Multi-chamber reciprocation type ocean micro plastic synchronous collection and separation device with sand-removing screw rod

A separation device and synchronous collection technology, which is applied in the direction of sampling device, filtration separation, measurement device, etc., can solve the problems of low separation efficiency and sand particles mixed in microplastics, and achieve the effect of improving collection and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

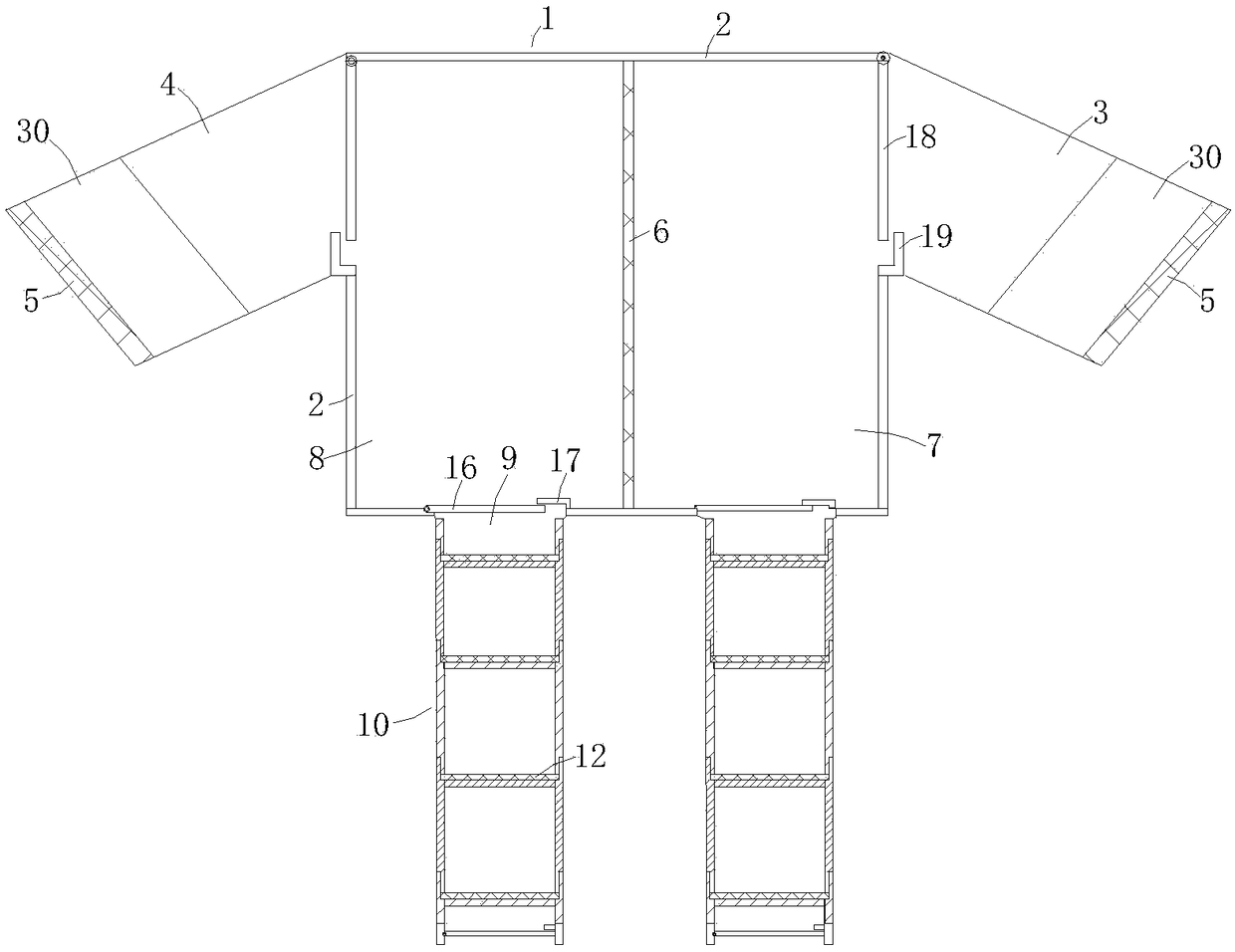

[0035] Such as figure 1 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9As shown, the multi-chamber reciprocating marine microplastic synchronous collection and separation device with sand removal screw includes a microplastic collection box 1, which is surrounded by a plurality of guard plates 2, and the microplastic collection box 1 There are two microplastic one-way inlets facing each other on both sides, the two microplastic one-way inlets are respectively the first microplastic one-way inlet 3 and the second microplastic one-way inlet 4, the first microplastic one-way inlet The plastic one-way inlet 3 and the second microplastic one-way inlet 4 are provided with a filter mechanism, wherein the filter mechanism is a microplastic filter 5, and the microplastic filter 5 is arranged obliquely, and the microplastic filter 5 is mainly used for filtering Large pieces of plastic in seawater prevent large pieces of plastic from entering the microplastic collection b...

