Ore impurity precipitation machine

A technology of impurity precipitation and settler, which is used in precipitation separation, control of the inclination of precipitation equipment, sedimentation tank, etc., can solve the problems of difficult ore pulp and impurity shutdown, avoid material accumulation problems, ensure continuity, and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

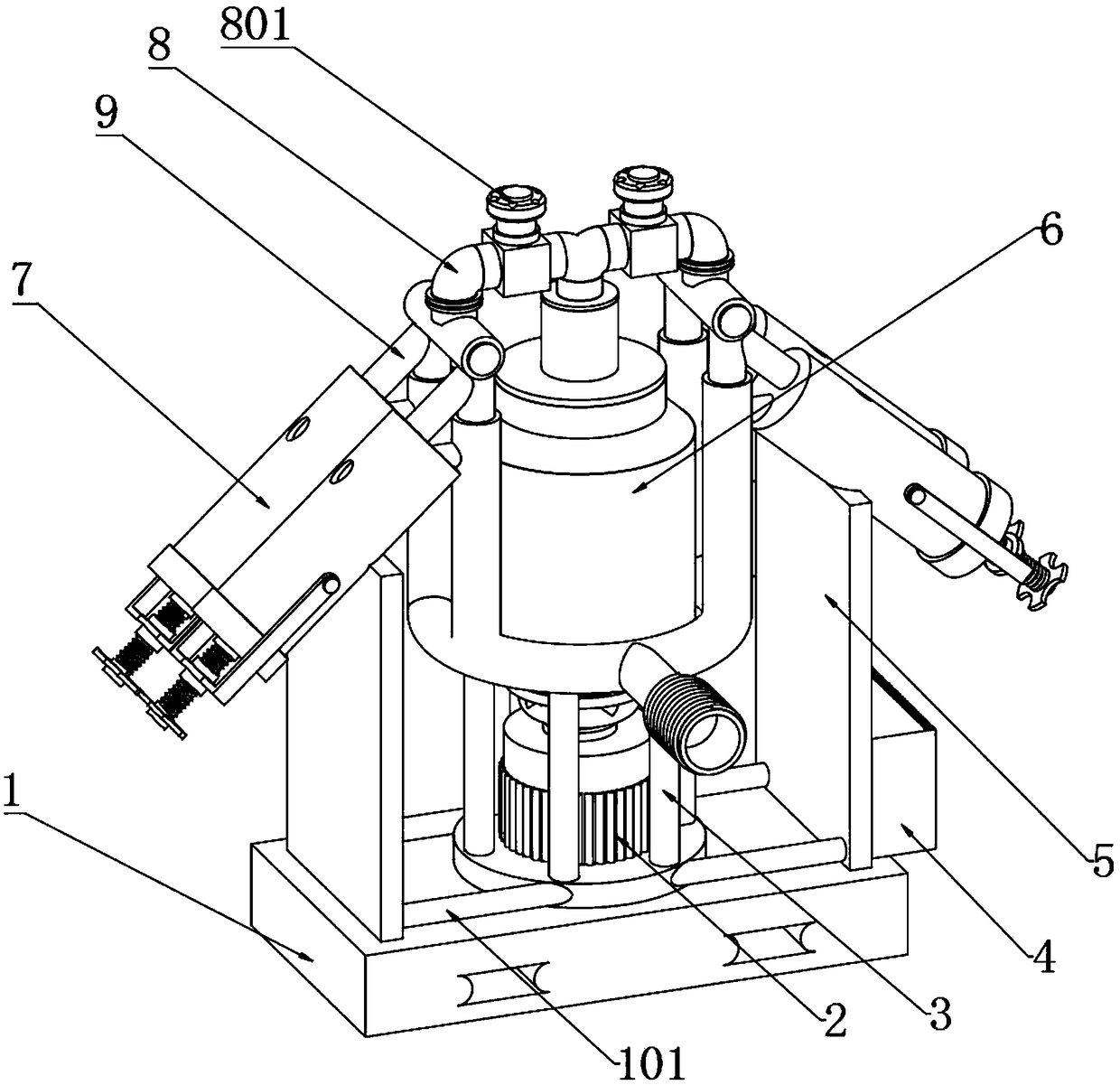

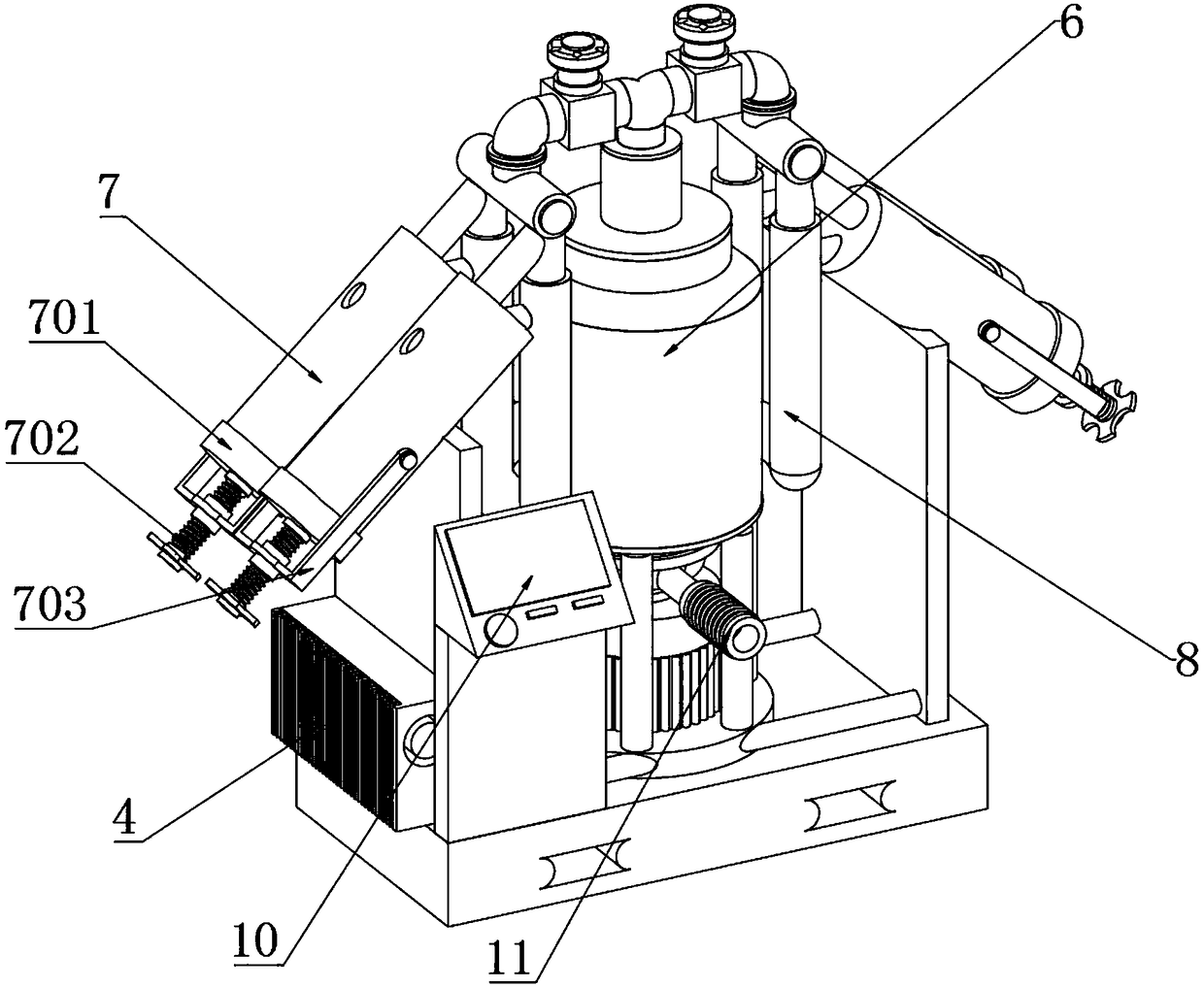

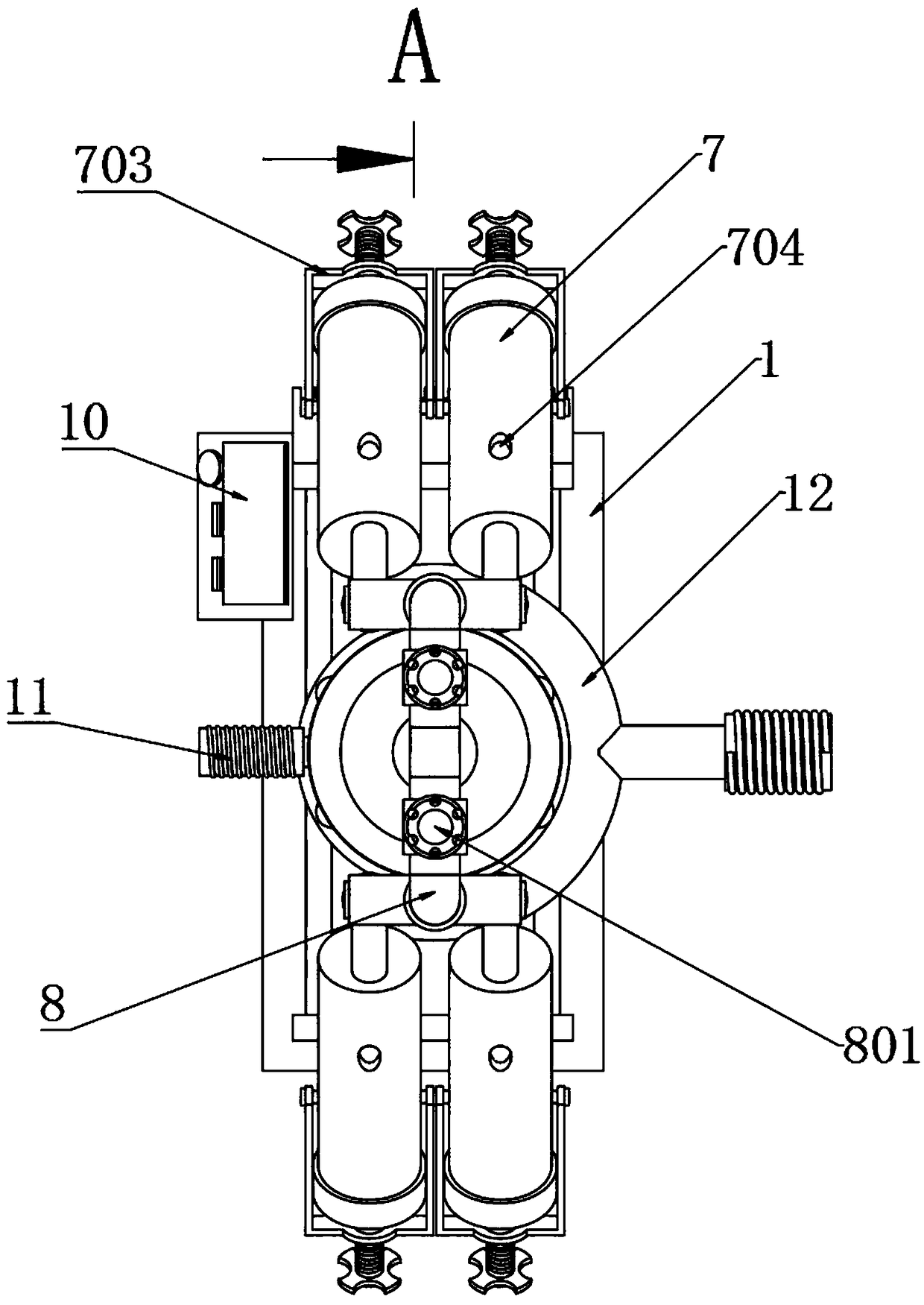

[0039] as attached figure 1 to attach Figure 10 Shown:

[0040] The present invention provides a mineral impurity sedimentation machine, including a support base plate 1, a servo motor 2, a support column 3, a controller 4, a support plate 5, a mixing homogenizer 6, a settler 7, a T-shaped pipe 8, a bifurcated pipe 9, Control panel 10, feed pipe 11, discharge pipe 12, feed deflector 13, I-shaped fixed frame body 101, rotating shaft 601, homogeneous paddle 602, push block 603, push paddle 604, sedimentation cylinder 701, Tightening column 702, fixed frame 703, observation hole 704, electromagnetic control valve 801, material distribution pipe 1101, chemical precipitation purification inner cylinder 70101, return plate 70102 and positioning groove 70201, and the center of the bottom of the support base 1 is fixed with a servo motor 2, and the periphery of the bottom of the servo motor 2 is fixed to the inner bottom end of the vertical rectangular support plate 5 provided at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com