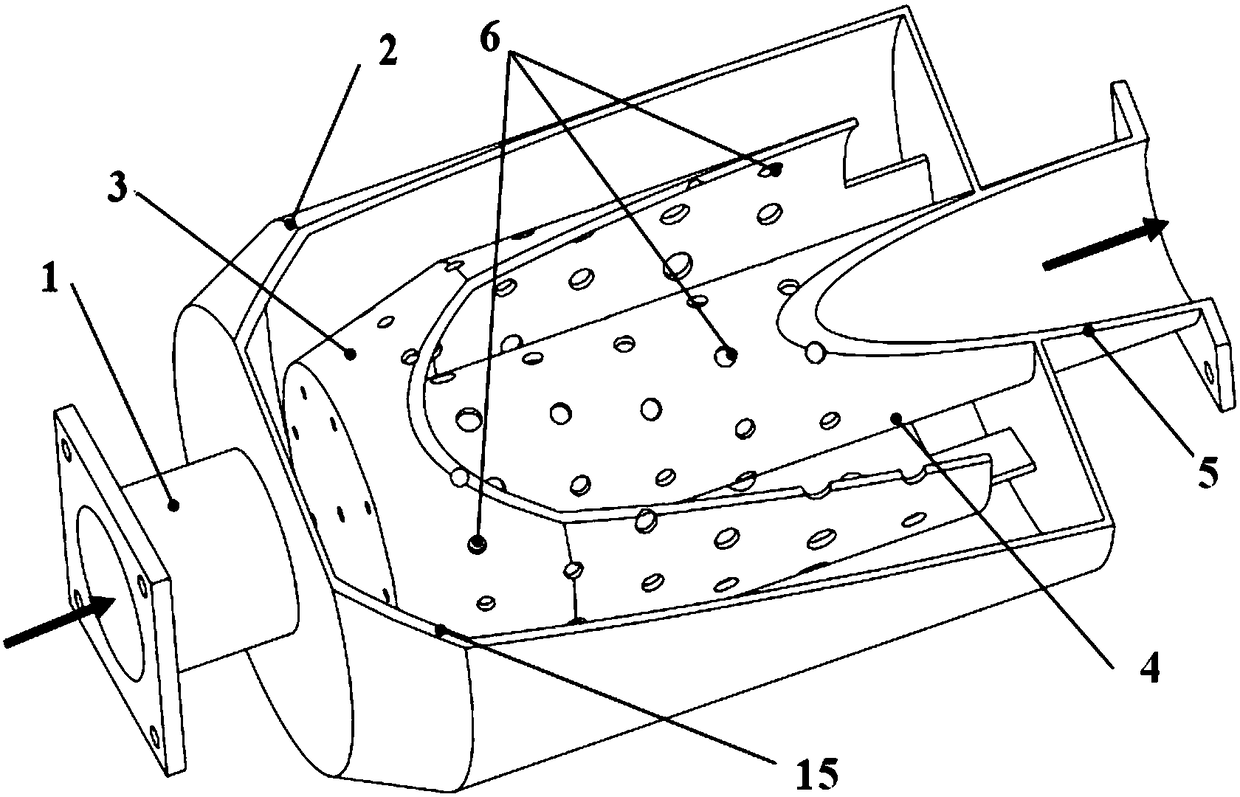

[0029] A gas engine intake mixing chamber of the present invention can refer to the attached Figure 1~7 description, the arrow is the direction of gas movement,

