Test stand for testing comprehensive brake property of brake pad of high speed train

A technology for brake pads and high-speed trains, which is applied in the direction of railway vehicle testing, mechanical component testing, machine/structural component testing, etc., and can solve problems such as vibration noise, thermal cracks, uneven wear of friction blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

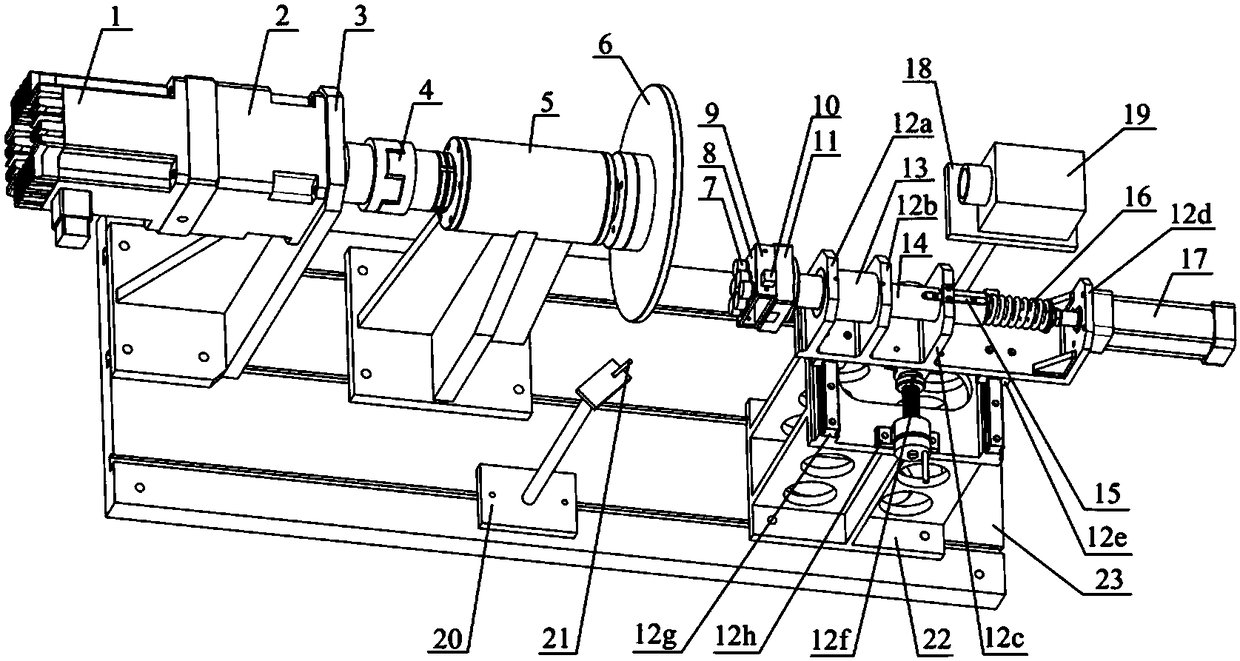

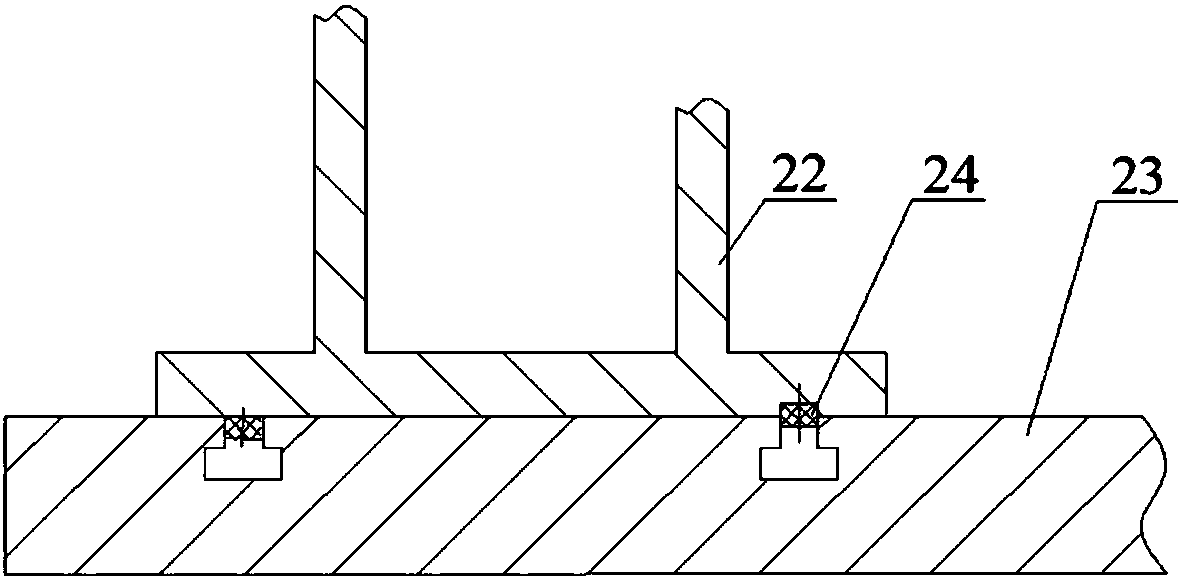

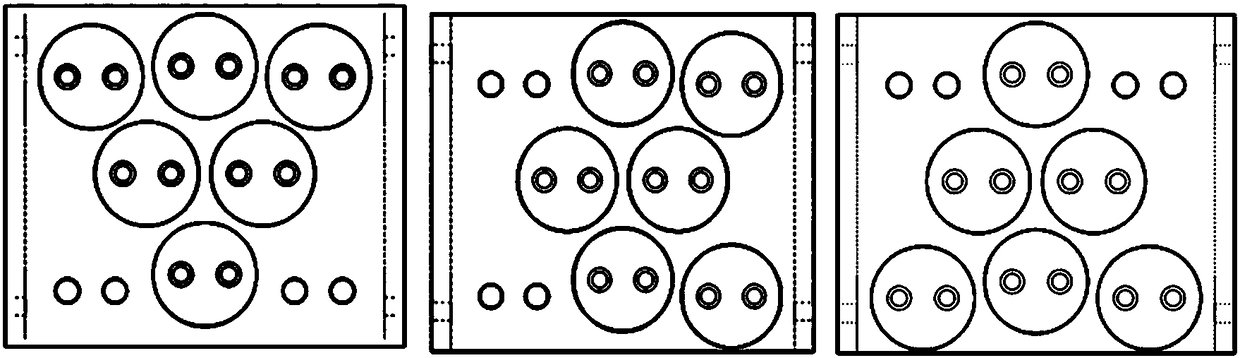

[0030] figure 1The test bench for comprehensive braking performance of the high-speed train brake pads is shown. The servo motor 1 is installed on the support plate 3, and the support plate 3 is arranged on the rectangular base 23. The output shaft of the servo motor arranged horizontally passes through the shaft coupling 4 The outer end of the extended rolling bearing is fixed with a brake disc 6, the rolling bearing is fixed on the base through the rolling bearing seat 5, and the base is arranged on the base 23; T-shaped groove; the bottom plate of the first support seat 22 is movably fixed on the two inverted T-shaped grooves of the base 23 through four bolts, and the left and right sides of the top plate of the first support seat 22 are longitudinally provided with two slide rails 12g , the ball screw 12f is located in the middle of the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com