Safety check system for underground cavern group

A technology for underground caverns and safety inspections, applied in structured data retrieval, image data processing, instruments, etc., can solve problems such as poor geological conditions, chaotic layout, and many risk factors, so as to improve inspection efficiency, improve management level, Strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

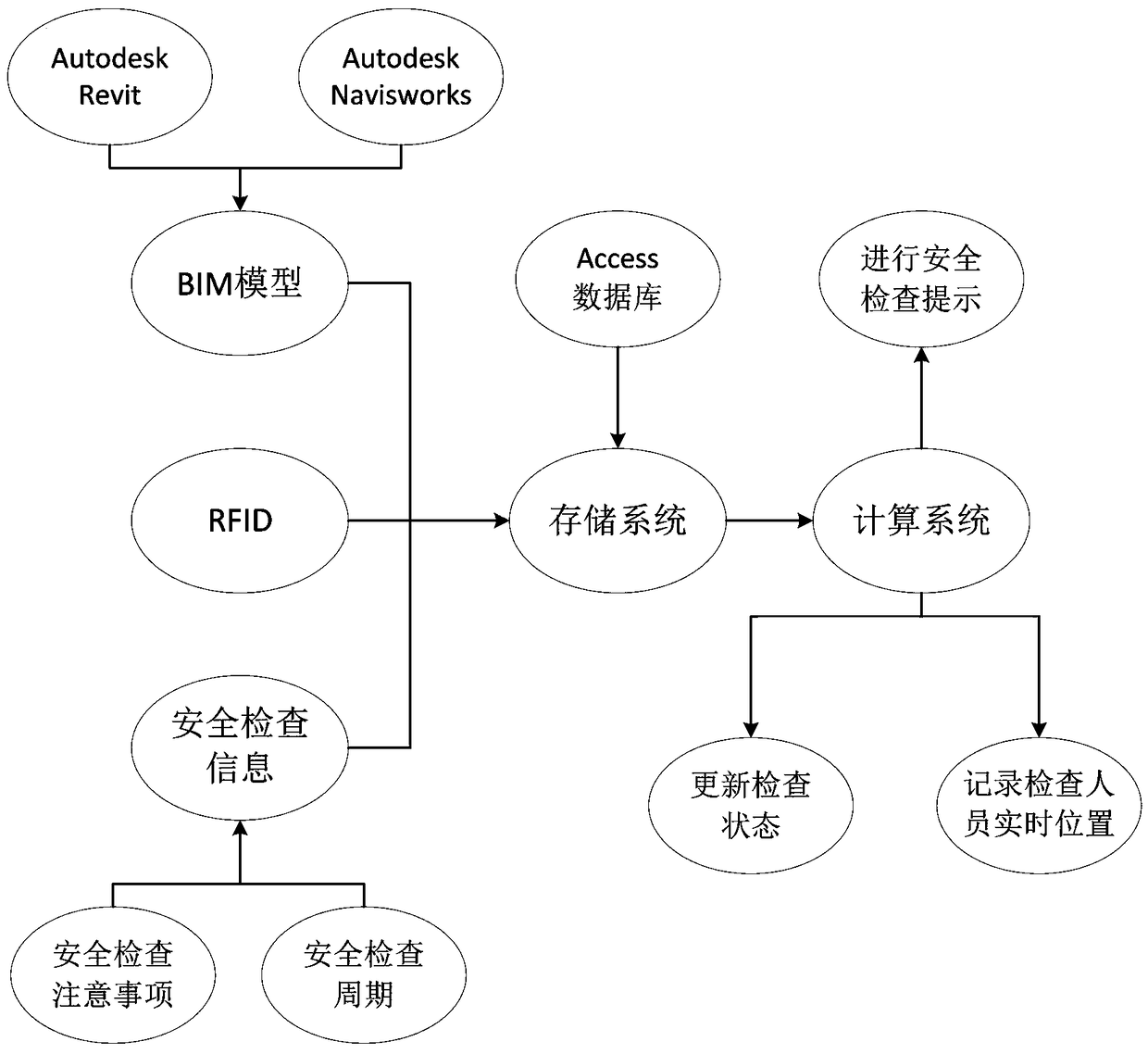