Embodiment 2

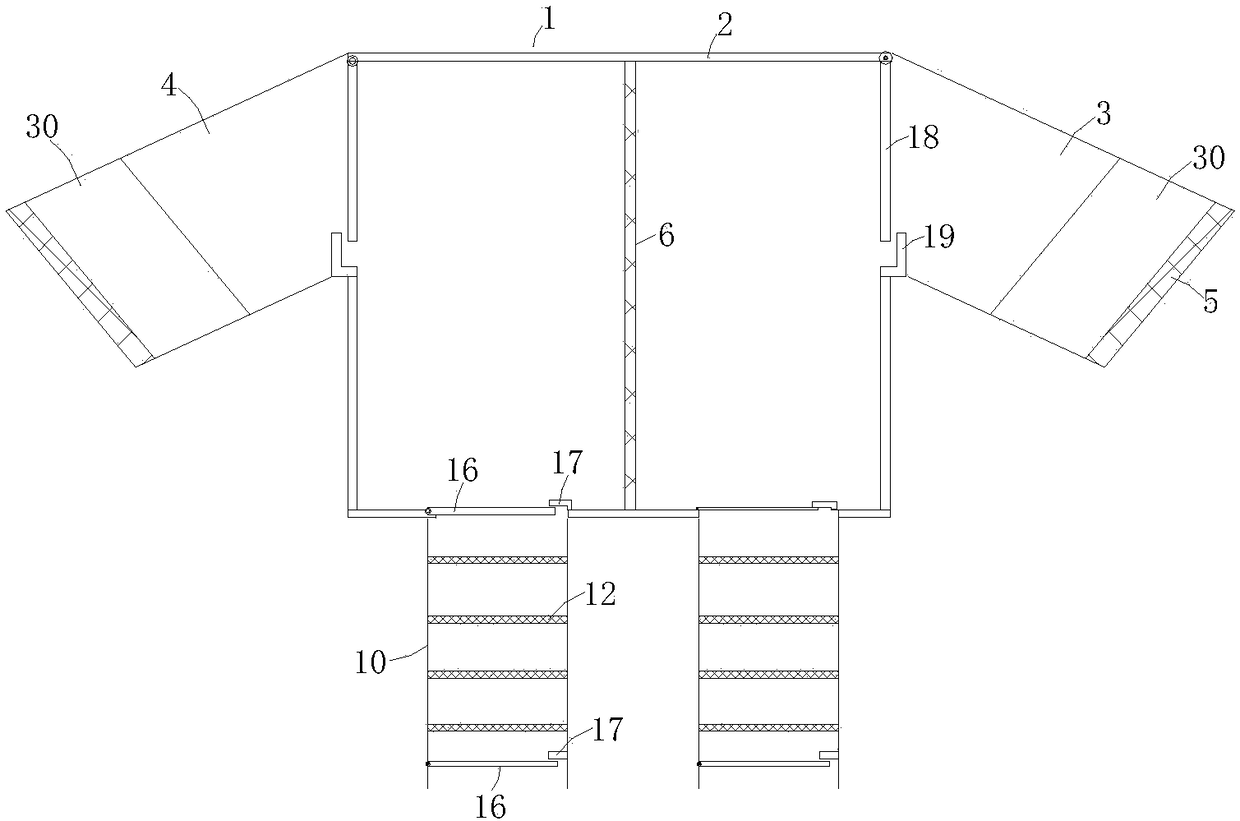

[0048] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the microplastic separation device is different from that of Embodiment 1. The microplastic separation device includes a frame 10 connected to the microplastic collection port 9, and multiple etc. are fixedly installed in the frame 10. The filter membranes 12 arranged at intervals, the apertures of the filter membranes 12 gradually become smaller from near the microplastic collection port 9 to away from the microplastic collection port 9 . In this embodiment, the filter membranes 12 are directly fixed in the frame 10 at equal intervals. Of course, the structure of the microplastic separation device in Example 1 is a preferred solution.

