Single-face adhesive tape case sealer

A tape, single-sided technology, applied in the field of single-sided tape sealing device, can solve the problems of blocked production line, not tight sealing, high error rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

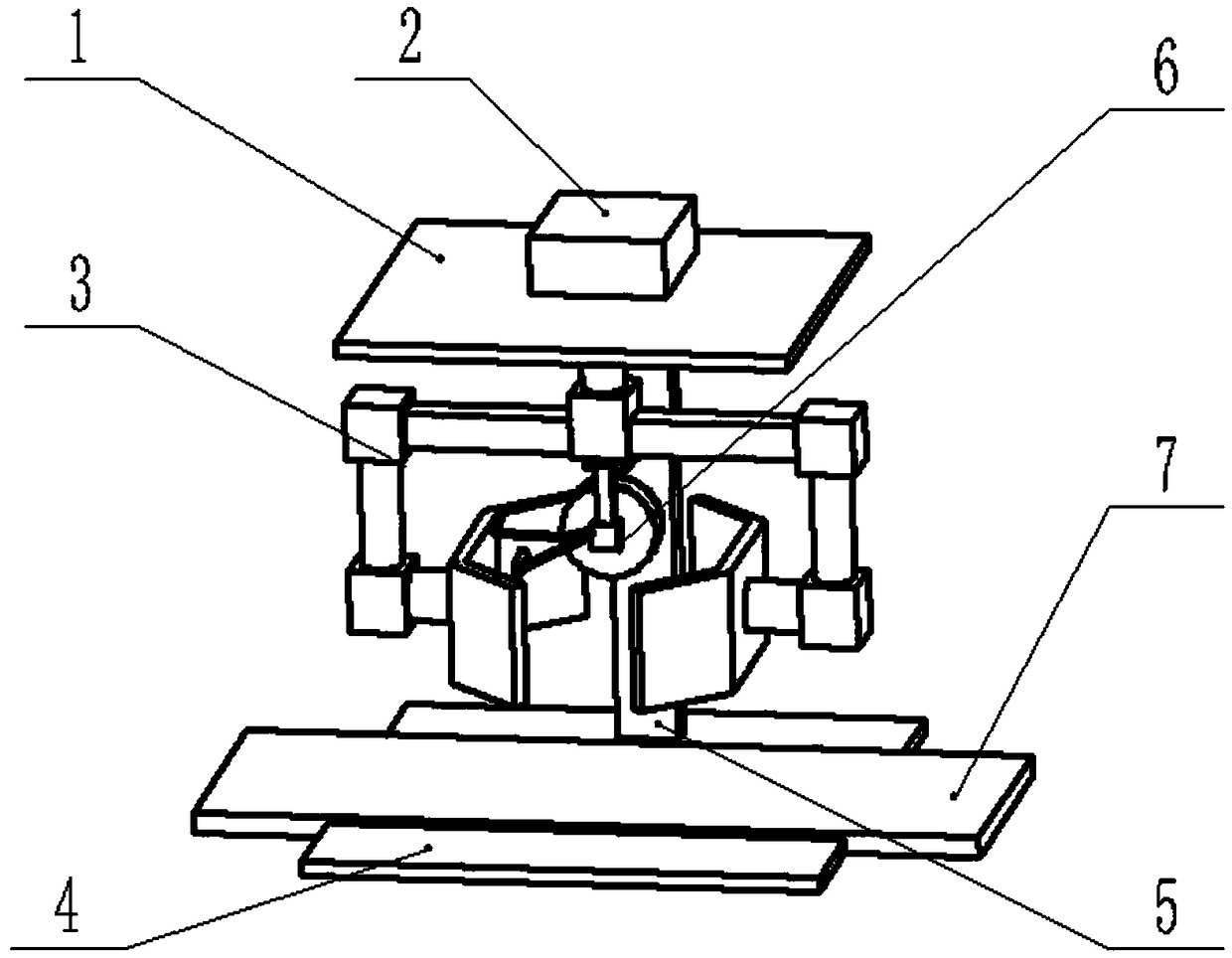

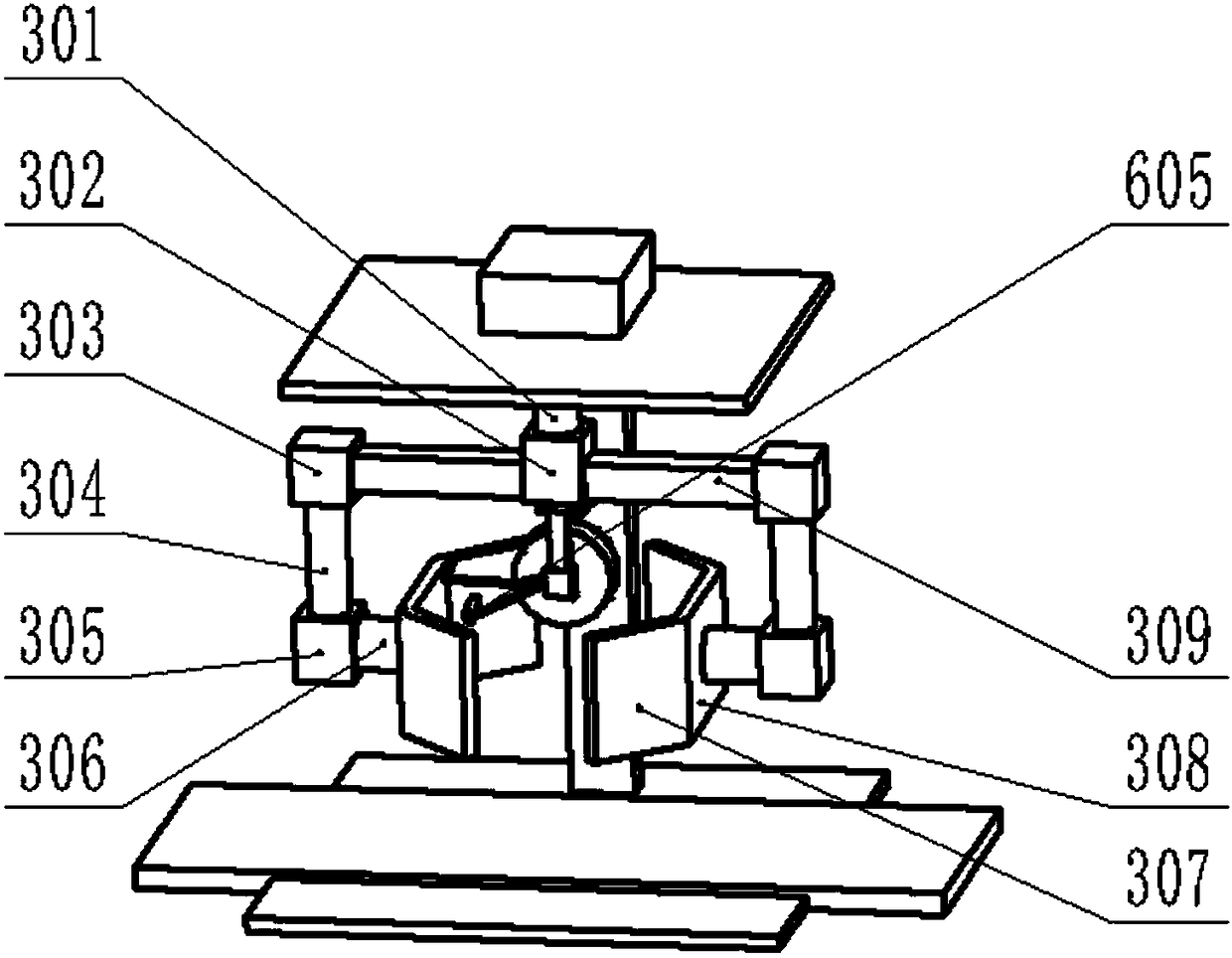

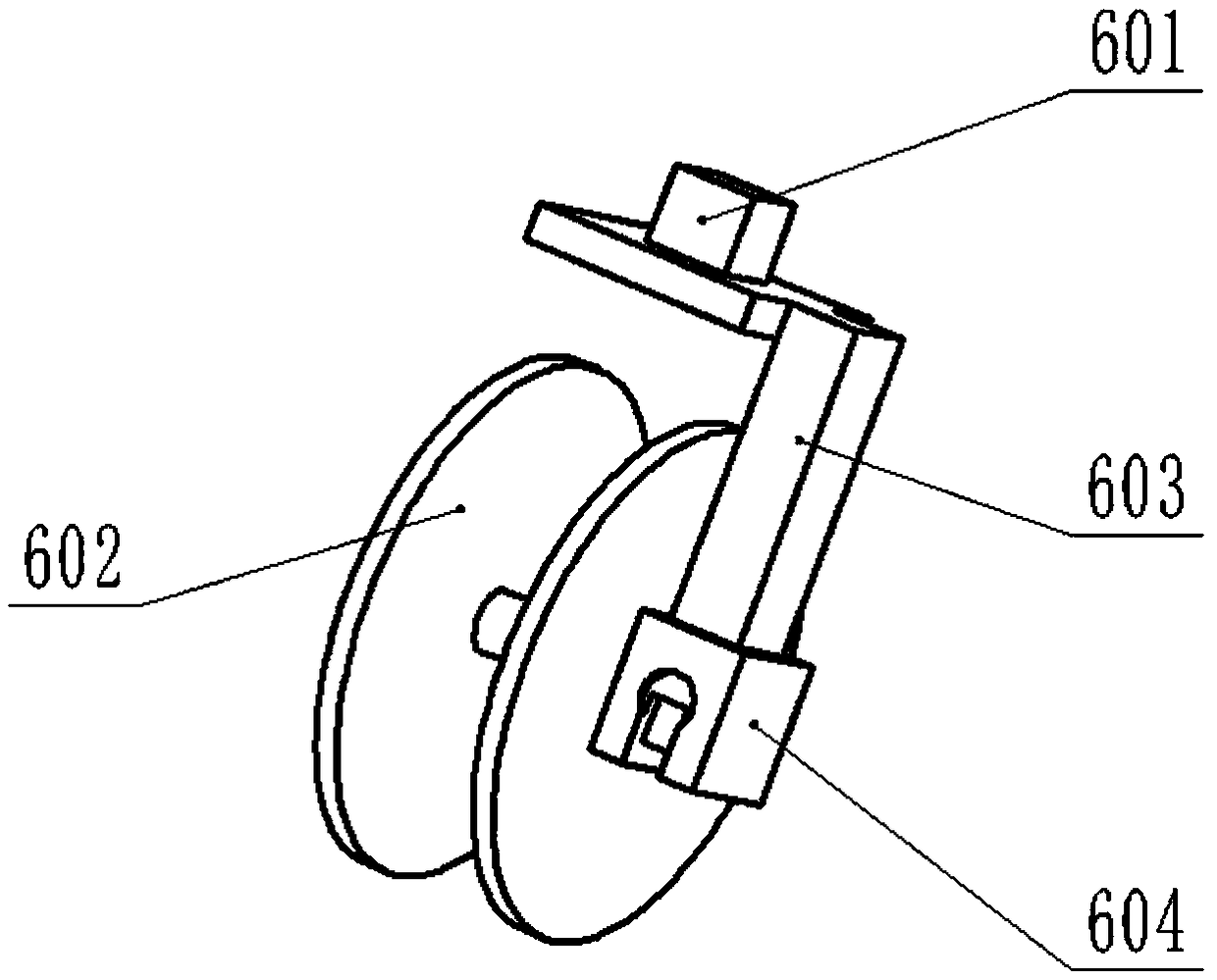

[0020] A single-sided tape sealing device is composed of a top plate 1, a fuel tank control module 2, a hydraulic clamping device 3, a bottom plate 4, a support column 5, a sealing device 6 and a conveyor belt 7, and the conveyor belt 7 is arranged on the bottom plate. In the middle, the top plate 1 is connected with the bottom plate 4 through the support column 5, the fuel tank control module 2 is installed on the upper surface of the top plate 1, and the hydraulic clamping device 3 has No. 1 hydraulic cylinder 301 and No. 2 hydraulic cylinder 304 , No. 3 hydraulic cylinder 306, No. 1 hydraulic pump 302, No. 2 hydraulic pump 303, No. 3 hydraulic pump 305, front baffle 308, side baffle 307 and connecting rod 309, No. 1 hydraulic cylinder 301 is connected to the top plate 1, a The No. 2 hydraulic pump 302 and the No. 2 hydraulic pump 303 are connected together by the connecting rod 309, the No. 2 hydraulic pump 303 and the No. 3 hydraulic pump 305 are connected together by the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com