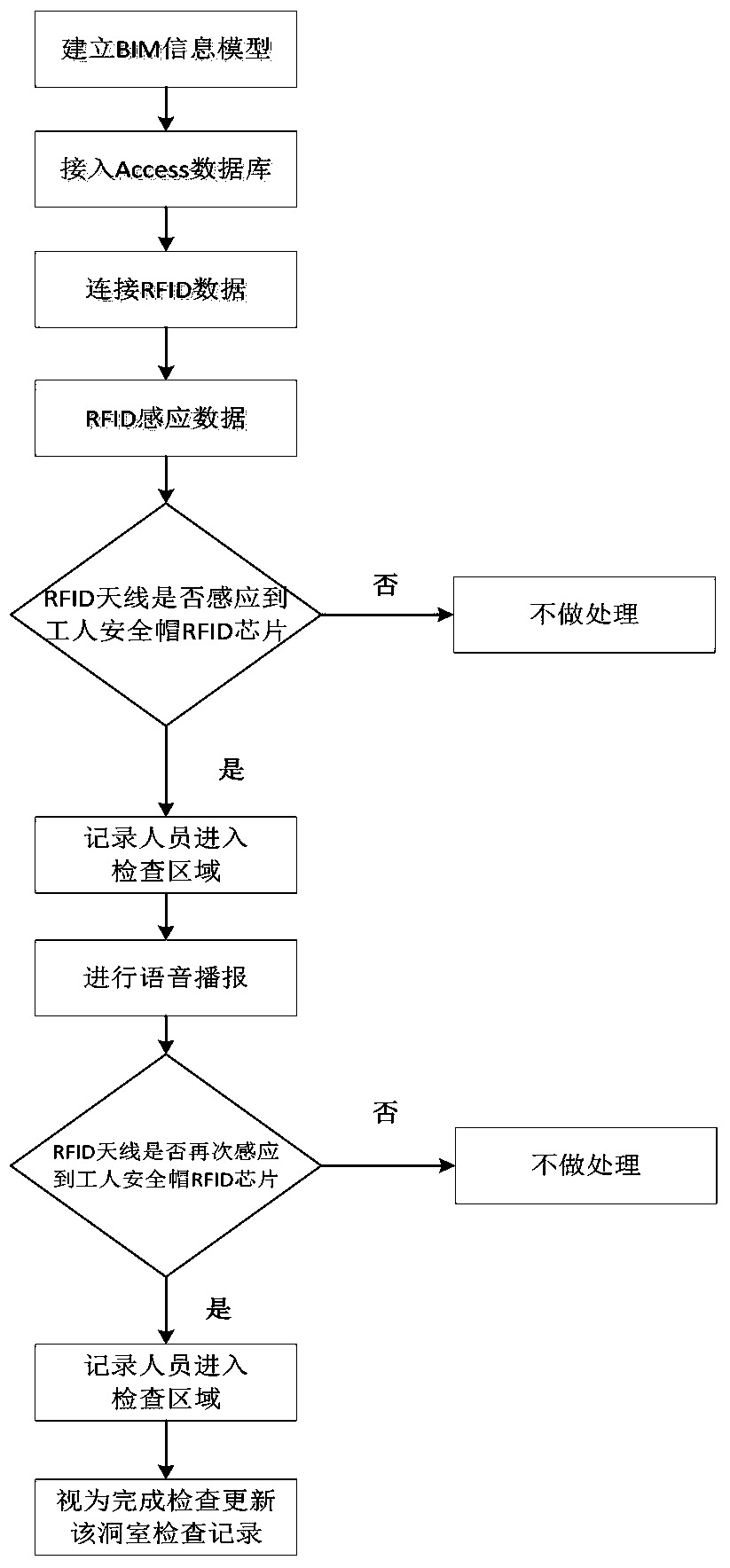

[0031] A security inspection system for underground caverns, comprising the following steps:

[0032] 1) Establish the building and structure model of the underground cavern group, and establish the safety inspection database of the underground cavern group, and the safety inspection database is set in the storage device 2;

[0033] 2) Arrange sensing devices 3 in each underground cavern group, which can sense the staff entering the cavern;

