Rubber air drying support with improved structure

A drying rack and rubber technology, applied in the direction of static material dryers, local mixing dryers, dryers, etc., can solve the problems of large space occupation, complicated operation, lack of mobility, etc., and achieve simple structure and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

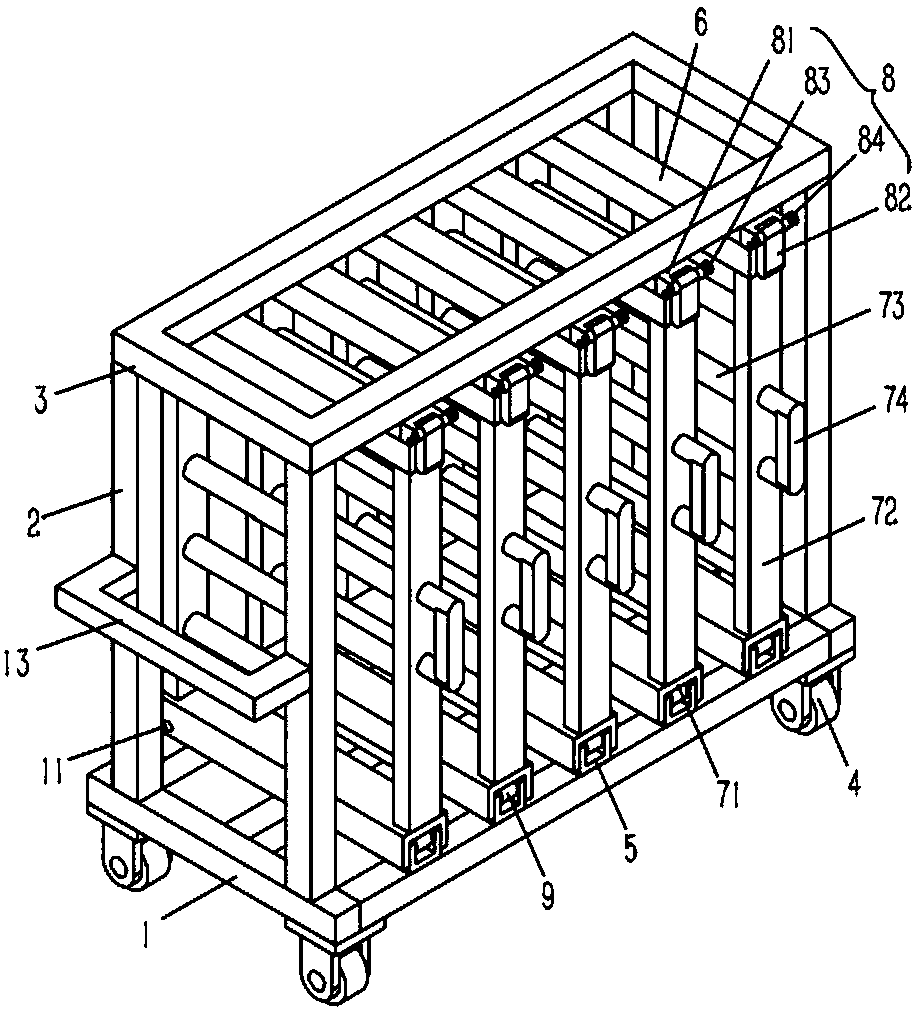

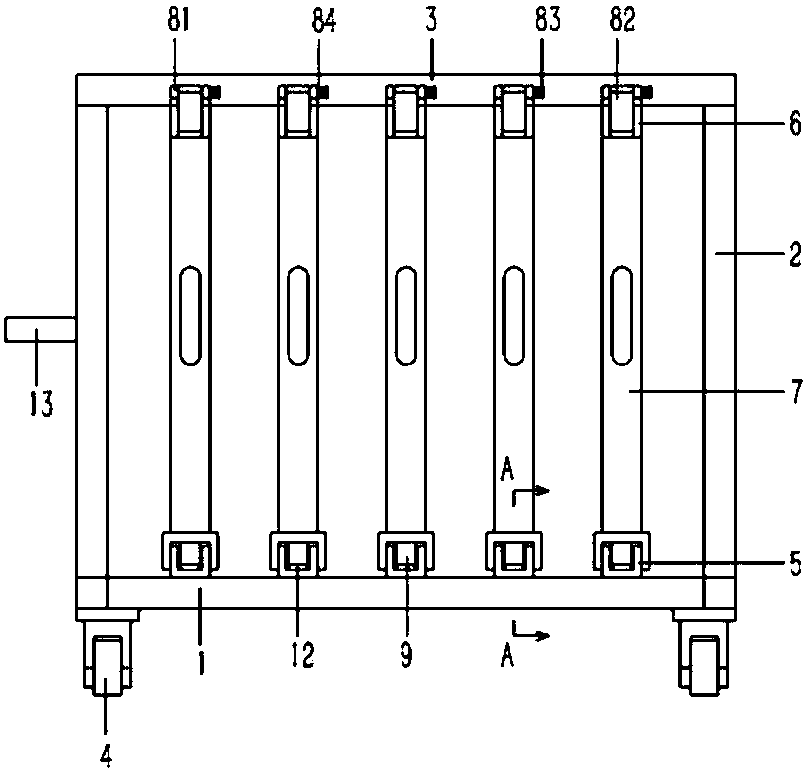

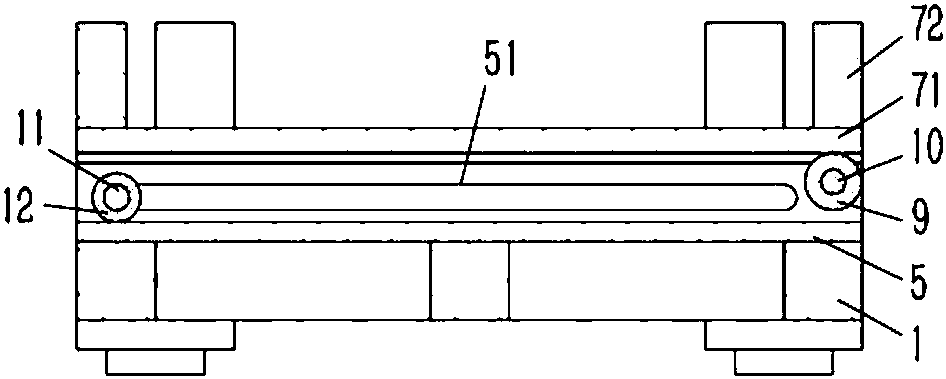

[0015] Example: see Figures 1 to 3 As shown, a rubber drying stand with improved structure includes a rectangular lower frame 1 and an upper frame 3. Several columns 2 are fixed at both ends of the lower frame 1, and the upper ends of the columns 2 are fixed on the upper frame 3. The lower frame 1 The four corners are fixedly connected with wheels 4, and the lower frame 1 is fixed with several "凵"-shaped lower groove rails 5, and the upper frame 3 is fixed with a "冂"-shaped upper groove rail 6 opposite to the lower groove rail 5, and the lower groove A guide groove 51 is formed on both side plates of the rail 5, and a front roller 9 is inserted in the lower groove rail 5 at the front end of the guide groove 51. The front roller 9 is hinged on the front support shaft 10, and the two ends of the front support shaft 10 are plugged It is fixed on the two side walls of the lower groove rail 5; a drying rack 7 is arranged between the upper groove rail 6 and the lower groove rail 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com