Fiber drawing and annealing device

An annealing device and optical fiber technology, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of warpage attenuation, unstable optical fiber parameters, and failure to meet target requirements, and achieve the effect of improving quality and attenuation characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

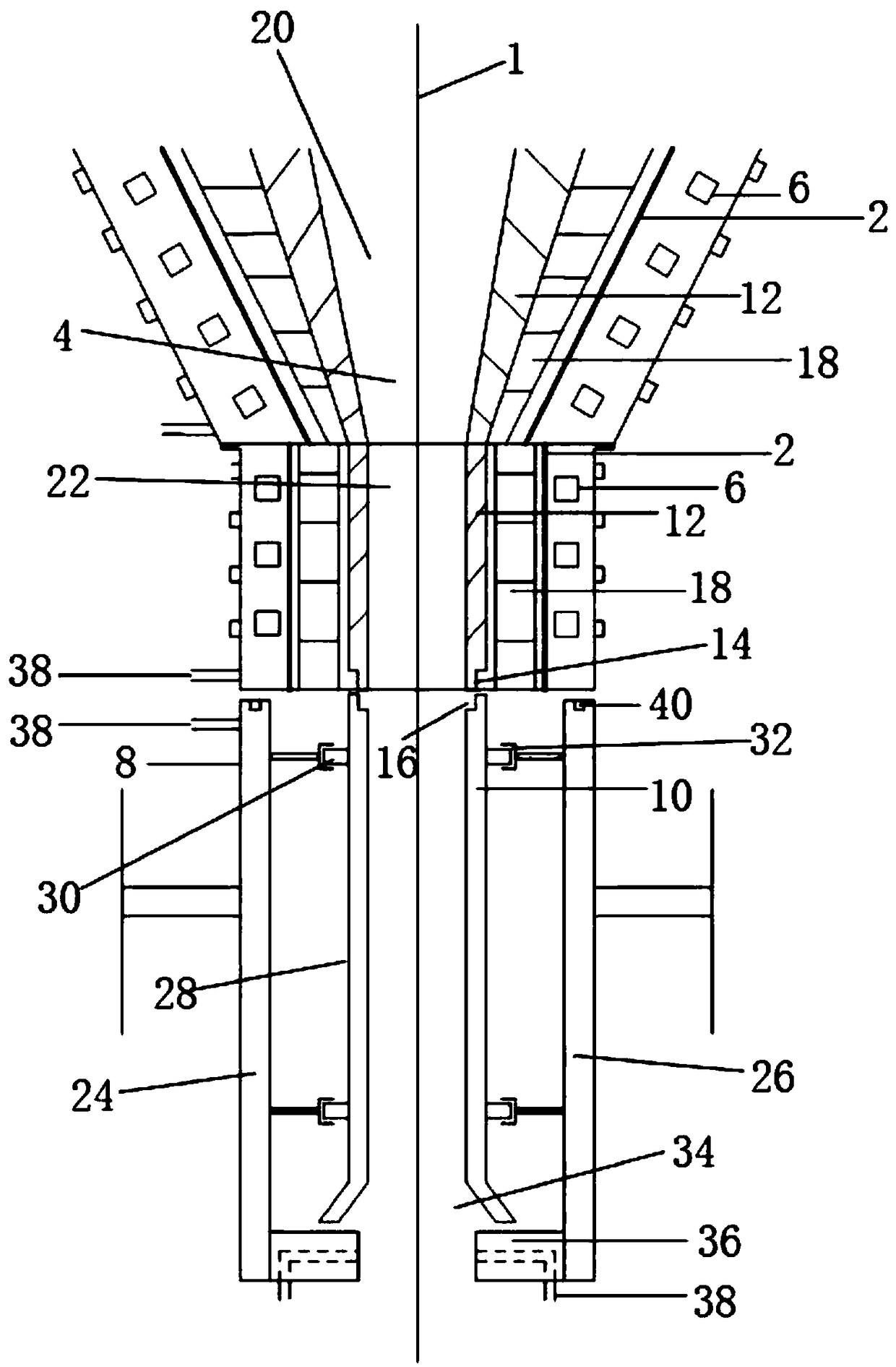

[0020] Such as figure 1 As shown, this embodiment discloses an optical fiber drawing and annealing device, which includes an annealing tube 2 and an annealing auxiliary device 8. The top of the annealing tube 2 is connected to the drawing furnace, and the annealing auxiliary device 8 is sealed and connected to the bottom of the annealing tube 2. The bottom of the auxiliary device 8 is screwed to the base 36, and the entire annealing device is supported by the base 36. The above-mentioned annealing tube 2 is provided with an axial cavity 4, the cavity wall of the above-mentioned axial cavity 4 is provided with a graphite part 12, and the above-mentioned annealing auxiliary device 8 is provided with a graphite liner 10, and the above-mentioned liner 10 is connected with the axial cavity 4 are arranged coaxially, and the end of the above-mentioned graphite piece 12 is connected with the liner 10. The optical fiber 1 enters the axial cavity 4 after being drawn out of the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com