Optimized operation method for electric bus charging and battery swapping station

An electric bus, charging and swapping station technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve problems such as large space limitations of optimization strategies, uneven use of battery packs, and increased battery pack loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

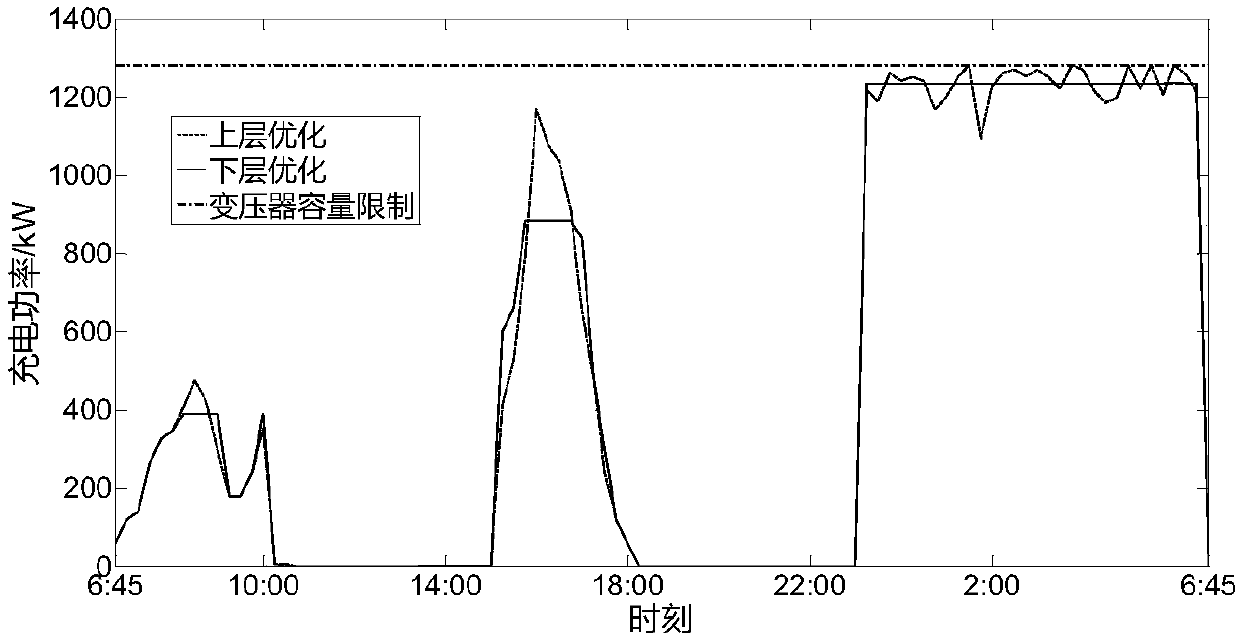

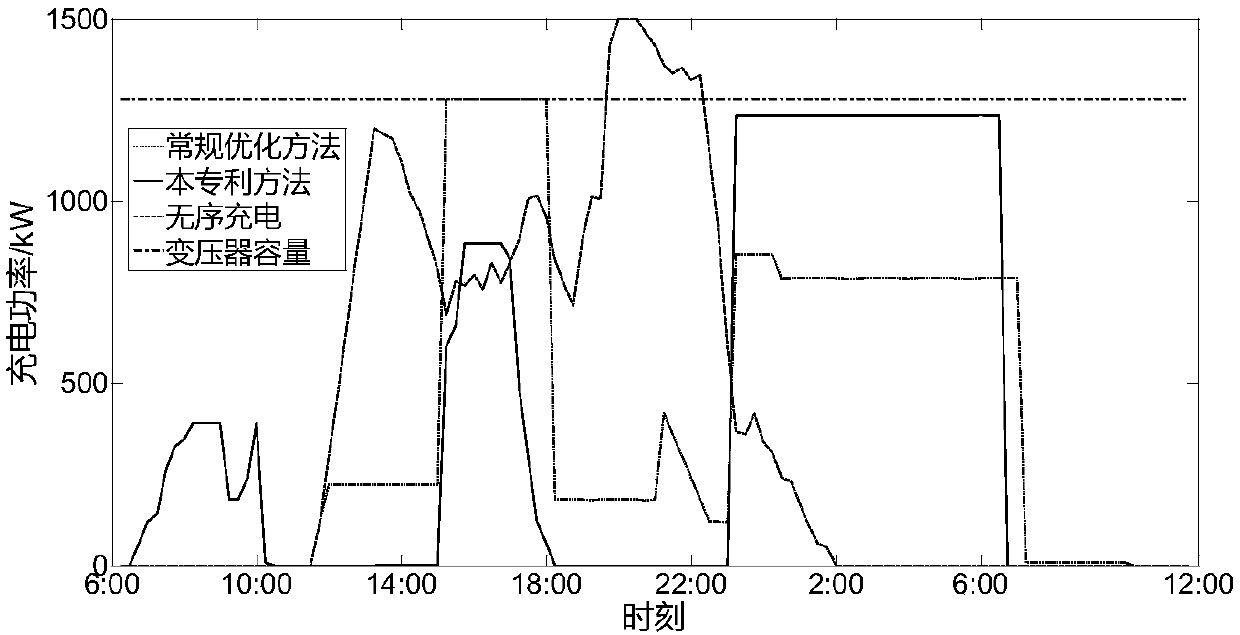

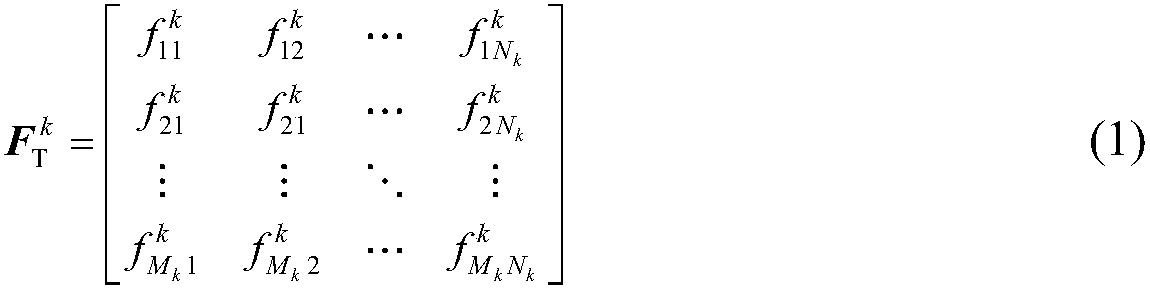

[0081] A. Taking the electric bus charging and swapping station serving two bus lines (K=2) as the research object, a dedicated distribution transformer (without conventional load) is used in the station; Δt=15min is an optimal control period, that is, a single The day is divided into 96 periods. The relevant parameters are set as follows: electric bus related parameters, including: battery pack capacity C B is 180kWh, and the average unit power consumption of the vehicle is C E Take 1.25kWh / km (this example assumes that the power consumption per unit mileage of the vehicle is proportional to the one-way driving time), the minimum state of charge SOC of the battery pack min Take 0.2; electric bus charging station related parameters: the number of charging piles in the station N cha is 25 seats, its maximum and minimum charging power P max ,P min 60kW and 0kW respectively, charging efficiency η cha is 0.95, the number of backup battery packs is 25 sets, and the number K of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com