Invariant-center-of-gravity optimal-time leveling algorithm

A time-optimized and center-of-gravity technology, applied in the field of leveling algorithms, can solve problems such as less time consumption and difficult platform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

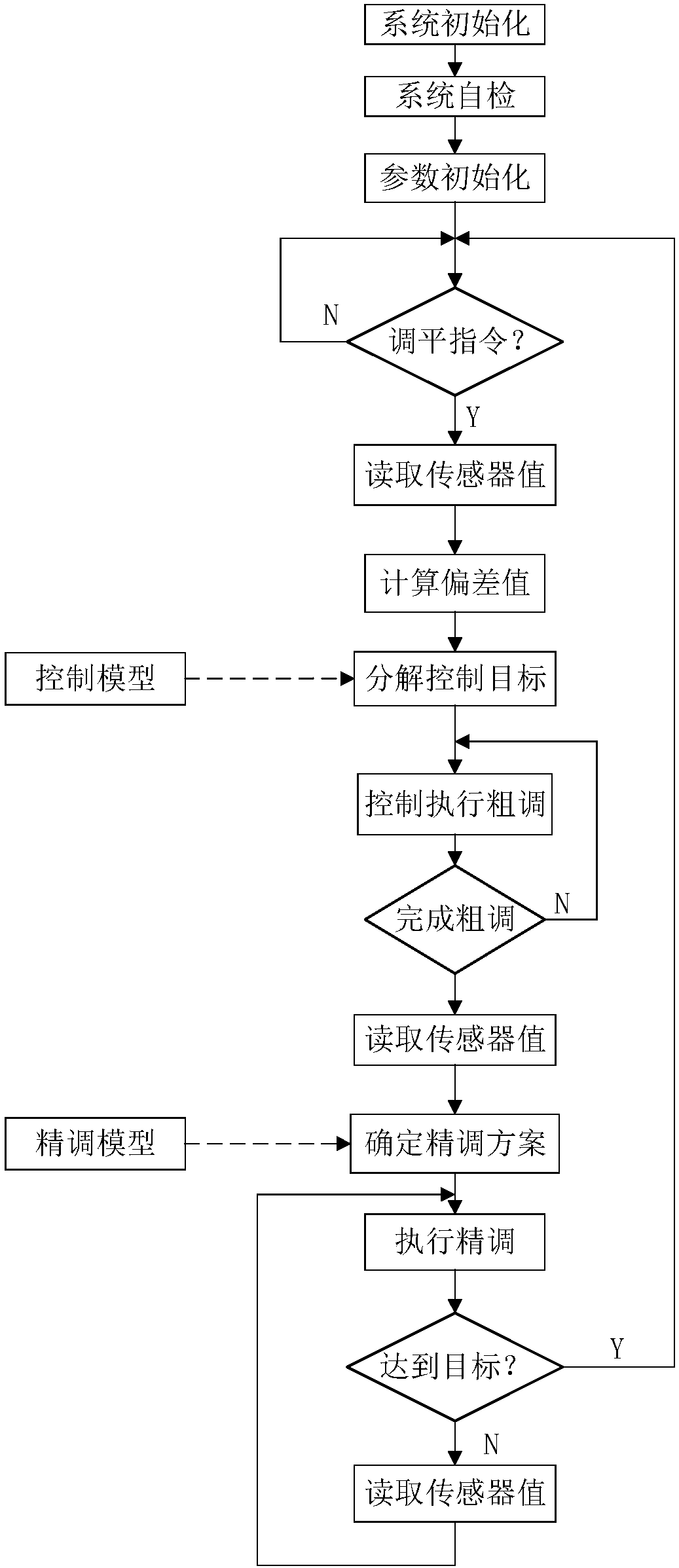

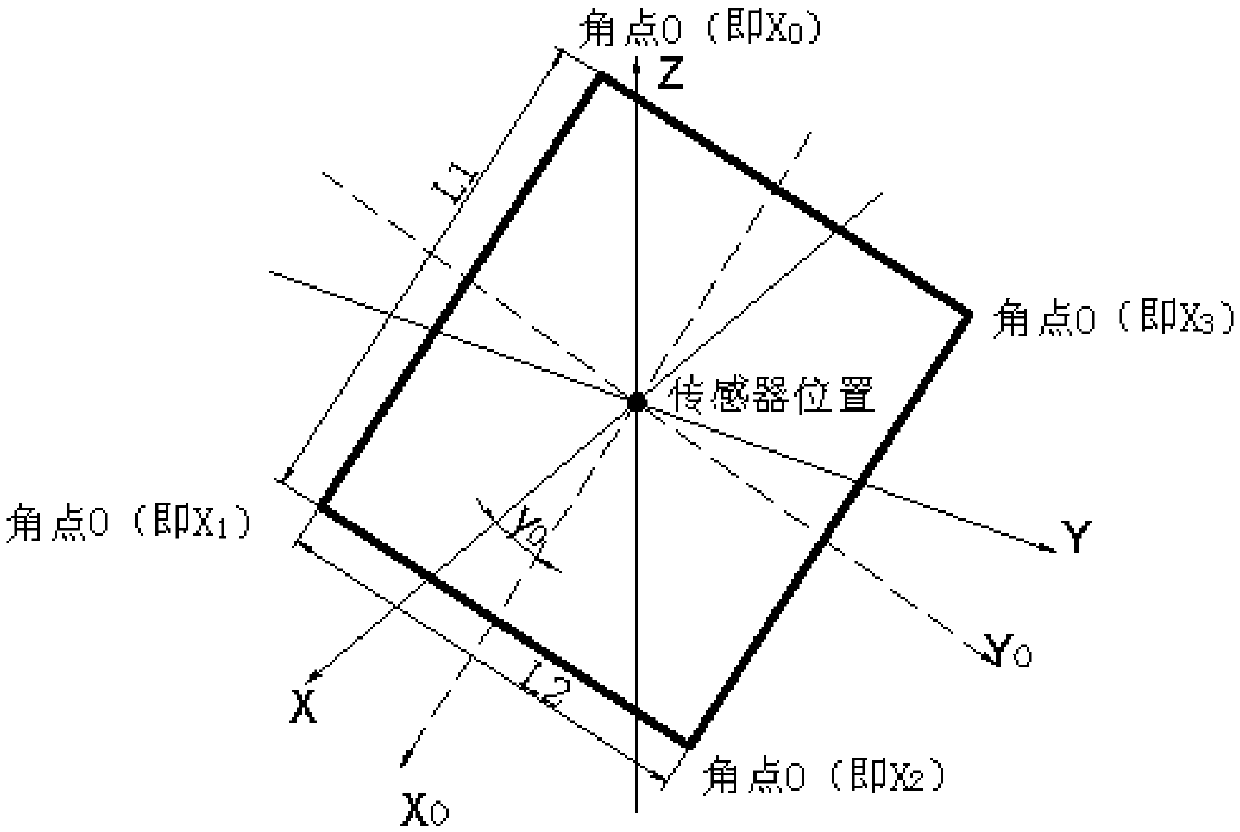

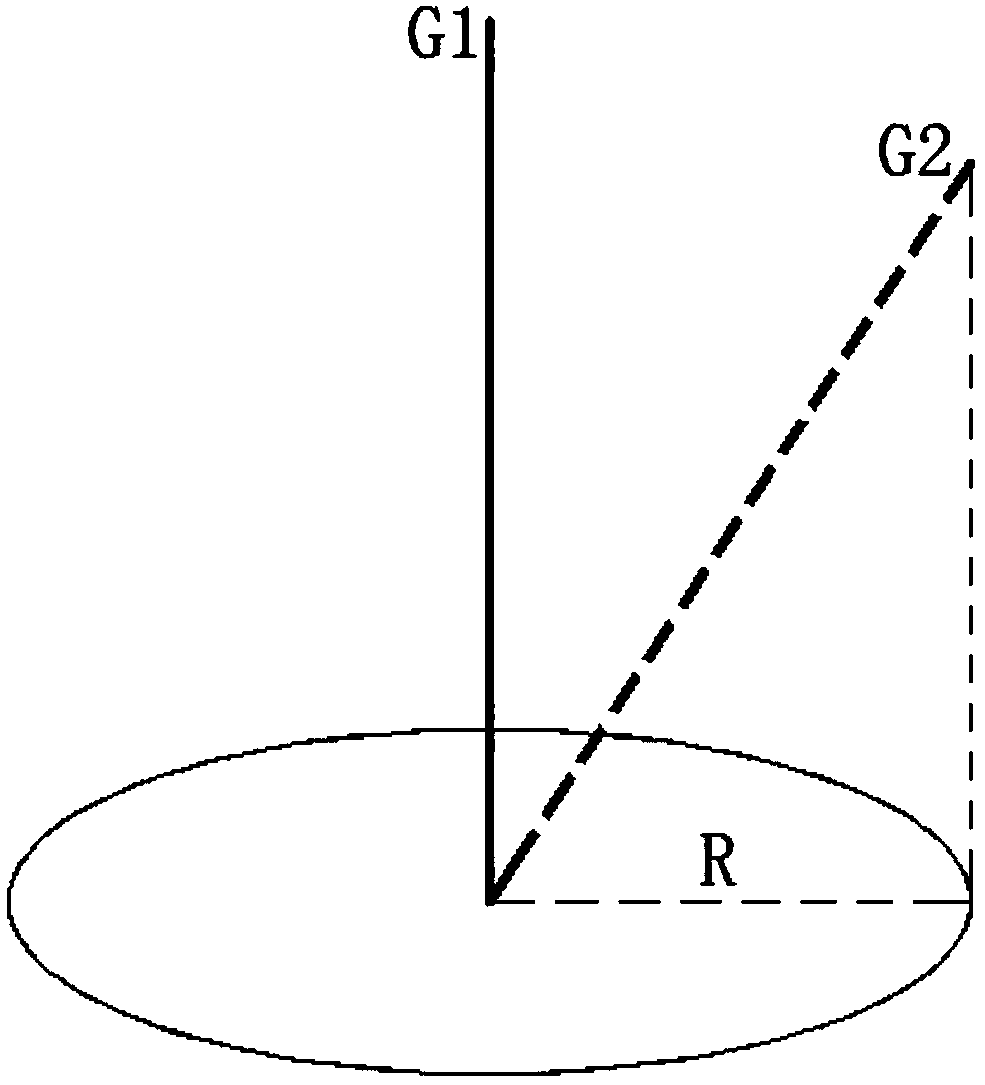

[0051] A time-optimized leveling algorithm with a constant center of gravity, which is a method to maintain the balance of the platform by adjusting the position error between the center of gravity of the platform and its support point, as shown in the attached figure 1 As shown, two rounds of coordinate transformation calculations are carried out for the four fulcrums of the platform: fast rough adjustment and time-optimized fine adjustment. At the same time, the traditional leveling scheme is to first determine the highest point of the four hydraulic outriggers, and then adjust the other three outriggers one by one to make the workbench level. The leveling method adopts the four-axis linkage adjustment method, which can complete the leveling in a short time and significantly improve the leveling efficiency. The algorithm specifically includes the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com