Arc extinguishing apparatus

A technology of arc extinguishing device and limit device, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of weakened arc extinguishing ability, large volume of arc extinguishing device, high grid temperature, etc., and achieves enhanced arc extinguishing ability and improved The effect of frequent arc extinguishing ability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

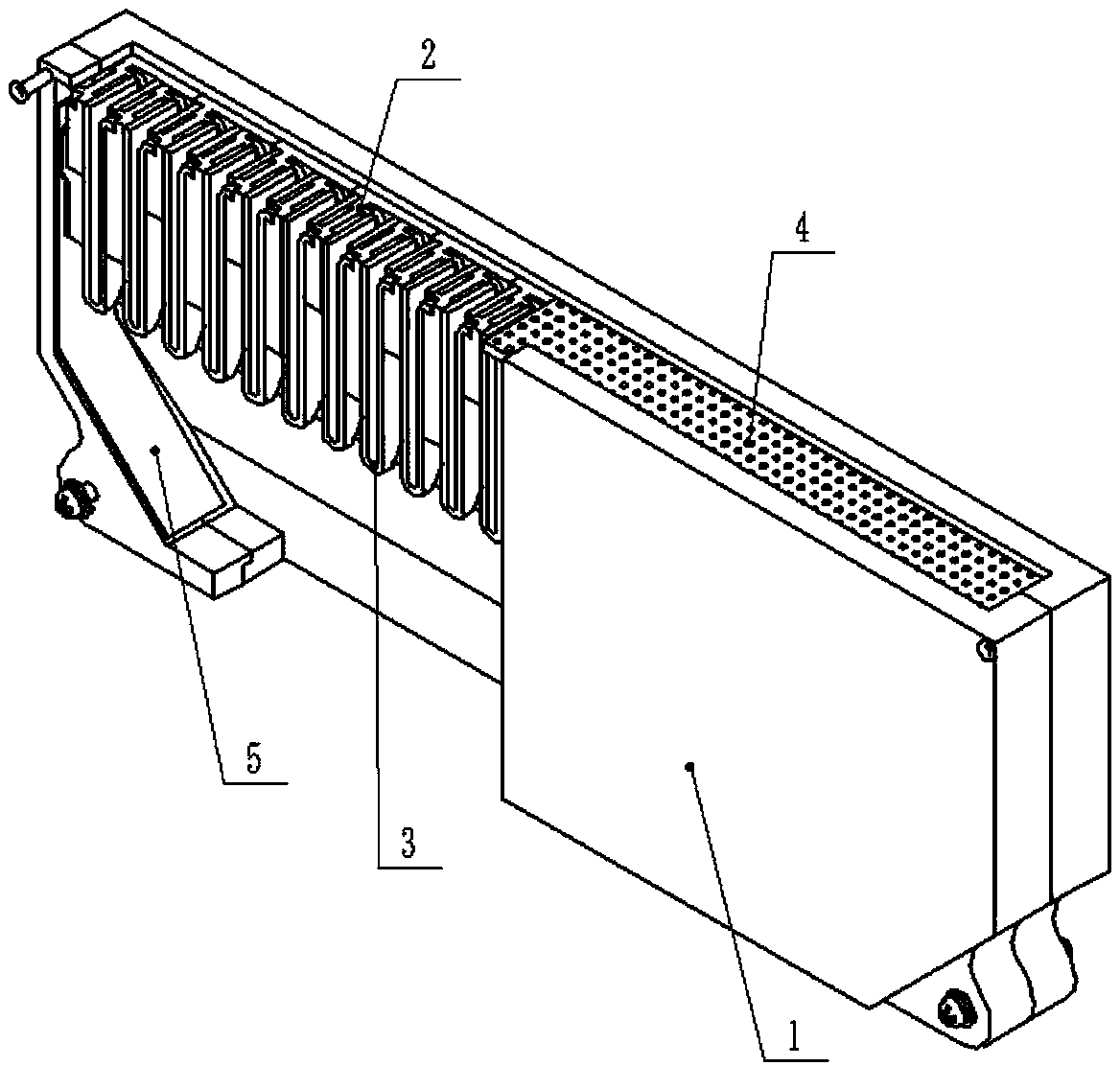

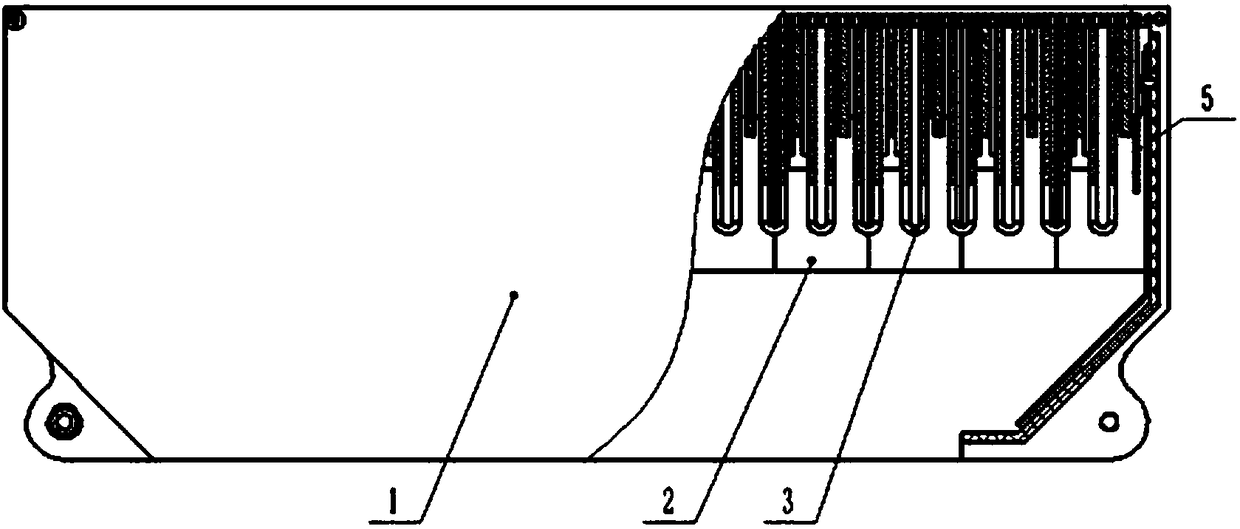

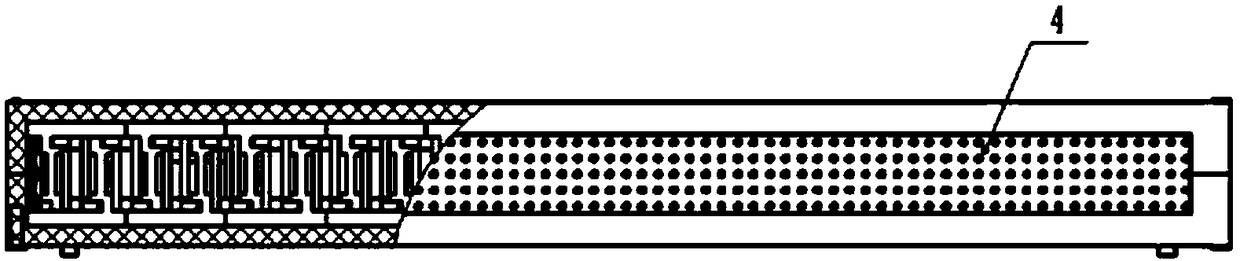

[0033] Such as figure 1 , Figure 2a with Figure 2b As shown, the arc extinguishing device provided by the present invention includes a side plate 1, a grid piece 2 made of an insulating material, a grid piece 2 3 made of a metal material, a protective plate 4 and an arc strike plate assembly 5; the side plate 1 can be For such figure 1 As shown in the shape of a cuboid with an opening on one side, the grid sheet 1 is connected to the inner wall of the side plate 1. The grid sheet 1 includes at least partitions 22 arranged at intervals, and a cavity is formed between two adjacent partitions 22. The grid sheet 2 3 Located in the space formed by the two grid pieces 1, the limit device 32 of the head of the grid piece 2 3 is located in the slot 23 of the grid piece 1 2, the protective plate 4 is located inside the side plate 1, the grid piec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap