Skid-mounted quickly-assembled desulfurization and denitrification flue gas purification device

A technology for desulfurization, denitrification, and flue gas purification, which is applied in the field of flue gas purification, and can solve problems such as difficult discharge of gun smoke and inability to purify in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

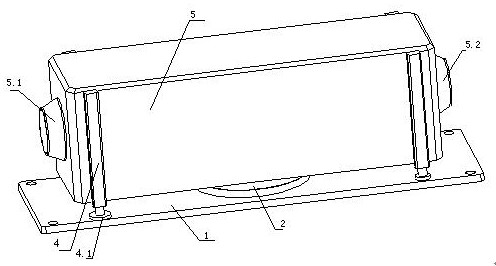

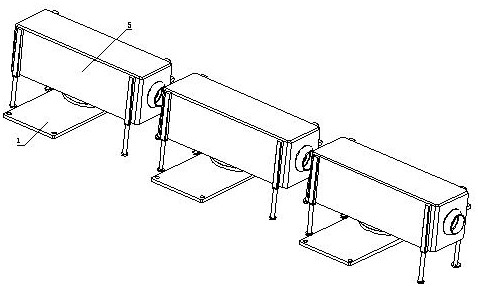

[0028] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0029] A skid-mounted quick assembly desulfurization and denitrification flue gas purification device, including a flue gas treatment cabin 5, a base plate 1, and a rotating mechanism, the flue gas treatment cabin is fixed on the rotating mechanism, and the rotating mechanism is fixed on the base plate superior.

[0030] Further, the rotating mechanism is a turntable 2, and a motor and a transmission mechanism connected to each other are arranged on the base plate, and the output end of the transmission mechanism is connected to the turntable by transmission.

[0031] Further, the transmission mechanism is a driven gear, the input end of the driven gear is connected to the output end of the motor, and the driven gear meshes with the ring gear of the turntable.

[0032] Further, the flue gas treatment cabin is a washing cabin, an oxidation cabin or an absorption cabin.

[0033] Further,...

Embodiment 2

[0059] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0060] A skid-mounted quick assembly desulfurization and denitrification flue gas purification device, including a flue gas treatment cabin 5, a base plate 1, and a rotating mechanism, the flue gas treatment cabin is fixed on the rotating mechanism, and the rotating mechanism is fixed on the base plate superior.

[0061] Further, the rotating mechanism is a turntable 2, and a motor and a transmission mechanism connected to each other are arranged on the base plate, and the output end of the transmission mechanism is connected to the turntable by transmission.

[0062] Further, the transmission mechanism is a driven gear, the input end of the driven gear is connected to the output end of the motor, and the driven gear meshes with the ring gear of the turntable.

[0063] Further, the flue gas treatment cabin is a washing cabin, an oxidation cabin or an absorption cabin.

[0064] Further,...

Embodiment 3

[0068] see Figure 1 to Figure 2 , the present invention provides a technical solution:

[0069] A skid-mounted quick assembly desulfurization and denitrification flue gas purification device, including a flue gas treatment cabin 5, a base plate 1, and a rotating mechanism, the flue gas treatment cabin is fixed on the rotating mechanism, and the rotating mechanism is fixed on the base plate superior.

[0070] Further, the rotating mechanism is a turntable 2, and a motor and a transmission mechanism connected to each other are arranged on the base plate, and the output end of the transmission mechanism is connected to the turntable by transmission.

[0071] Further, the transmission mechanism is a driven gear, the input end of the driven gear is connected to the output end of the motor, and the driven gear meshes with the ring gear of the turntable.

[0072] Further, the flue gas treatment cabin is a washing cabin, an oxidation cabin or an absorption cabin.

[0073] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com