Horizontal type sand pump with double-end-face mechanical seal structure

A mechanical seal and double-end face technology, which is applied to mechanical equipment, non-variable pumps, components of pumping devices for elastic fluids, etc. Sealing end face dry wear and other problems to achieve the effect of improving reliability and maintaining environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described

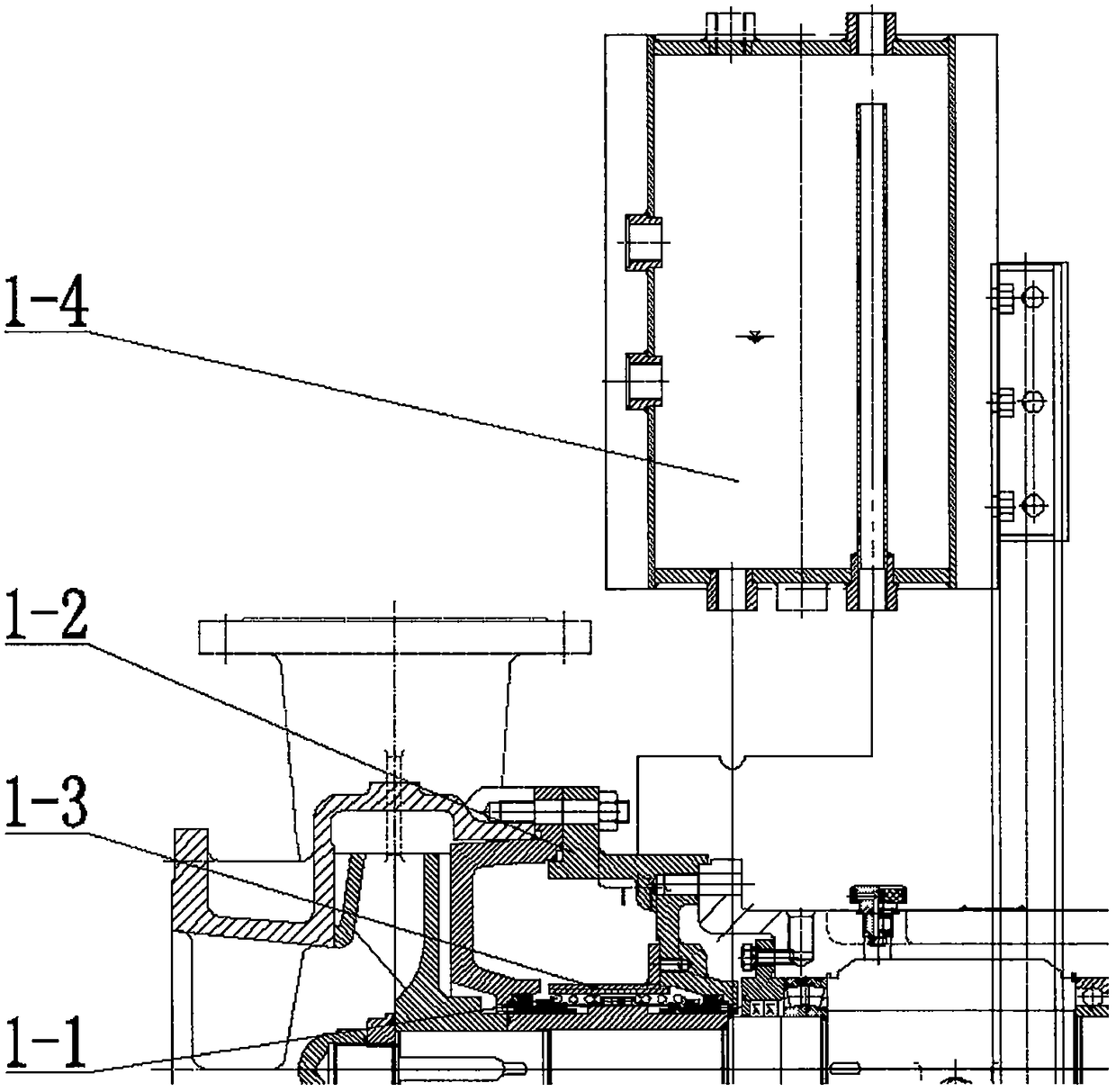

[0030] figure 1 Middle: Horizontal sand pump with double-end mechanical seal structure, including double-end mechanical seal structure 1-1, seal box assembly 1-2, pumping sleeve structure 1-3 and cooling tank assembly 1-4, double The end face mechanical seal structure 1-1 is installed inside the pumping sleeve structure 1-3, together with the pumping sleeve structure 1-3, it is placed inside the sealing box assembly 1-2, and the outside of the sealing box assembly 1-2 is connected with the pipeline through the The cooling tank assembly 1-4, the sealing box assembly 1-2 and the cooling tank assembly 1-4 are filled with engine oil as a circulating cooling medium, and the engine oil passes through the pumping sleeve structure 1-3 outside the double-end mechanical seal structure 1-1 The engine oil in the sealed box assembly 1-2 can flow from one side to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com