Wire electrode tension control method and device for micro electrolytic wire cutting

A tension control, wire electrode technology, applied in electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problems of low repeatability, poor resistance to deformation and disturbance, low clamping efficiency, etc. Anti-deformation, precise and constant tension force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

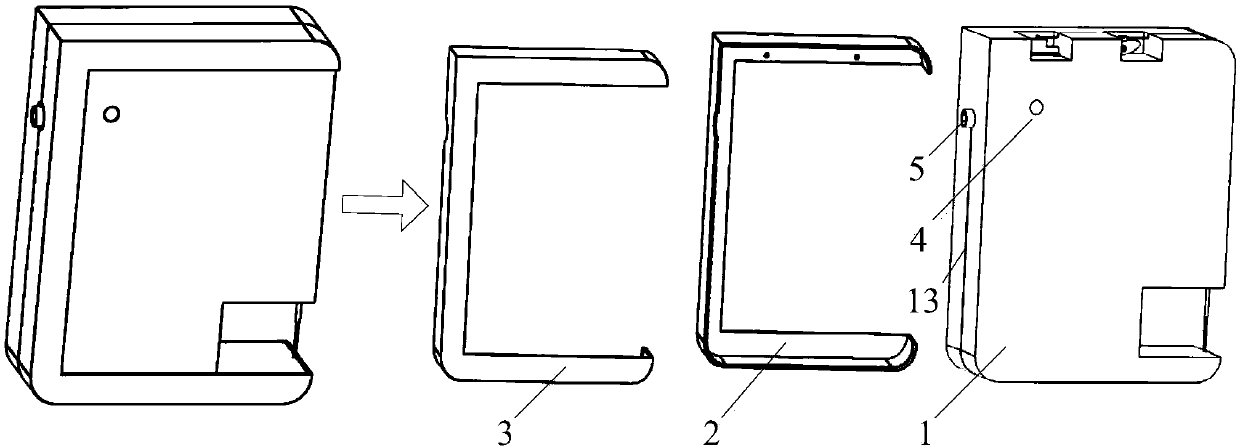

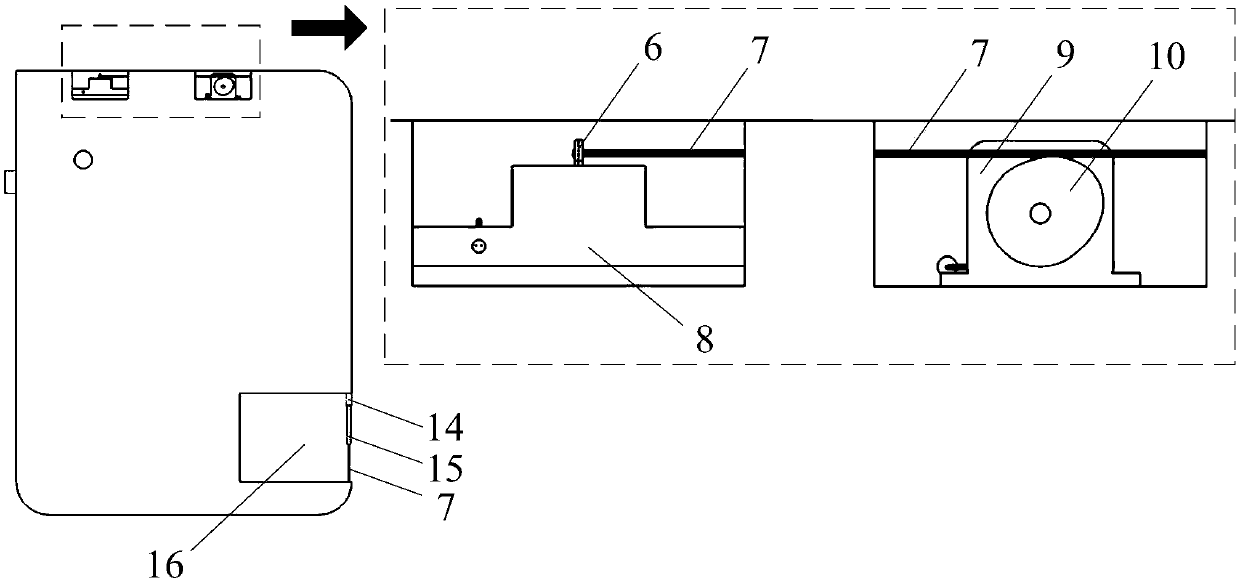

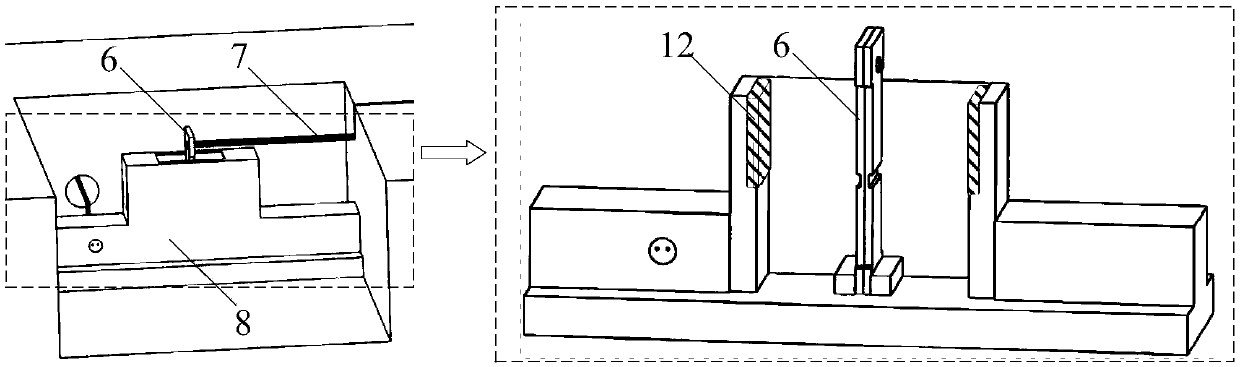

[0023] As shown in the figure, the wire electrode tension control device for micro-electrolytic wire cutting of the present invention mainly includes: a base 1, an insulating protective cover 2 and 3, a fastening conductive screw 5, a wire electrode 7, a miniature capacitive sensor 8, a miniature Servo motor 11, miniature cam 10, double-layer embedded insulating tubes 14 and 15; wherein, fixed pole plate 12 and movable pole plate 6 are installed in miniature capacitive sensor 8.

[0024] After one end of the wire electrode 7 is sprayed with an insulating layer, it is clamped on the movable plate 6 in the miniature capacitive sensor 8, first passes through the surface of the miniature cam 10 along the limit groove 13, and then passes through the embedded double-layer insulating tube 14 and 15, then pass through the notch structure 16, and finally go around to the fastening conductive screw 5. The purpose of spraying an insulating layer on one end of the movable plate 6 for conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com