Multi-mode clutch executer

A technology for clutches and actuators, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc. Implementation and other issues, to achieve the effect of simple structure, reduce installation process requirements, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

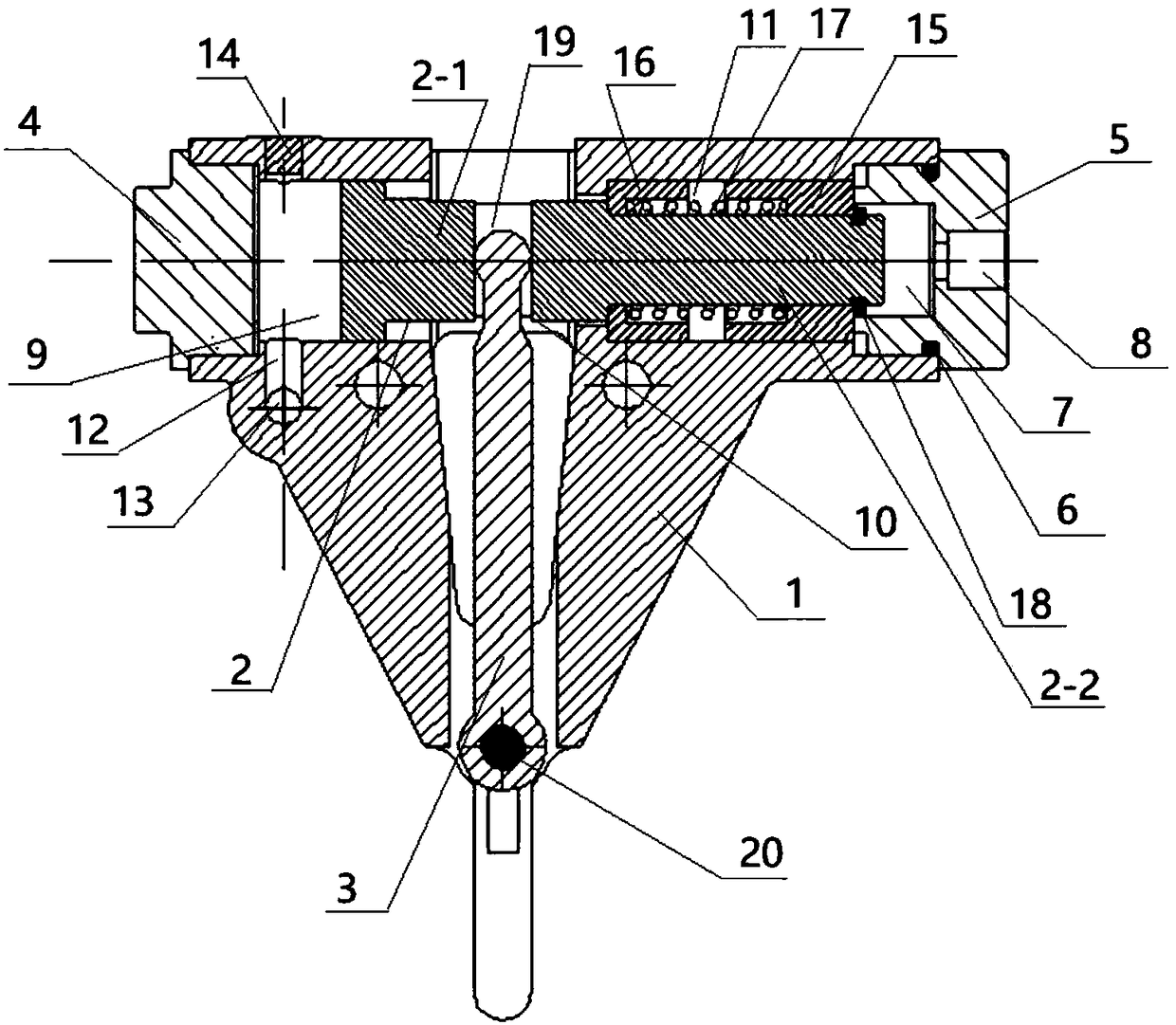

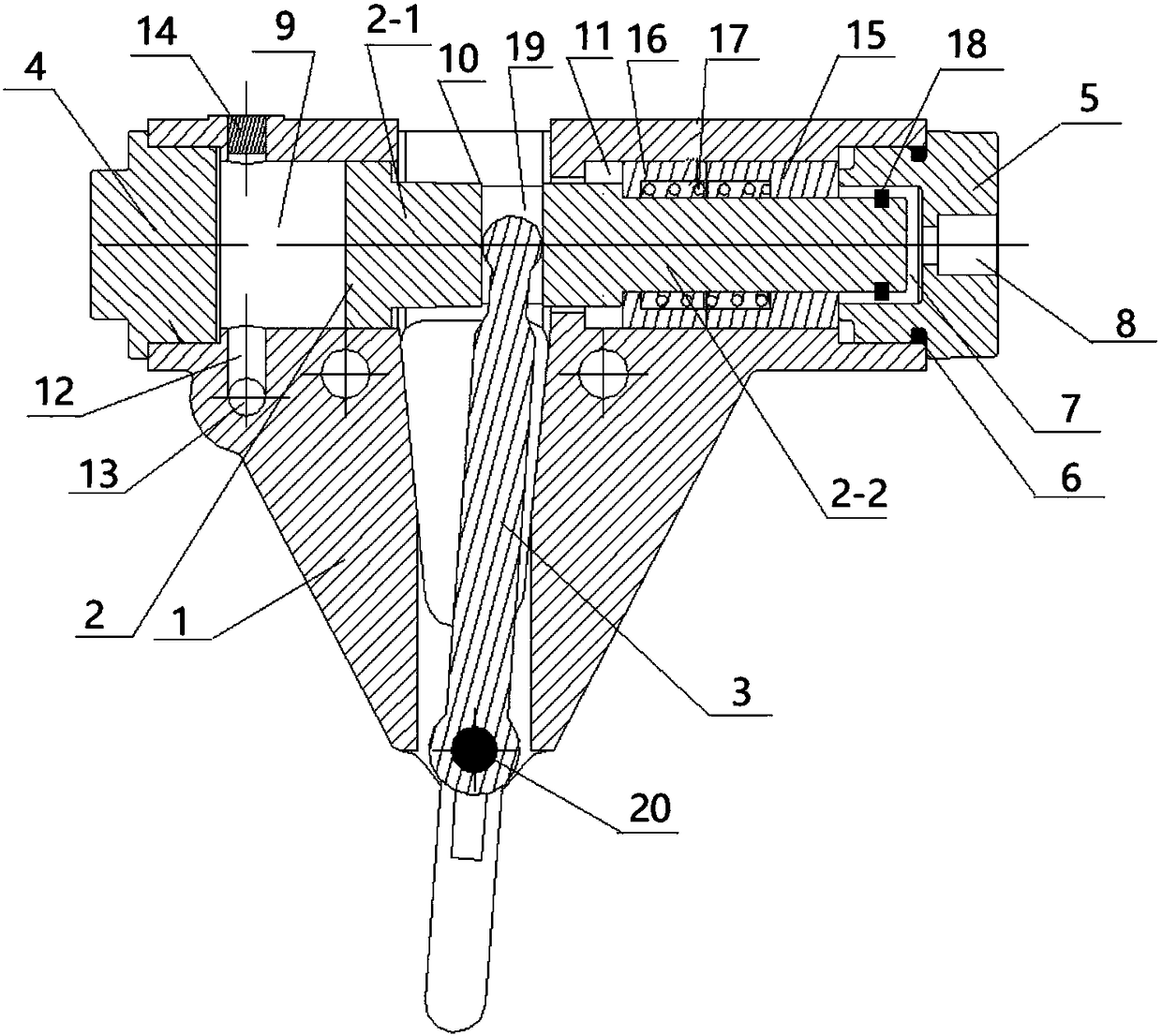

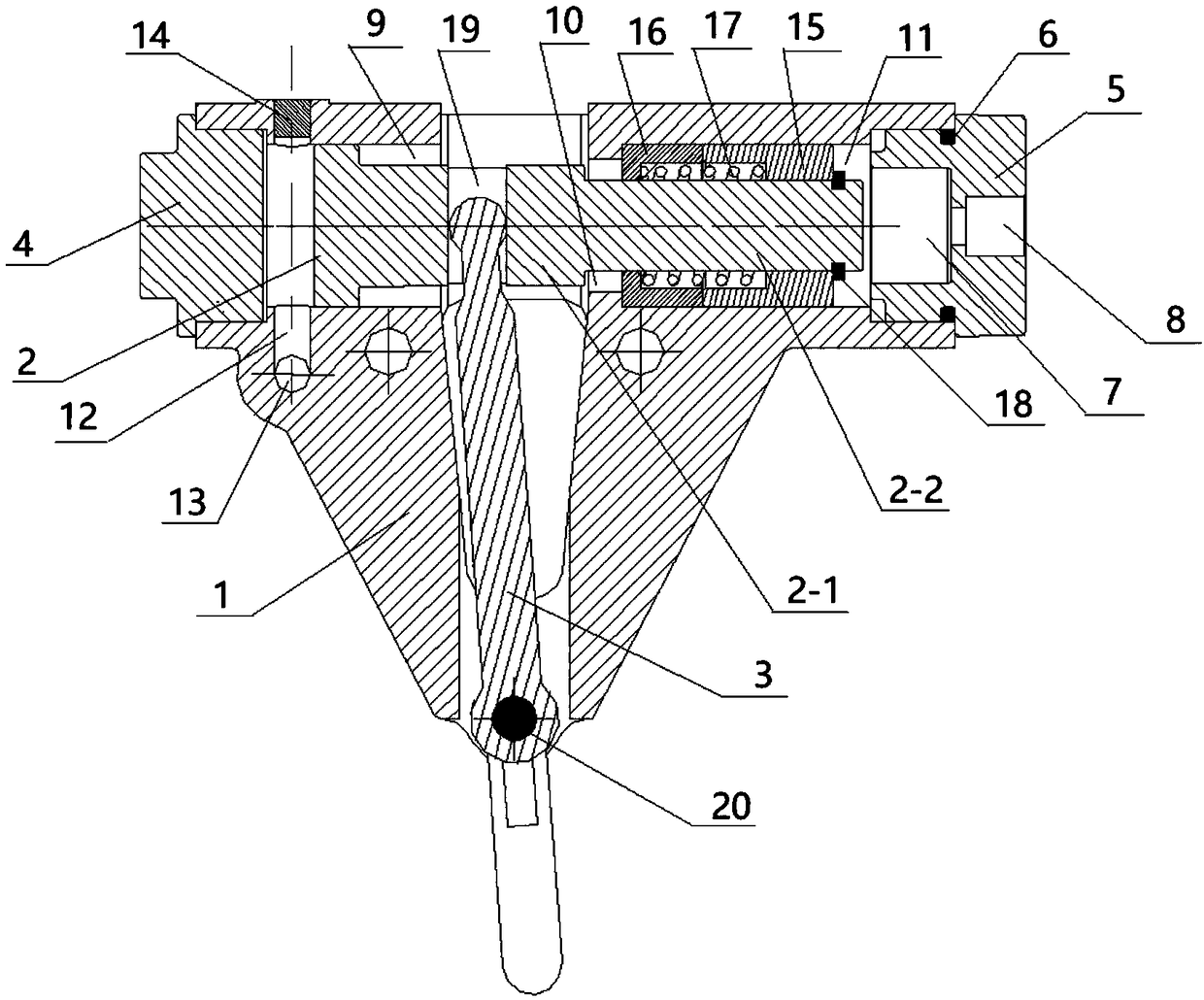

[0016] A multi-mode clutch actuator such as figure 1 As shown, it includes a cavity 1, an actuating plunger 2 and an actuating rod 3, the actuating plunger 2 includes a thick plunger rod 2-1 and a thin plunger rod 2-2, and the thick plunger rod 2-1 as a whole is T-shaped, the end of the thick plunger rod 2-the smaller diameter of the section is fixedly connected with the thin plunger rod 2-2, one end of the cavity 1 is plugged with the first screw plug 4, and the other end of the cavity is plugged with the first screw plug Two screw plugs 5, the second screw plug 5 is