[0034] 3) After sensing that the staff has left, the sensing device updates the inspection status of the underground cavern group in the safety inspection database in the storage;

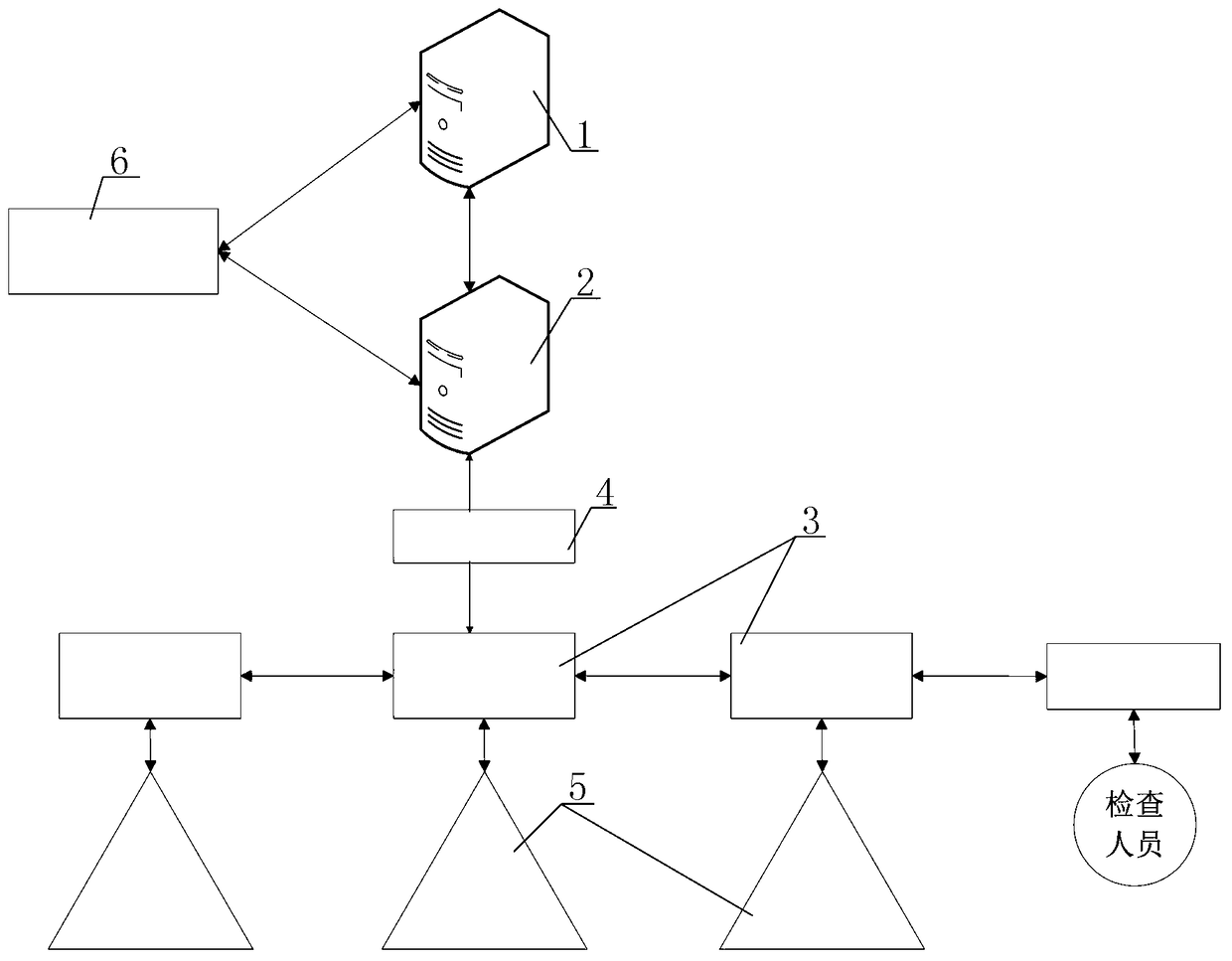

[0035] Including a computer system 1, the first data terminal of the computer system 1 is connected to the storage 2, the storage 2 is provided with a database, and the computer system can access the data of the database in the storage;

[0036] The second data terminal of the computer system 1 is connected to the communication module, which is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com