Three-stage hydraulic mechanical stepless transmission device for loader

A kind of hydraulic machinery, stepless transmission technology, applied in transmission, fluid transmission, multi-transmission ratio transmission, etc., can solve the problems of complex operation and high power of hydraulic components, so as to improve transmission efficiency, smooth switching, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

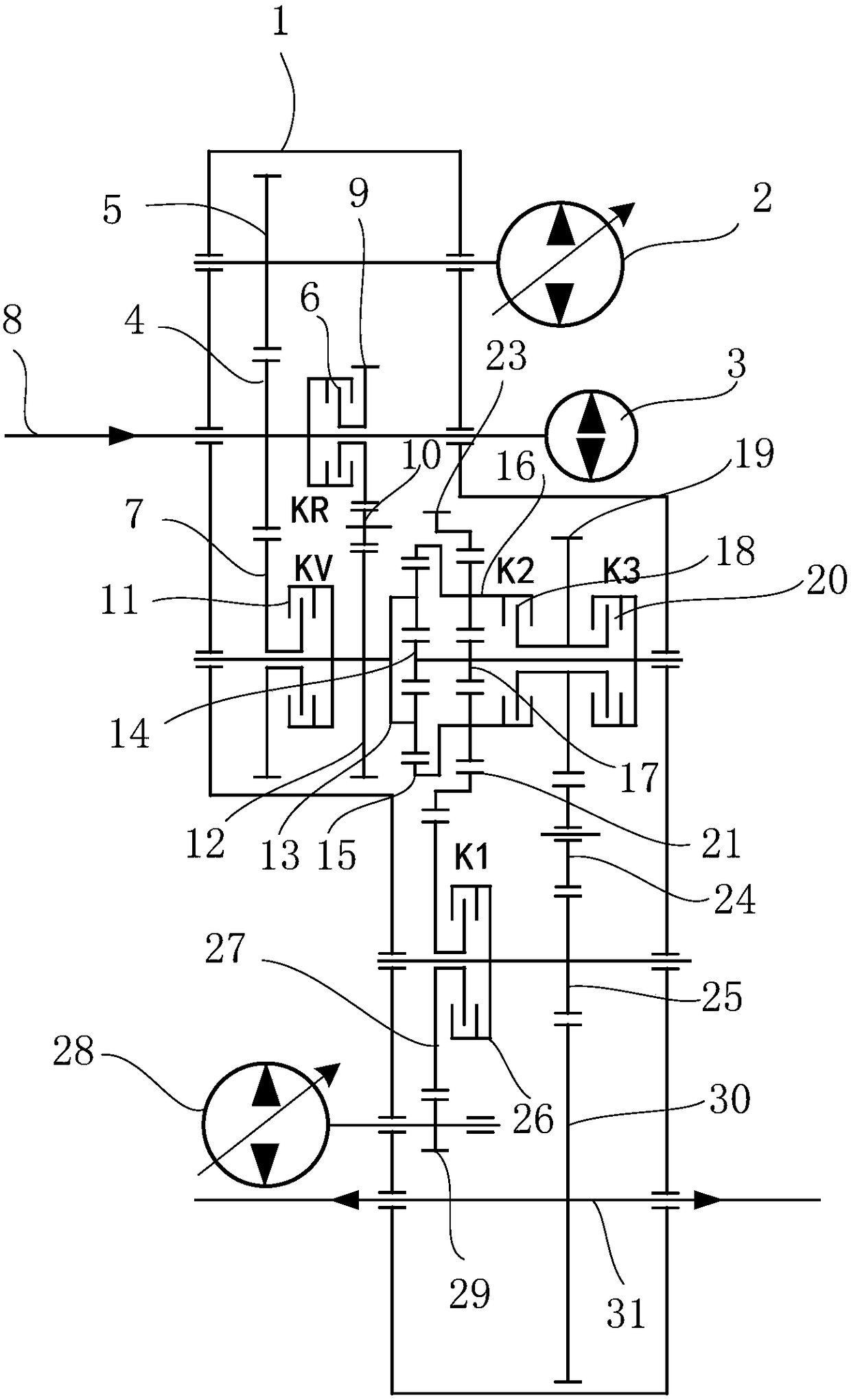

[0032] Such as figure 1 As shown, the three-stage hydraulic-mechanical stepless transmission device of the loader in this embodiment includes a housing 1, a hydraulic speed regulation circuit, a forward and reverse mechanism, a diversion mechanism, a fixed-axis gear transmission system in the hydraulic section, and a hydraulic mechanical section I. Fixed-axis gear transmission system, hydraulic machinery stage II fixed-axis gear transmission system and output part. The hydraulic speed regulating circuit includes a hydraulic pump 2 , an oil charge pump 3 and a variable motor 28 . The forward and reverse mechanism includes a main input shaft 8 , a fourth gear 4 , a seventh gear 7 , a ninth gear 9 , a tenth gear 10 , a twelfth gear 12 , a first KV clutch 11 and a first KR clutch 6 . The flow-sharing mechanism includes a first planetary carrier 13 , a twenty-third gear 23 , a twenty-first ring gear 21 , a second planetary carrier 16 , a second sun gear 17 and a nineteenth gear 19...

Embodiment 2

[0050] This embodiment is an embodiment improved on the basis of the first embodiment.

[0051] Such as Figure 6As shown, the three-stage hydraulic-mechanical stepless transmission device of the loader in this embodiment includes a housing 1, a hydraulic speed regulation circuit, a forward and reverse mechanism, a diversion mechanism, a fixed-axis gear transmission system in the hydraulic section, and a hydraulic mechanical section I. Fixed-axis gear transmission system, hydraulic machinery stage II fixed-axis gear transmission system and output part. The hydraulic speed regulating circuit includes a hydraulic pump 2 , an oil charge pump 3 and a variable motor 28 . The forward and reverse mechanism includes a main input shaft 8 , a fourth gear 4 , a seventh gear 7 , a ninth gear 9 , a tenth gear 10 , a twelfth gear 12 , a first KV clutch 11 and a first KR clutch 6 . The flow-sharing mechanism includes a first planetary carrier 13 , a twenty-third gear 23 , a twenty-first ri...

Embodiment 3

[0056] This embodiment is an embodiment improved on the basis of the first embodiment.

[0057] Such as Figure 7 As shown, the three-stage hydraulic-mechanical stepless transmission device of the loader in this embodiment includes a housing 1, a hydraulic speed regulation circuit, a forward and reverse mechanism, a diversion mechanism, a fixed-axis gear transmission system in the hydraulic section, and a hydraulic mechanical section I. Fixed-axis gear transmission system, hydraulic machinery stage II fixed-axis gear transmission system and output part. The hydraulic speed regulating circuit includes a hydraulic pump 2 , an oil charge pump 3 and a variable motor 28 . The forward and reverse mechanism includes a main input shaft 8 , a fourth gear 4 , a seventh gear 7 , a ninth gear 9 , a tenth gear 10 , a twelfth gear 12 , a first KV clutch 11 and a first KR clutch 6 . The flow-sharing mechanism includes a first planetary carrier 13 , a twenty-third gear 23 , a twenty-first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com