Fluid transparency detection device and detection method

A detection device and transparency technology, which is applied in the direction of measuring device, transmittance measurement, scattering characteristic measurement, etc., can solve the problems of inaccurate acquisition of total light intensity, influence on the accuracy of fluid transparency, and single acquisition method of scattered light, so as to improve Detection precision and accuracy, improvement of detection accuracy, and improvement of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 (a kind of fluid transparency detection device)

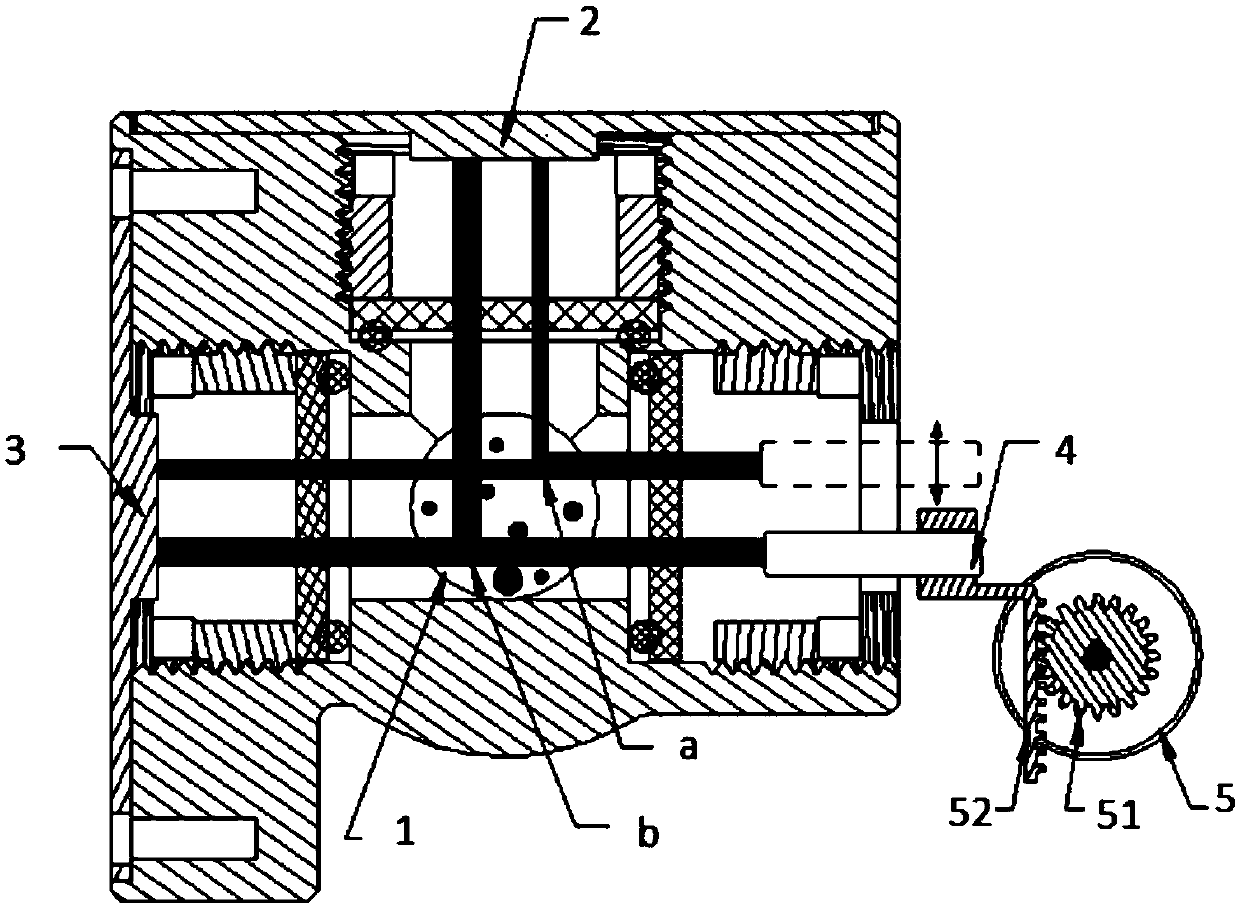

[0058] like figure 1 Shown is a schematic structural diagram of a more preferred embodiment of the fluid transparency detection device of the present invention, which includes: a detection pipeline 1, which allows the light beam to realize the incident and exit of the fluid in the tube; a laser tube 4, used to output the incident light beam ; The photodetector is used to detect the fluid exit beam.

[0059] The photodetector includes: a scattering detector 2, which is used to detect a scattered light beam; a transmission detector 3, which is used to detect a transmitted light beam; The three points of the detector, the detection pipeline, and the laser tube form a right-angle shape; the setting position of the transmission detector is on the same line as the output beam of the laser tube, and the detection pipeline is arranged between the transmission detector and the laser tube. between the laser tubes. ...

Embodiment 2

[0069] Embodiment 2 (a kind of fluid transparency detection method)

Embodiment approach

[0070] This embodiment is the first preferred embodiment of a method for detecting fluid transparency using the above-mentioned device provided by the present invention, and the method includes the following steps:

[0071] S1: Put pure fluid into the device, obtain the scattering noise floor and transmission noise floor of the equipment, and convert it into the corresponding scattered light intensity noise floor I 散射底噪 and transmitted light intensity noise floor value I 透射底噪 ;

[0072] S2: Put the fluid to be tested into the device, the laser tube outputs the laser beam, and then obtain the scattered light and transmitted light voltage signals obtained by the scattering detector and the transmission detector respectively, and convert the scattered light obtained by the scattering detector Strong I 散射 , the transmitted light intensity I obtained by the scattering detector 透射 , and get the absorbed light intensity I of the particles 吸收 ;

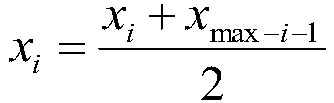

[0073] S3: According to the resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com