Heat radiating fin

A technology of heat sinks and peaks, applied in the field of corrugated heat sinks, can solve the problems of rising manufacturing costs, difficulty in processing shutters, and increasing surface area, so as to eliminate heat stagnation, increase surface area, and improve heat dissipation capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

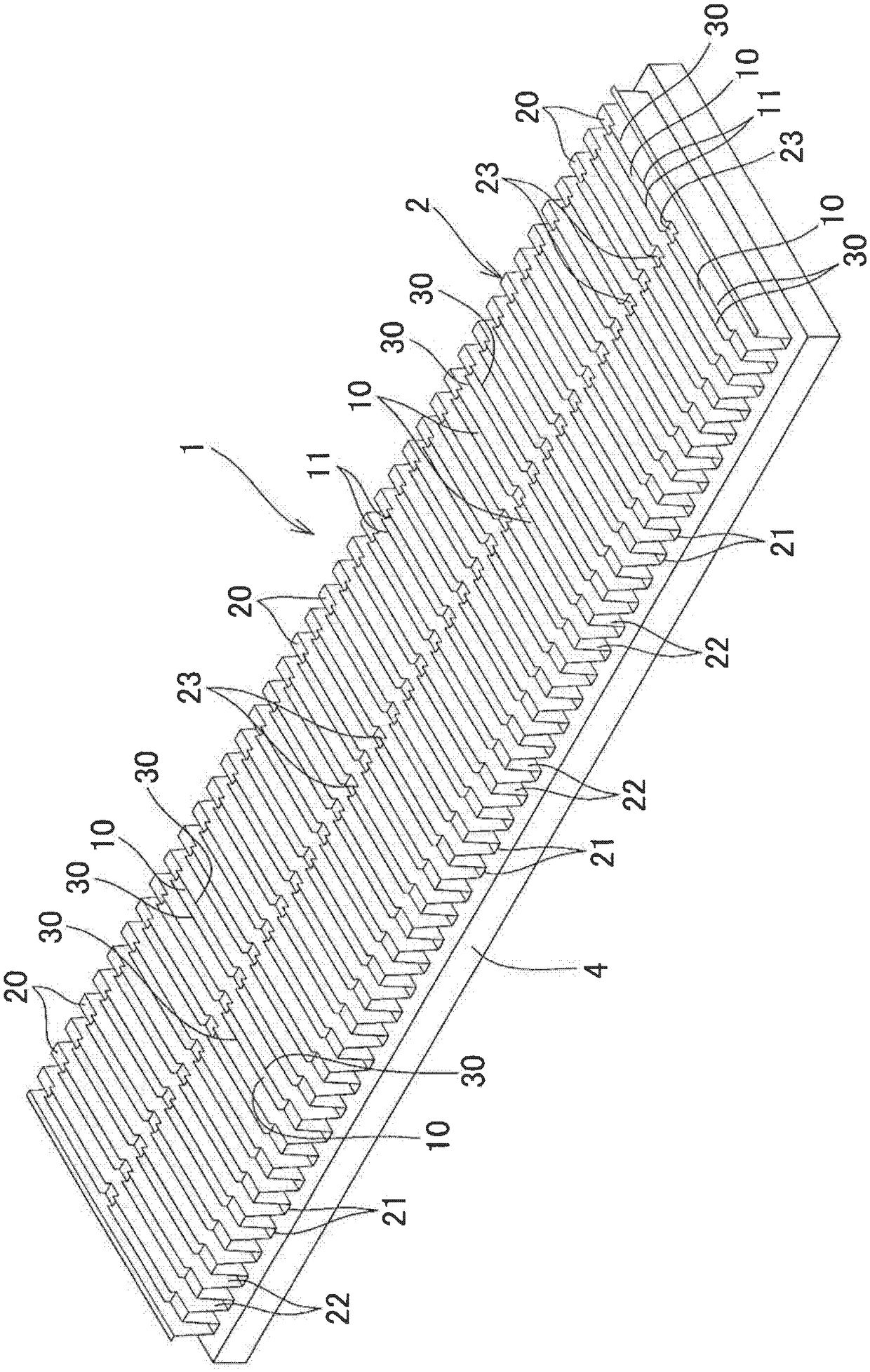

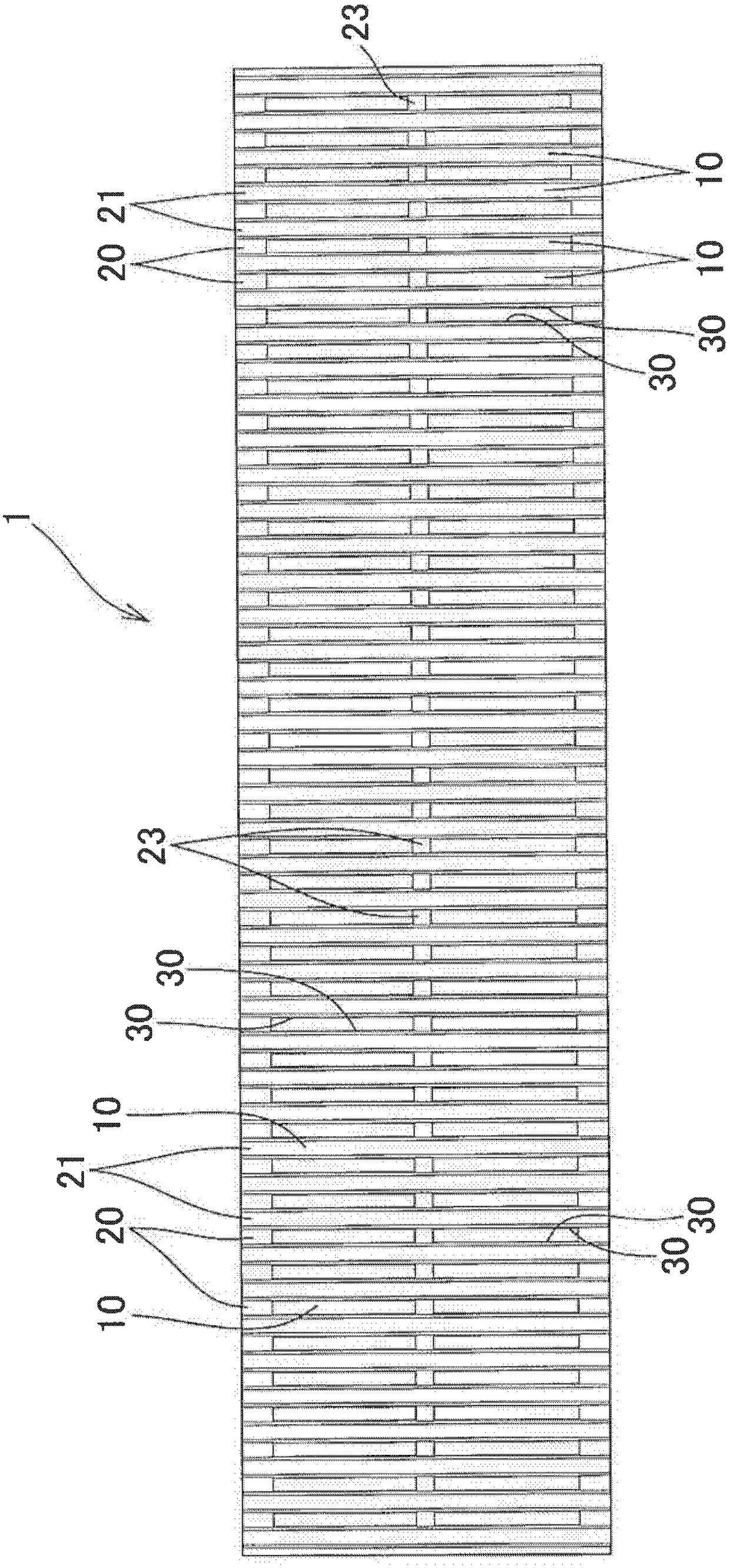

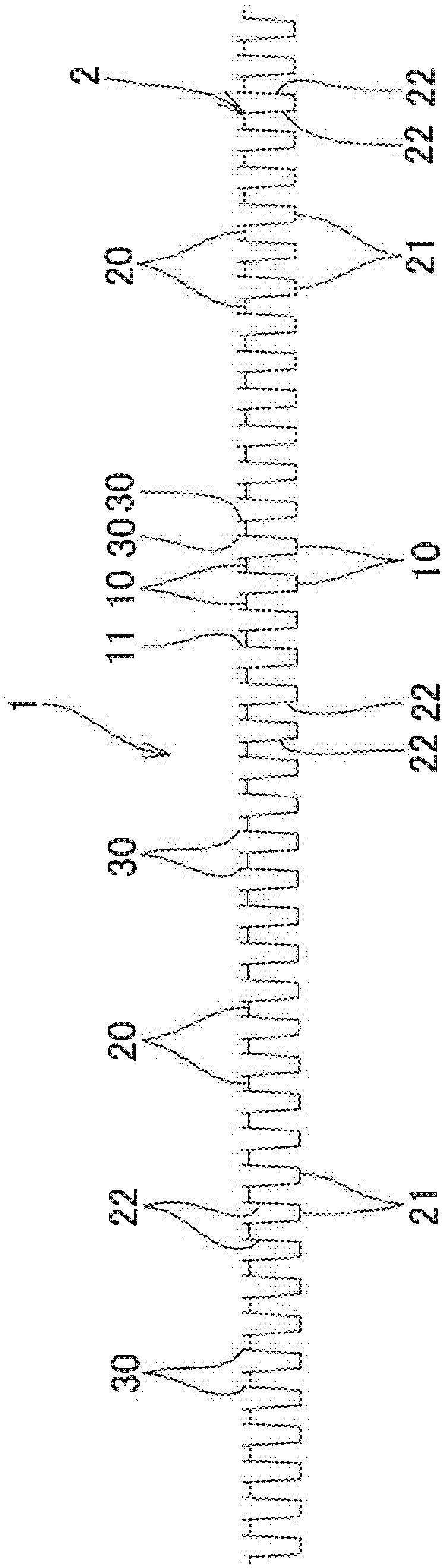

[0048] Next, embodiments of the present invention will be described in detail based on the drawings.

[0049] Such as Figure 1 to Figure 5 As shown, the heat sink 1 of the present invention is provided with through grooves 10 extending in the column direction for passing fluid on the above-mentioned peaks 20 of the metal plate 2 in which a plurality of column-shaped peaks 20 and valleys 21 are alternately formed. , and the opening edge portion 11 of the through groove 10 is provided with a rising piece 30 rising toward the convex side of the peak portion 20, and is installed so that the convex side surface of the valley portion 21 faces the object 4 to be cooled.

[0050] In this embodiment, an example is shown in which the heat sink 1 is attached and used in a state where the convex surface side of the valley portion 21 is directly in contact with the object 4 to be cooled, but it is not limited thereto. For example, although not shown, it may also be configured as A base m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com