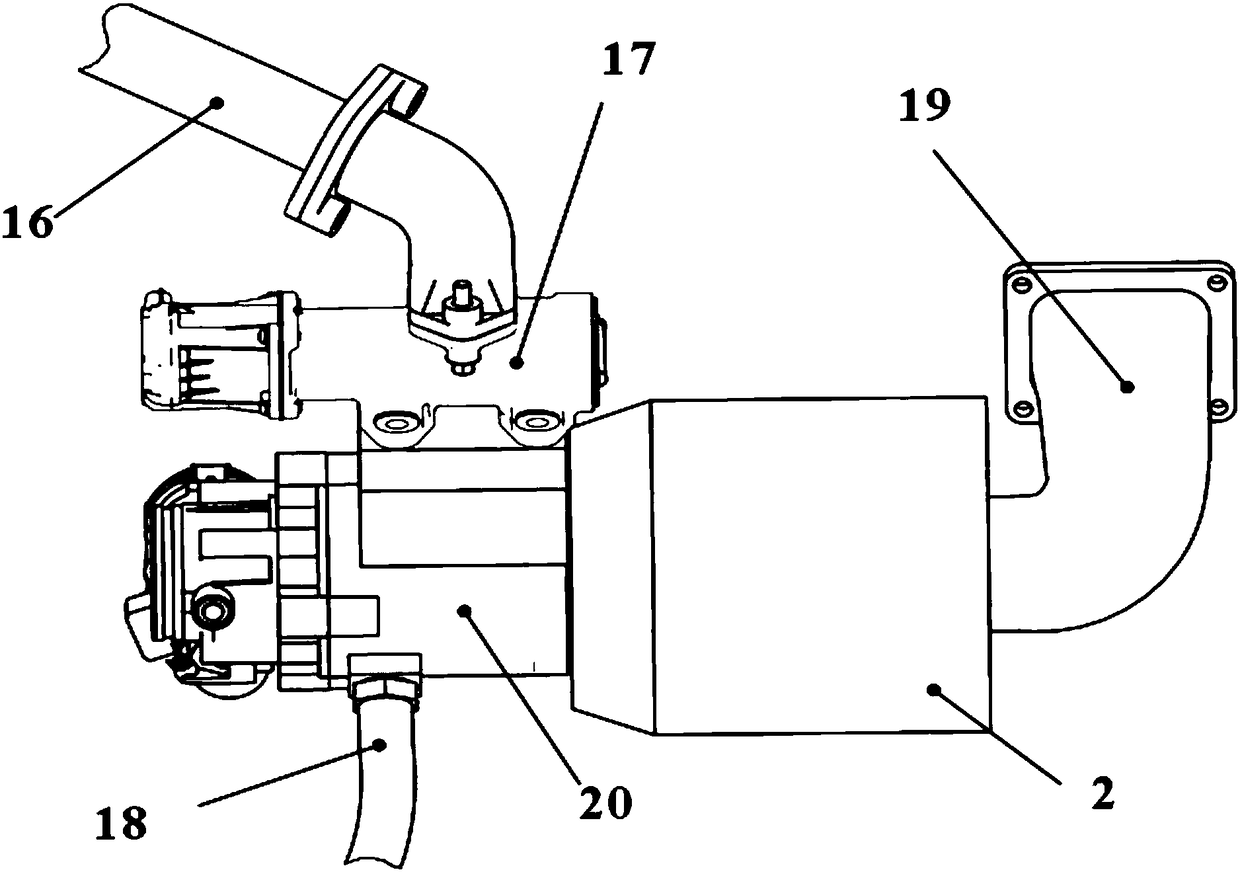

[0030] An air intake mixing chamber for a gas engine, the air intake mixing chamber is arranged between the gas fuel and EGR mixing device and the engine intake pipe elbow 19, including a casing 2, one or more core cover core tube groups ; Figure 1-2 The middle is the structure of a core cover core tube group, Figure 4 The position is a structure of two core-cover core tube groups; when it is larger than two core-cover core tube groups, multiple core-cover core tube groups are set sequentially;

[0031] The casing is sheathed outside the core cover core tube group; each core cover core tube group includes a core cover 3 and a core tube 4, and the core tube 3 is arranged in the core cover 4;

[0032] The housing includes a housing top plate 12, a housing bottom plate 13 and a housing cover plate 23 connecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com