Device and method for adjusting flue-gas temperature at outlet of four-compartment air preheater

A technology of air preheater and flue gas temperature, which is applied in the field of coal-fired boilers, can solve problems such as damage, uneven temperature, and damaged life, so as to improve safety and economy, reduce the impact of equipment life, and smoke The effect of uniform air temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

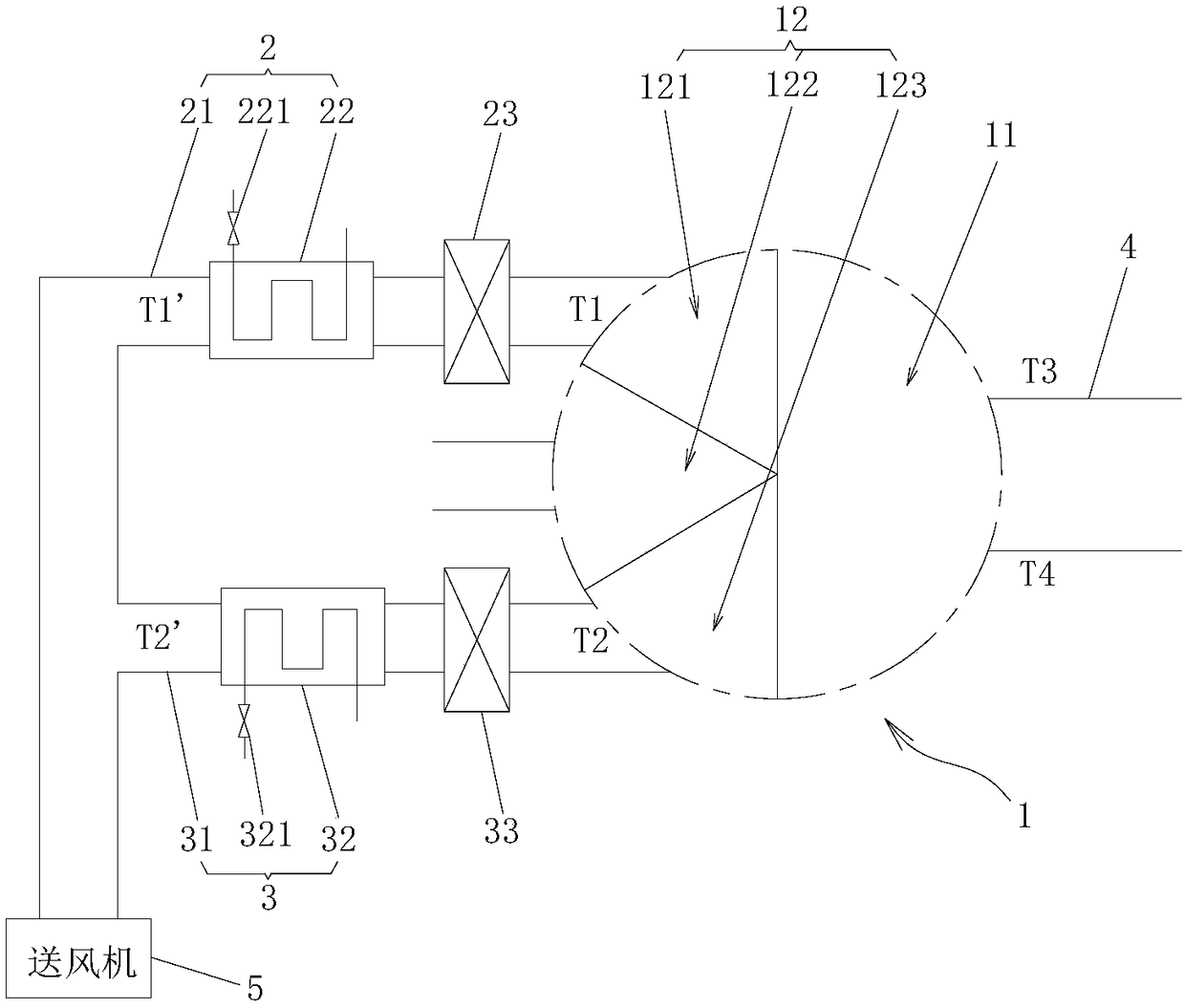

[0032] Such as figure 1 As shown, the present invention provides a device for adjusting the flue gas temperature at the outlet of the four-division air preheater. Channel 11 and cold air channel 12, the cold air channel 12 has a left secondary air channel 121, a primary air channel 122 and a right secondary air channel 123 arranged at intervals in sequence, and the outlet flue gas temperature of the air preheater of the four compartments is adjusted The device is installed on the flue gas duct 1, which includes:

[0033] The first temperature adjustment mechanism 2 has a first pipeline 21 and a first heater 22 connected to the first pipeline 21, and the first heater 22 communicates with the first pipeline 21 through the first pipeline 21. The left secondary air duct 121 is connected;

[0034] The second temperature adjustment mechanism 3 has a second pipeline 31 and a second heater 32 connected to the second pipeline 31, and the second heater 32 communicates with the second ...

Embodiment approach 2

[0050] Such as figure 1 As shown, the present invention also provides a method for adjusting the flue gas temperature at the outlet of the air preheater in the four compartments, which adopts the device for adjusting the flue gas temperature at the outlet of the air preheater in the quarter compartments described in Embodiment 1. The structure, working principle and beneficial effects of the device are the same as those in the first embodiment, and will not be repeated here. The method includes the following steps:

[0051] Step S1: adjusting the air volume Q1 of the first cold air passing into the left secondary air duct 121 and the air volume Q2 of the second cold air entering the right secondary air duct 123;

[0052] Step S2: According to the temperature difference between the two sides of the smoke exhaust passage 4, respectively adjust the temperature T1 of the first cold air passing into the left secondary air duct 121 and the temperature T1 of the second cold air passi...

Embodiment approach 3

[0061] Such as figure 1 As shown, the present invention also provides a method for adjusting the flue gas temperature at the outlet of the air preheater in the four compartments, which adopts the device for adjusting the flue gas temperature at the outlet of the air preheater in the quarter compartments described in Embodiment 1. The structure, working principle and beneficial effects of the device are the same as those in the first embodiment, and will not be repeated here. The method includes the following steps:

[0062] Step S3: Adjust the temperature T1 of the first cold air passing into the left secondary air passage 121 and the temperature T2 of the second cold air passing into the right secondary air passage 123, so that The temperature T1 of the first cold air in 121 is the same as the temperature T2 of the second cold air passing into the right secondary air duct 123;

[0063] Step S4: According to the temperature difference between the two sides of the smoke exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com