covered with an O-ring 6, the O-ring 6 is used to seal the oil passage between the cavity 1 and the second screw plug 5, the end surface of the second screw plug 5 facing inward A groove 7 is opened on the top, a first oil inlet hole 8 is opened on the second screw plug 5 and the first oil inlet hole 8 communicates with the groove 7, and the inside of the cavity 1 is from the first screw plug 4 to the second scre...

Embodiment 2

[0022] A multi-mode clutch actuator, the structure of which is similar to that of the multi-mode clutch actuator in Embodiment 1, the difference is that the first limit stop is a flat plate structure as a whole, and the second limit stop is a whole It is a flat plate structure, the distance between the actuating plunger and the first screw plug, the thick plunger rod of the actuating plunger is placed at one end of the first installation area and the inner wall of the end of the first installation area away from the first screw plug The distance between them, the distance between the actuating plunger and the bottom of the groove of the second screw plug are all equal to the movable distance between the first limit stopper and the second limit stopper.

Embodiment 3

[0024]A multi-mode clutch actuator, its structure is similar to that of the multi-mode clutch actuator in Embodiment 1, the difference lies in: the distance between the actuating plunger and the first screw plug, the actuating column The distance between the plug and the bottom of the groove of the second screw plug is greater than the movable distance between the first limit stopper and the second limit stopper, and the thick plunger rod of the actuating plunger is placed in the first stopper. The distance between one end of the installation area and the inner wall of the end of the first installation area away from the first screw plug is equal to the movable distance between the first limit stopper and the second limit stopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com