Cement-based material anti-cracking performance quick testing device with round outside and square inside

A cement-based material and anti-crack performance technology, applied in the direction of measuring devices, analysis materials, material inspection products, etc., can solve the problems of long test period, difficult crack observation, uncertain crack position, etc., to achieve simple measurement and shorten the test process time, effects of increased sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific implementation methods and related drawings.

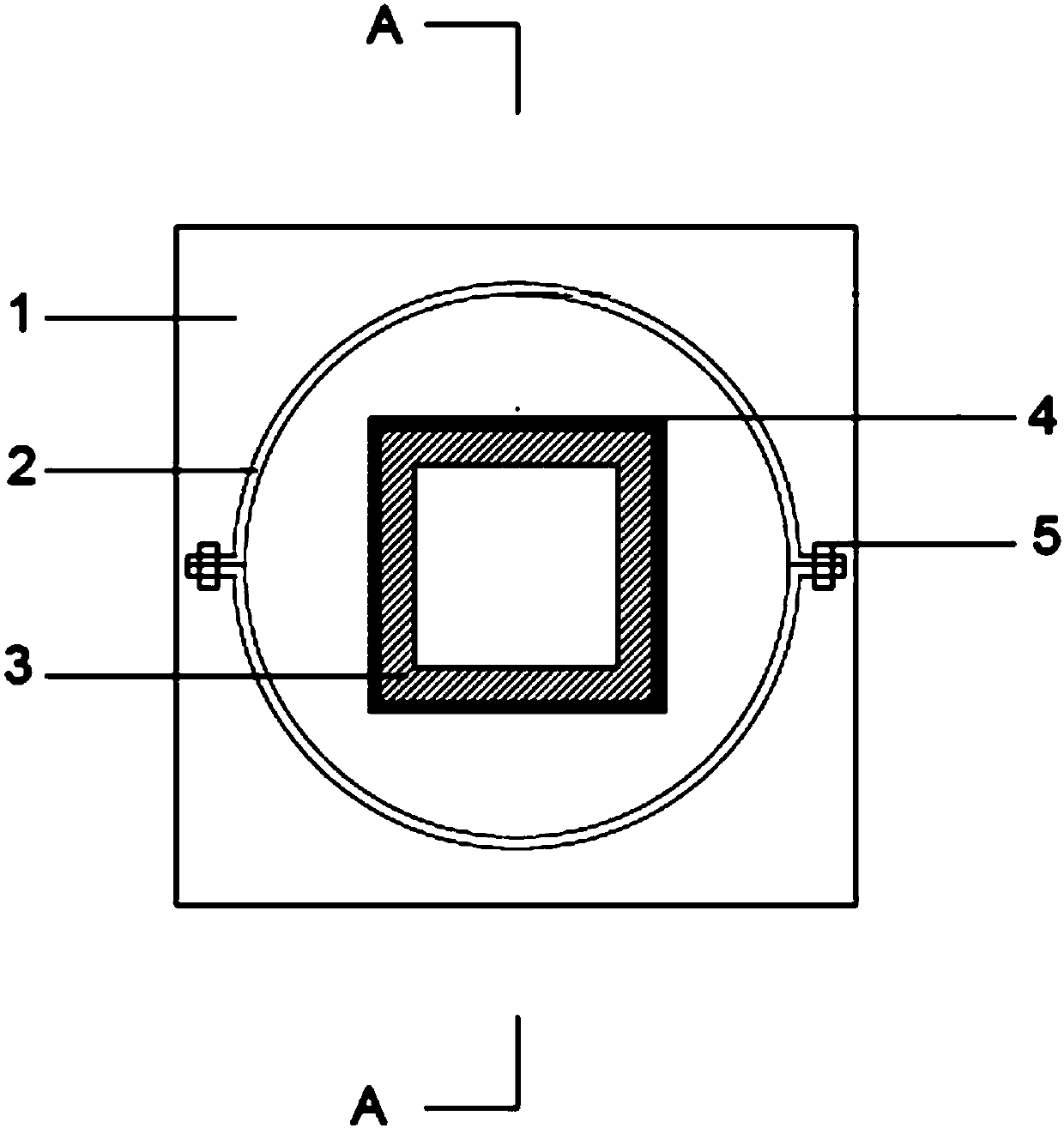

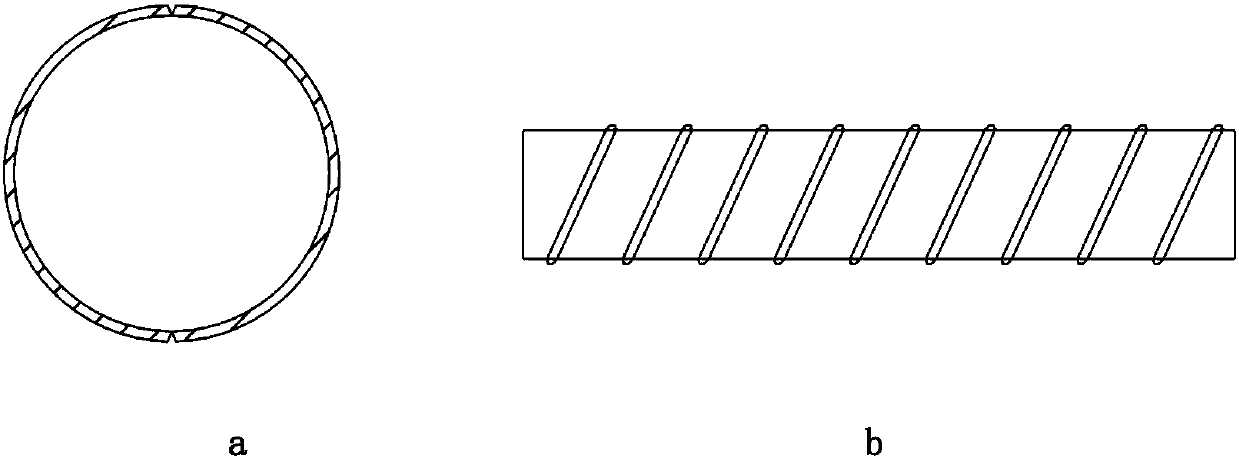

[0025] Such as Figure 1~2 As shown, a quick test device for the crack resistance of cement-based materials with an outer circle and an inner square, including a stepped bottom plate 1, an annular outer formwork, a square inner steel mold 3 and an induced cracking member, the side length of the square inner steel mold 3 is The thickness is 175mm, the thickness is 25mm, and the height is 100mm. The crack-inducing member is composed of two ribbed steel bars 4 . The annular outer formwork is connected at the junction by two semicircular PVC formworks 2 through butt bolts 5. The inner diameter of the semicircular PVC formwork 2 is 330mm and the height is 100mm. The stepped bottom plate 1 is made of steel, and its bottom surface is 400mm 400mm square...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com