Multi-stage transmission structure

A transmission device, transmission stage technology, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of reduced service life, disadvantageous toothed belt, etc., and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

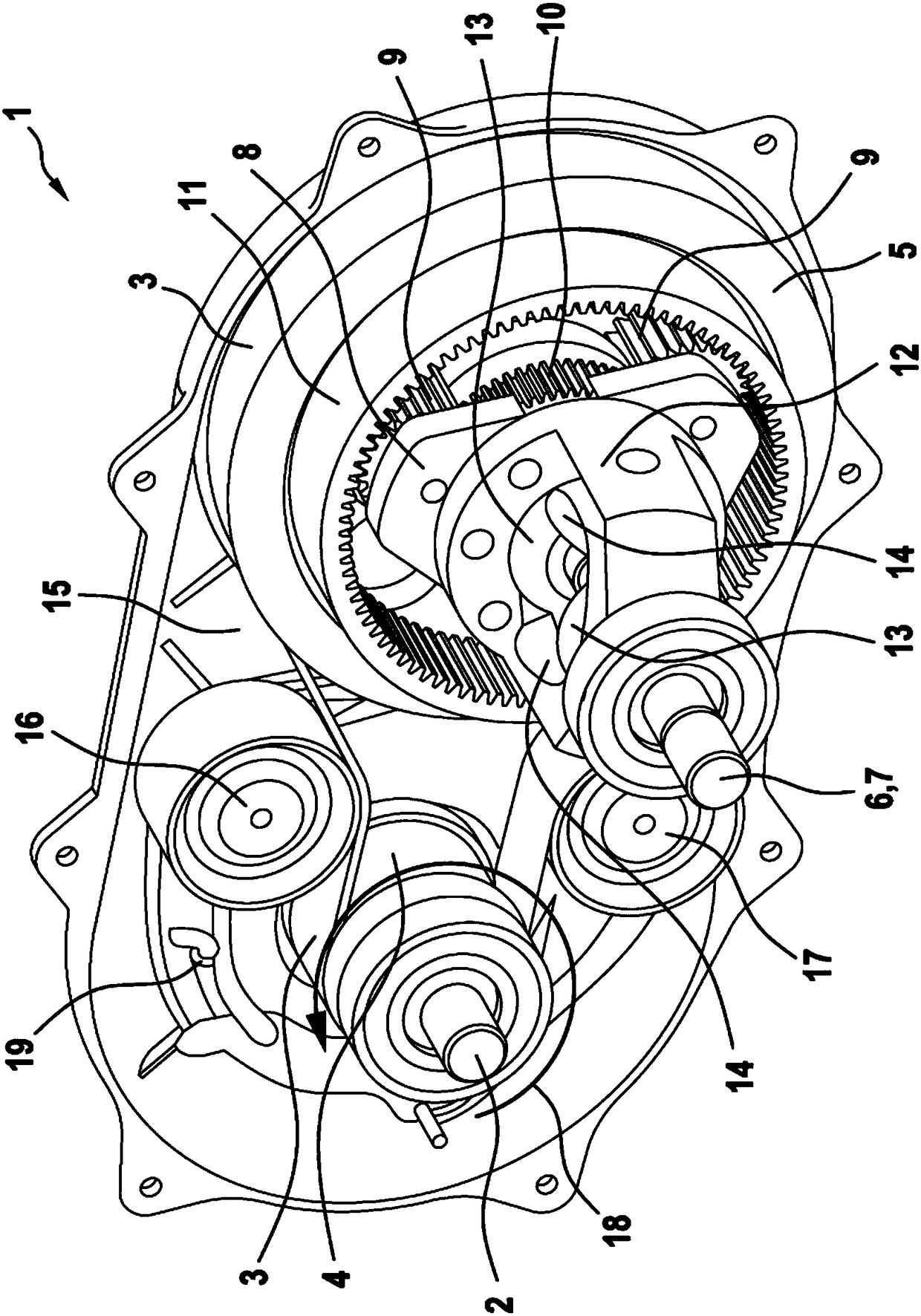

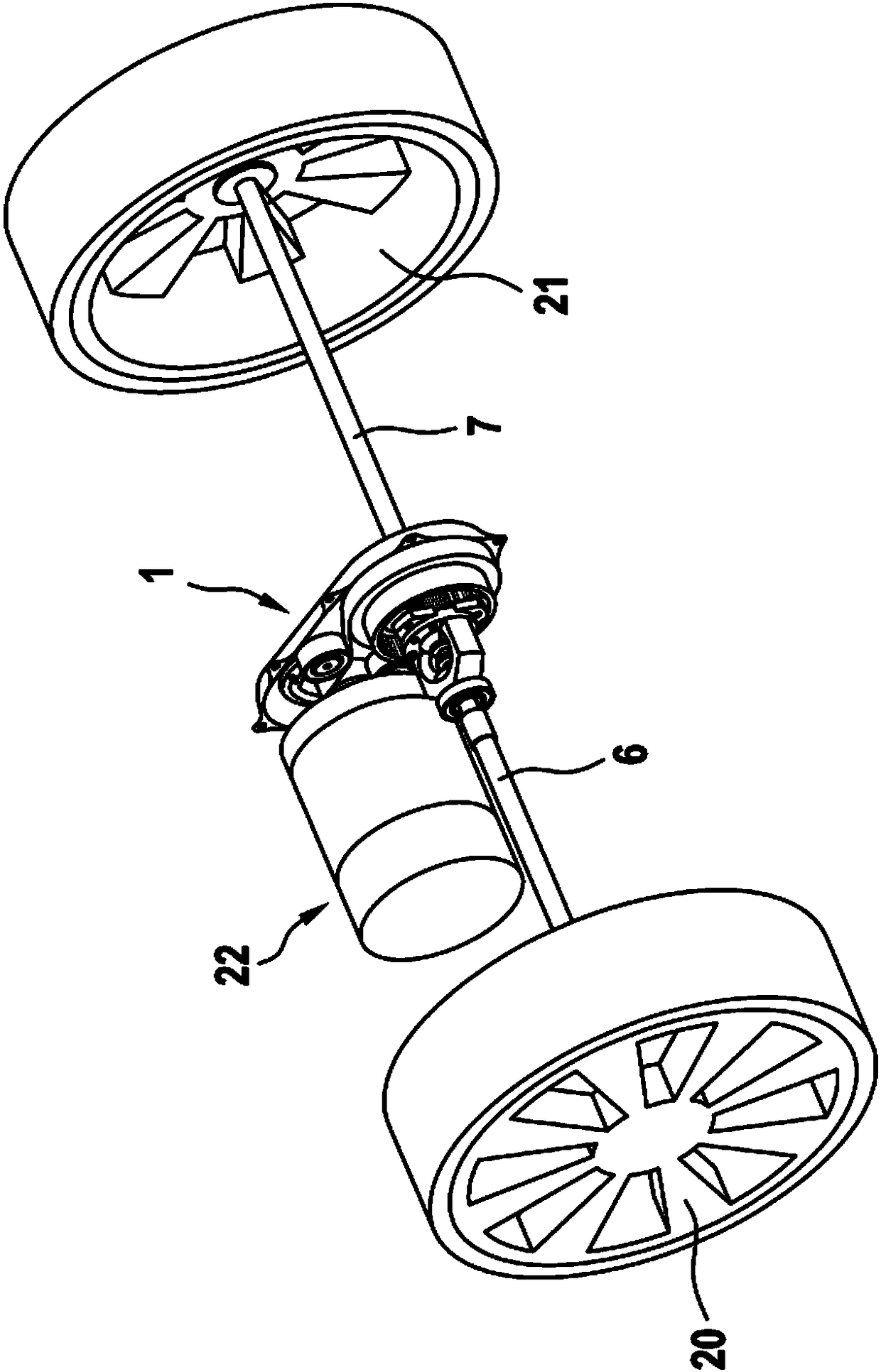

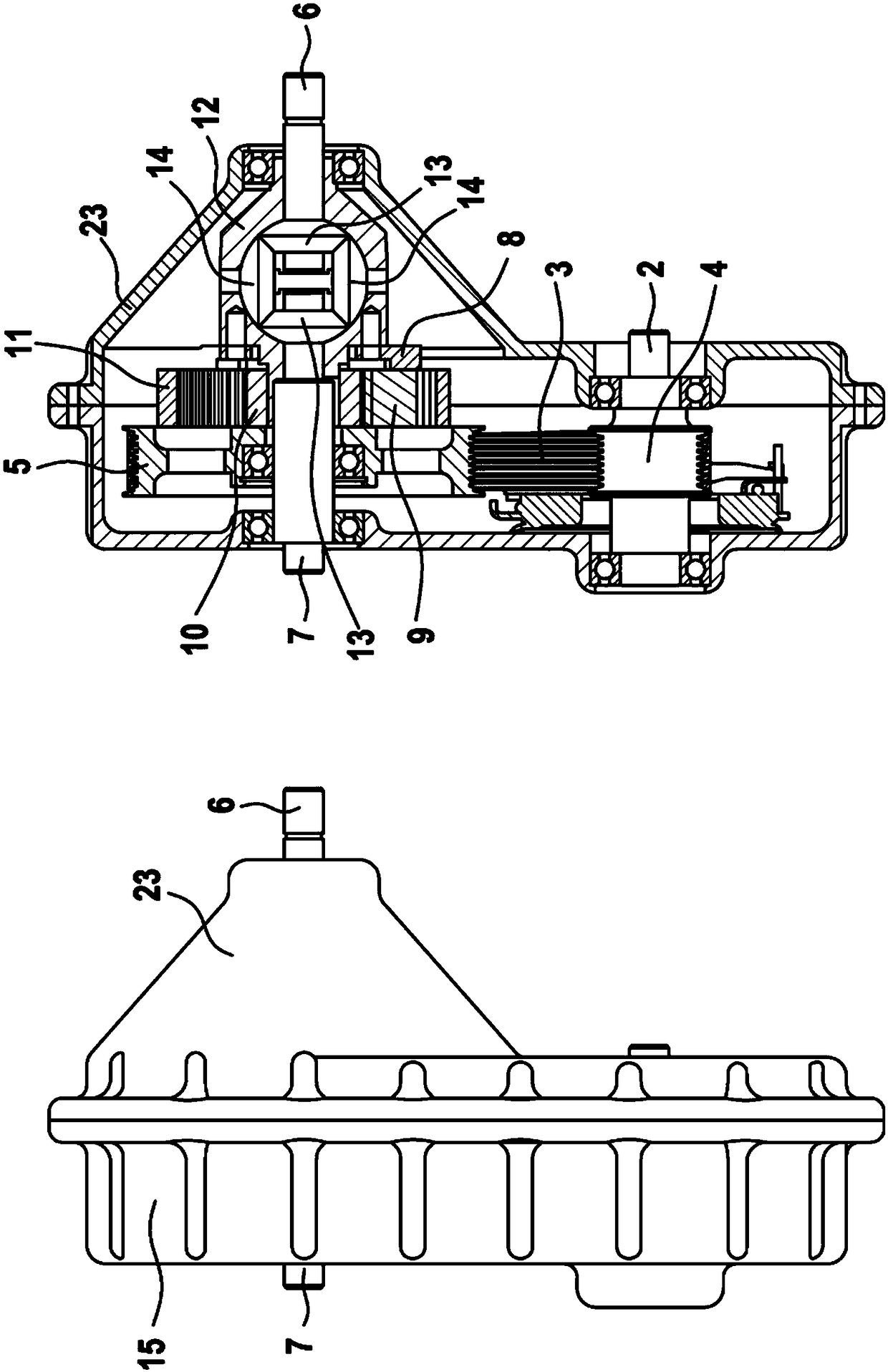

[0046] figure 1 In perspective views, especially with image 3 A constructive embodiment of the drive arrangement 1 according to the invention is shown in conjunction with the view, in which a tension belt drive is firstly provided on the drive side, ie starting from the drive or drive shaft 2 as Variable speed transmission. Here, the tension belt drive has a tension belt in the form of a V-ribbed belt 3 which is wound around the drive pulley 4 and the output pulley 5 of the tension belt drive in a friction fit or form fit, respectively, in order to transmit the torque. and number of revolutions.

[0047] Based on the output side of the tension belt transmission, that is to say in this embodiment, a first planetary gear transmission is arranged between the output pulley 5 and one or two output shafts 6,7 of the tension belt transmission , which has a first planet carrier 8 for accommodating and supporting the first planet wheels 9 . Here, the planetary gear and the sun gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com