Heating start control method and device

A technology for regulating system and wind speed, applied in the field of heating start control method and device, can solve problems affecting user comfort experience, system pressure fluctuation, damage to temperature regulation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

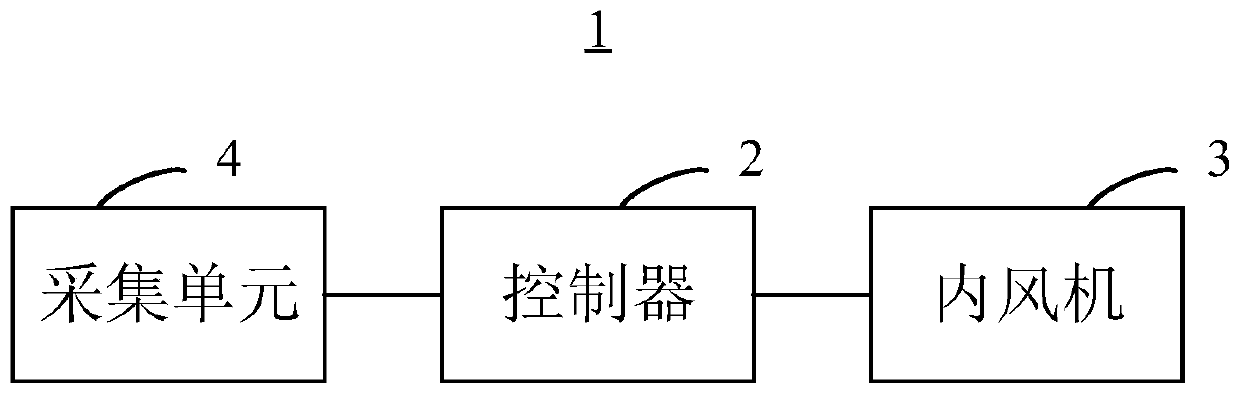

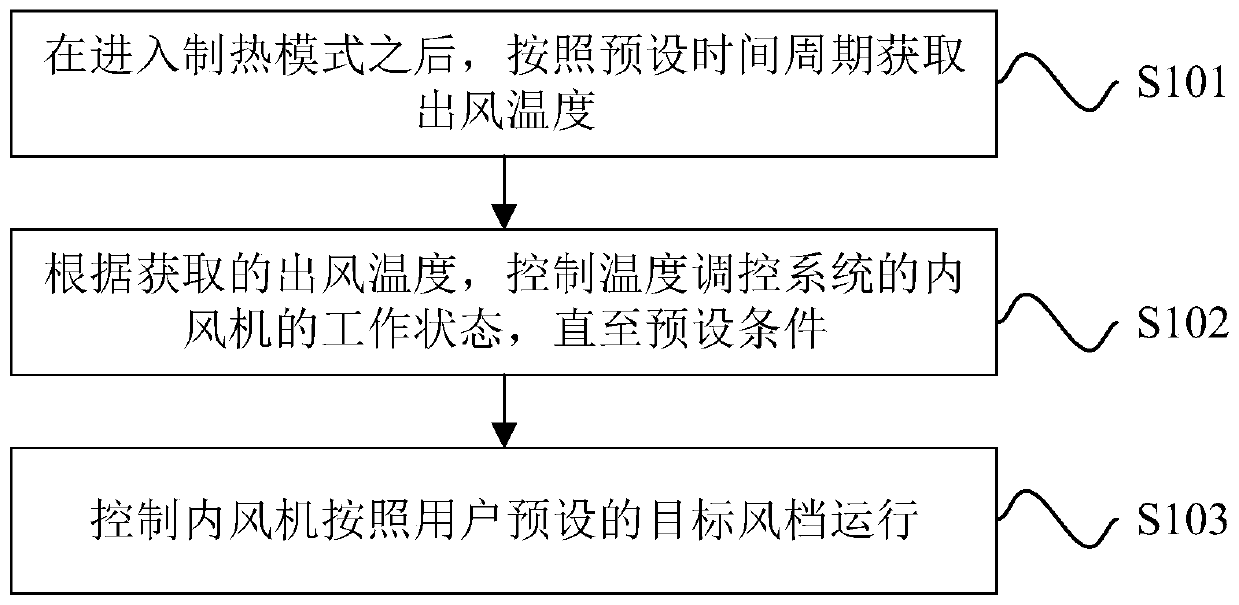

[0038] Please refer to figure 2 , figure 2 It is a flow chart of steps of a heating start control method provided by an embodiment of the present invention. The above heating start control method is applied to the temperature regulation system 1 . The above heating start control method may include the following steps:

[0039] Step S101, after entering the heating mode, the outlet air temperature is acquired according to a preset time period.

