Fuel cell flow guiding bipolar plate capable of draining in time and conveniently, and fuel cell system

A fuel cell and bipolar plate technology, used in fuel cells, fuel cell components, circuits, etc., can solve the problems of air waste, increased mechanical power consumption of transporting air or circulating hydrogen, and reducing the efficiency of fuel cell systems. The effect of improving lifespan and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

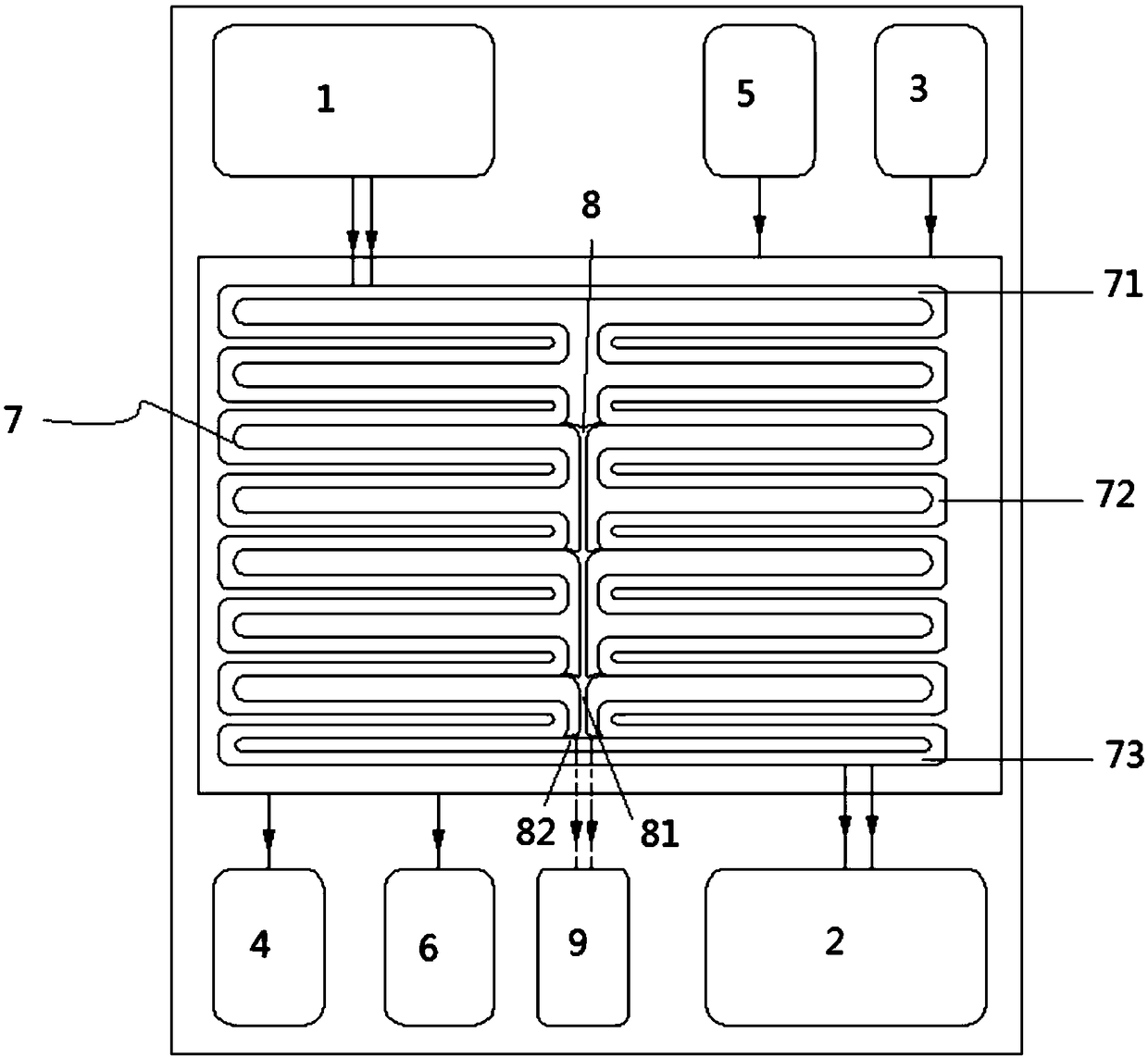

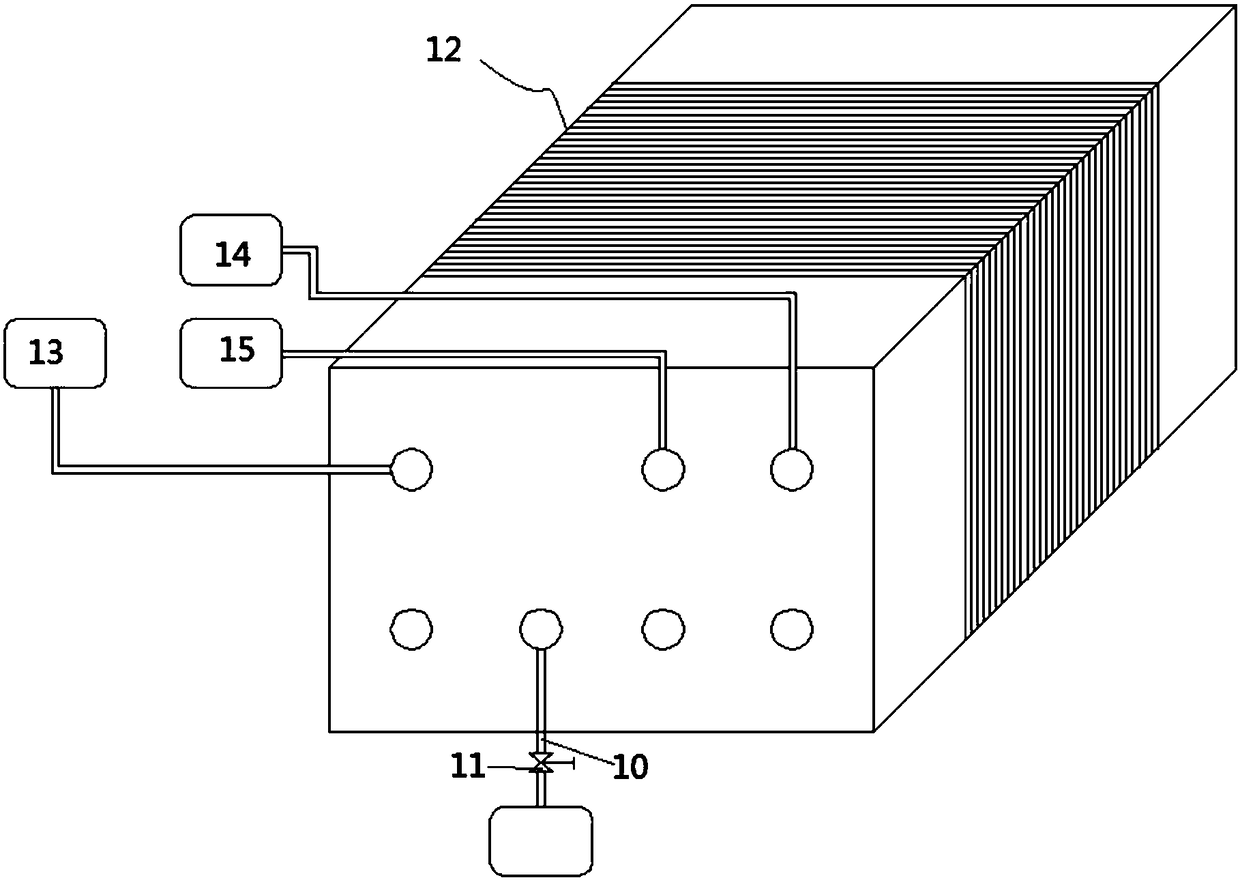

[0029] Such as figure 1 As shown, the fuel cell flow deflector with timely and convenient drainage is composed of a front air guide flow channel plate, a reverse hydrogen guide air flow channel plate, and a middle cooling fluid interlayer. The front air guide flow channel plate is provided with an oxidant inlet 1 and an oxidant Outlet 2, the oxidizer inlet 1, oxidizer outlet 2, fuel inlet 3, fuel outlet 4, cooling fluid inlet 5, cooling fluid outlet 6, oxidizer inlet 1 and oxidizer outlet 2 are connected through oxidant diversion groove 7, oxidant diversion The structure of the groove 7 includes a drainage groove 71 at the entrance, two sets of curved serpentine flow channels 72 arranged side by side in the middle, a confluence groove 73 at the outlet at the bottom, and a drainage channel 8 arranged between the two groups of curved serpentine flow channels 72 The drainage channel 8 includes a straight-flow groove 81 and a plurality of branch grooves 82 arranged on both sides t...

Embodiment 2

[0034] Drainage channels are set on the front air-guiding flow channel plate, and the reverse hydrogen-conducting air flow channel plate is a traditional plate structure without drainage channels. All the other are with embodiment 1.

Embodiment 3

[0036] The length of the straight-flow groove 81 is 1 / 2 of the length of the flow field formed by the oxidant flow diversion groove 7, the width of the straight-flow groove 81 is 1 / 10 of the width of the oxidant flow diversion groove 7, and the width of the branch flow groove 82 is 1 / 10 of the width of the oxidant flow diversion groove 1 / 20 of the width of 7. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com