Embodiment 3

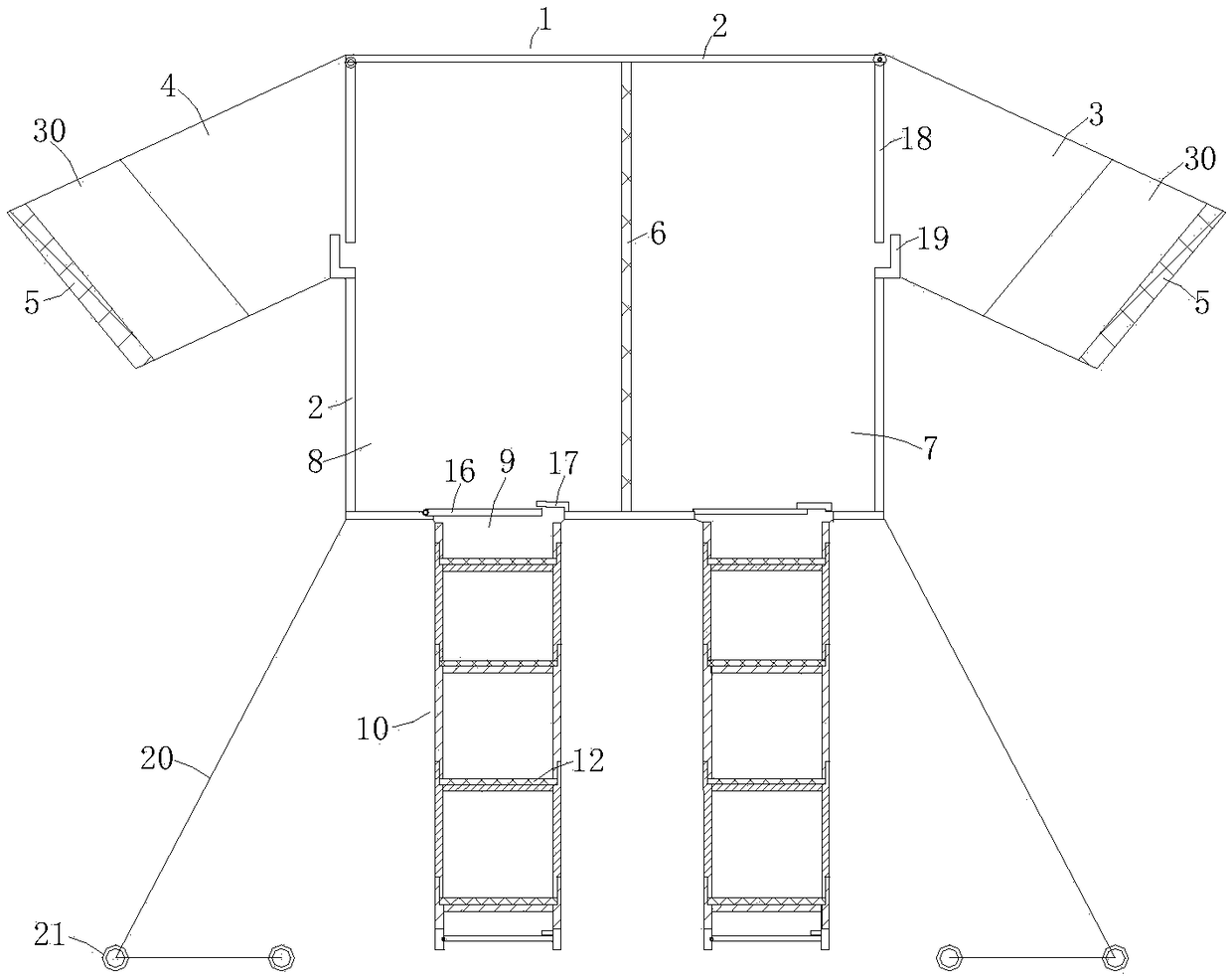

[0050] Such as image 3 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference from Embodiment 1 is that the end of the guard plate 2 is connected to the protective cover 20, and the protective cover 20 is located on the outside of the microplastic separation device. The protective cover 20 is fixed on the coast by the anchor rod 21. In order to facilitate the passage of seawater, the protective cover 20 is woven into a mesh by steel bars. The protective cover 20 mainly plays the role of protecting the microplastic separation device, and can fix the microplastic collection box 1 in addition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com