[0040] In the embodiment of the present invention, the above-mentioned temperature control system 1 enters the heating mode after starting the heating and exiting the anti-cold wind mode.

[0041] As an implementation, for the temperature control system 1 with the anti-cold wind mode, after starting the heating, it enters the anti-cold wind mode. After the temperature control system 1 exits the anti-cold wind mode, the acquisition unit 4 is used to acquire the outlet air temperature according to a preset time period. Optionally, ...

no. 2 example

[0084] Please refer to Figure 5 , Figure 5 A schematic diagram of a heating start control device 5 provided by an embodiment of the present invention is shown. The above-mentioned heating start control device 5 is applied to such as figure 1 The temperature regulation system 1 is shown. The heating start control device 5 may include:

[0085] The acquiring module 6 is configured to acquire the outlet air temperature according to a preset time period after entering the heating mode.

[0086] Preferably, the above-mentioned temperature regulation system 1 enters the heating mode after heating is started and the temperature regulation system 1 exits the anti-cold wind mode.

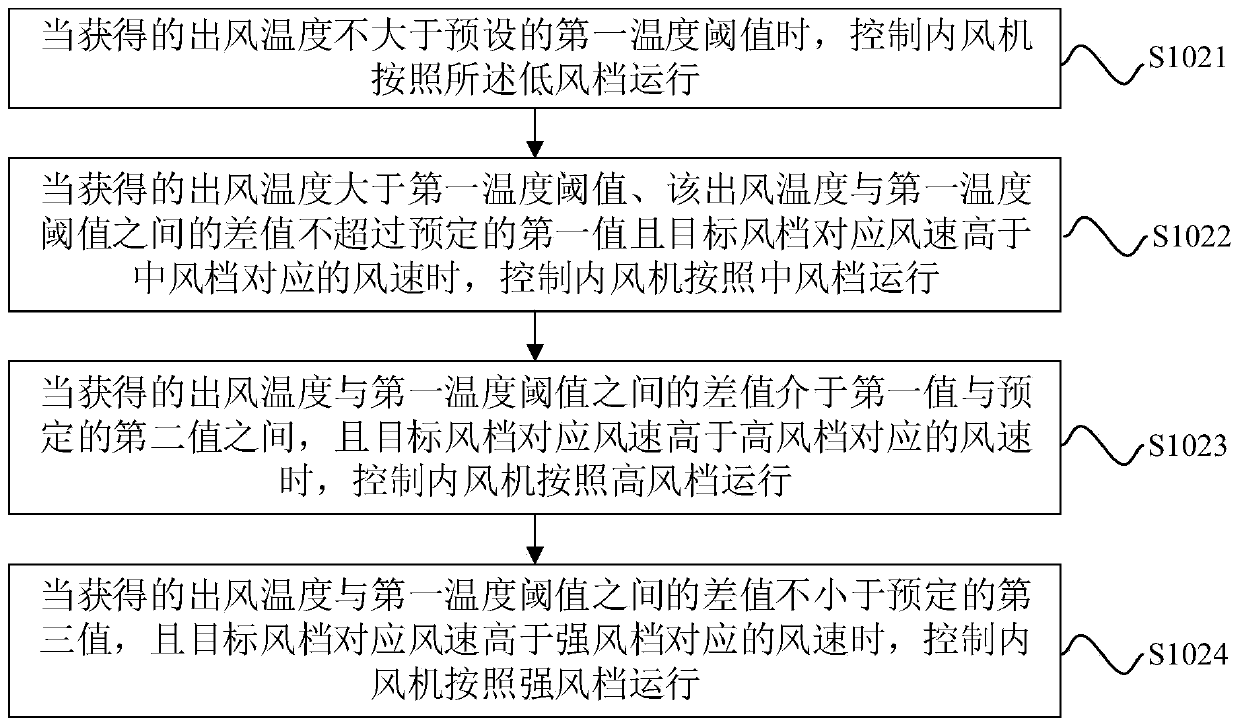

[0087] The windshield adjustment module 7 is configured to control the working state of the internal fan 3 of the temperature control system 1 according to the obtained outlet air temperature until a preset condition is reached.

[0088] The windshield adjustment module 7 is also used to control the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com