Floor brush for surface cleaning device

A technology of surface cleaning device and rolling brush, which is applied in the direction of cleaning carpets, cleaning floors, cleaning equipment, etc. It can solve the problems that the suction cannot form wind speed flow, the gap is narrowed, and the cleaning effect is poor, so as to improve the capture and cleaning ability and improve the jam dead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

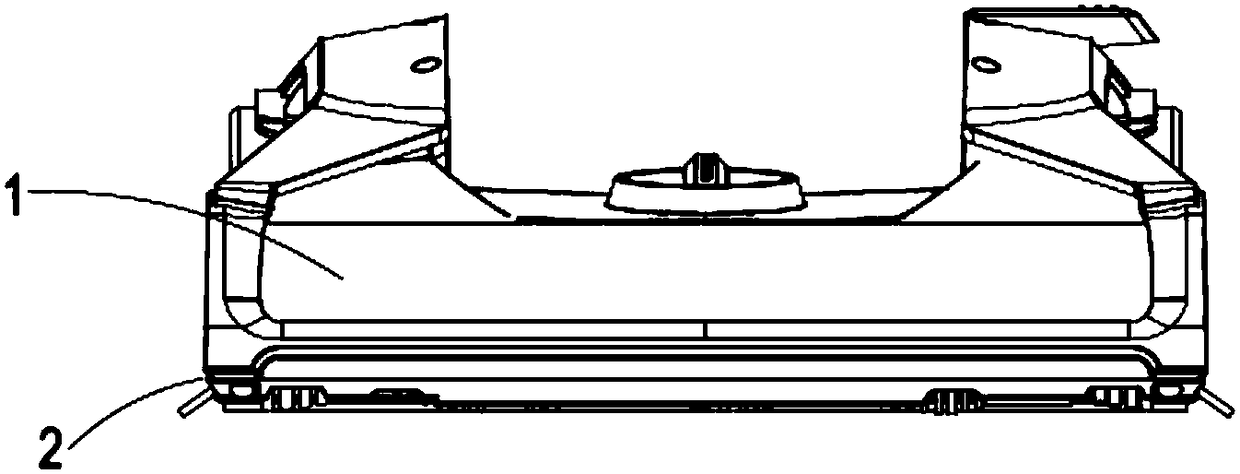

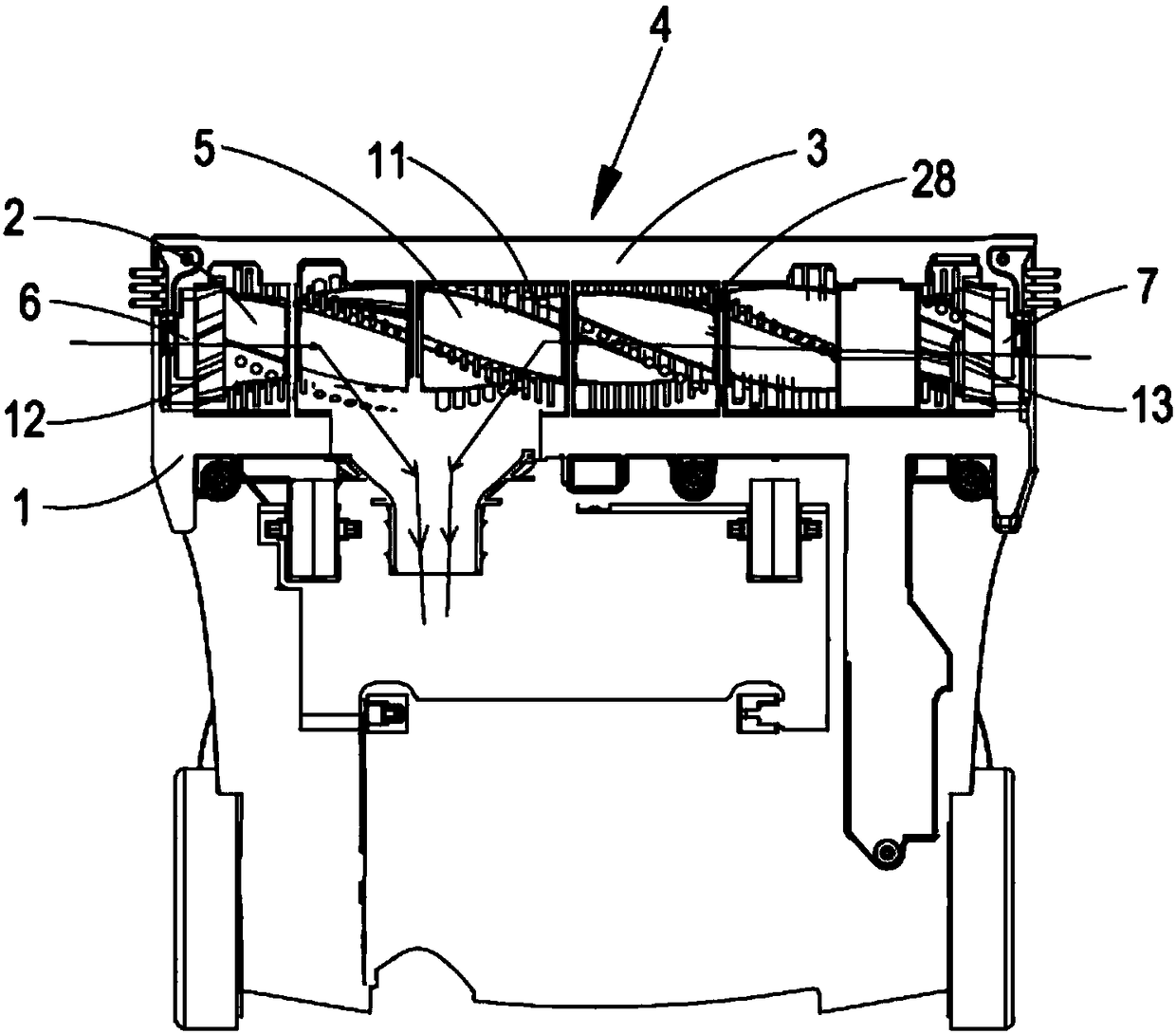

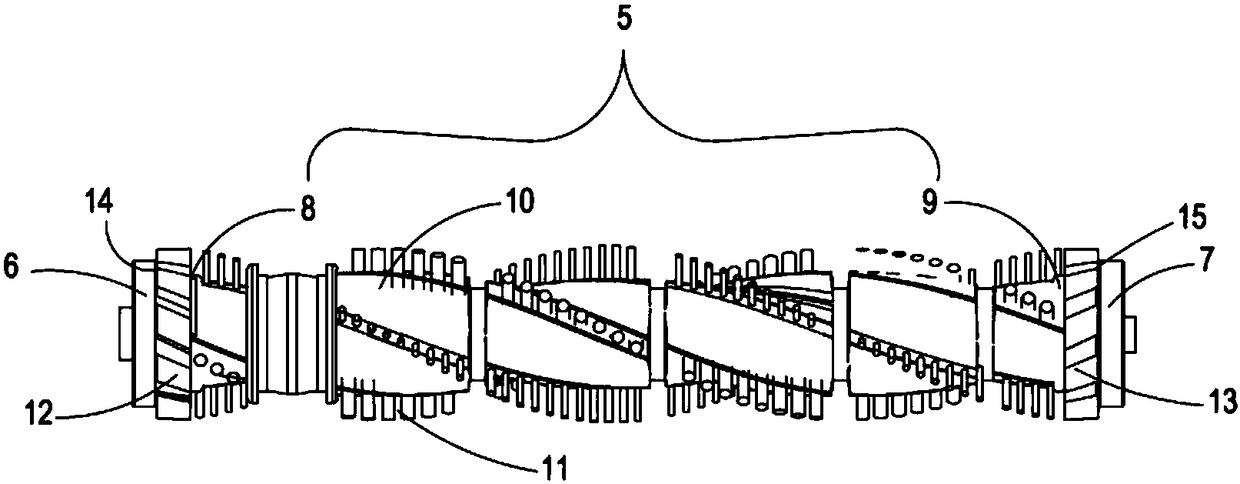

[0023] In this example, if Figure 1-Figure 5 The floor brush shown can be used on surface cleaning devices such as vacuum cleaners, steam cleaners, etc. It has a housing 1, the front part of the housing 1 is provided with a dust suction port 2 facing downwards, and the inner side of the housing 1 is adjacent to the dust suction port 2. A roller brush installation cavity 3 is installed in the roller brush installation cavity 3 The rolling brush assembly 4, the air flow is formed between the rolling brush installation chamber 3 and the dust suction port 2, the rolling brush assembly 4 includes a rolling brush body 5 capable of rotating around a transverse axis line, and the two sides of the rolling brush body 5 have first ends The cover 6 and the second end cover 7, the rolling brush body 5 has a first side end 8, a second side end 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com