Filter screen structure applied to lubricating oil pump

A technology of lubricating oil pump and filter screen, which is applied to the components of the pumping device for elastic fluid, lubrication pump, pump element, etc., can solve the problem of poor filter taper guarantee, reduced use reliability, and delamination of mesh edges. and other problems, to achieve the effect of improving efficiency and effect, reducing volume and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

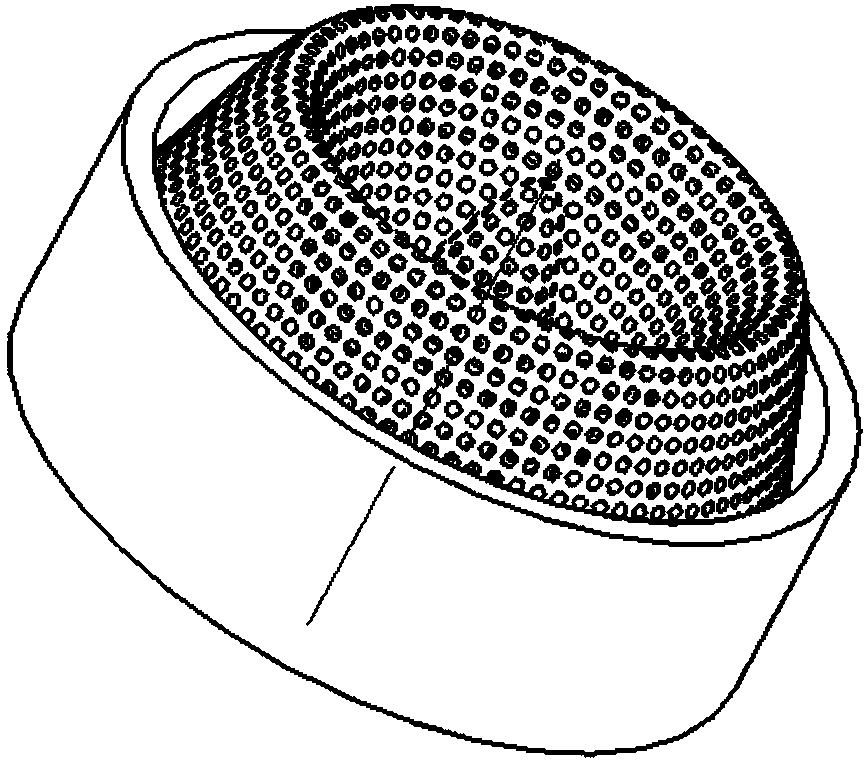

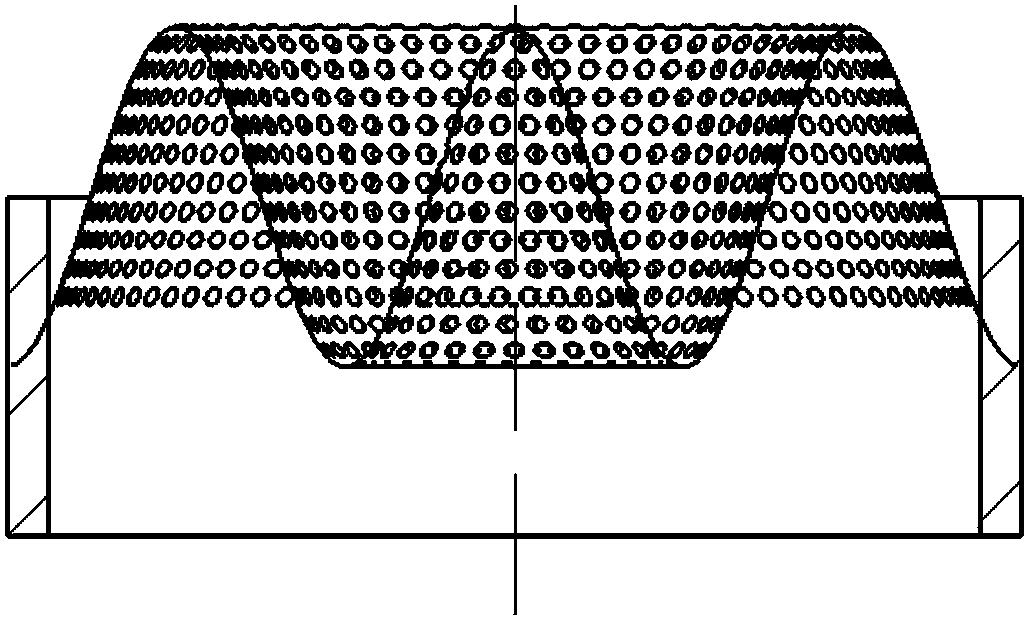

[0012] As shown in the figure, a filter screen structure applied to lubricating oil pumps is an integrated structure, including a filter screen 2 and a reinforcement ring 1, the filter screen 2 is fixed on the reinforcement ring 1, and the cross section of the filter screen 2 is as follows: The center point of the net spreads out in a wave shape, and the wave shape has at least three crests.

[0013] The direction of each mesh of the filter screen is the normal direction of the curve at the position of the mesh;

[0014] The mesh of the filter screen is a regular hexagonal structure;

[0015] The wave shape is a cosine curve;

[0016] The filter mesh structure is processed by 3D printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com