Full-automatic adhesive pouring machine with double vacuum tanks

A technology of vacuum box and glue filling machine, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of affecting product quality, large energy consumption of equipment, long time for vacuuming and pressurization, etc., to shorten the time. The effect of pressure processing time, stable and reliable transmission, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

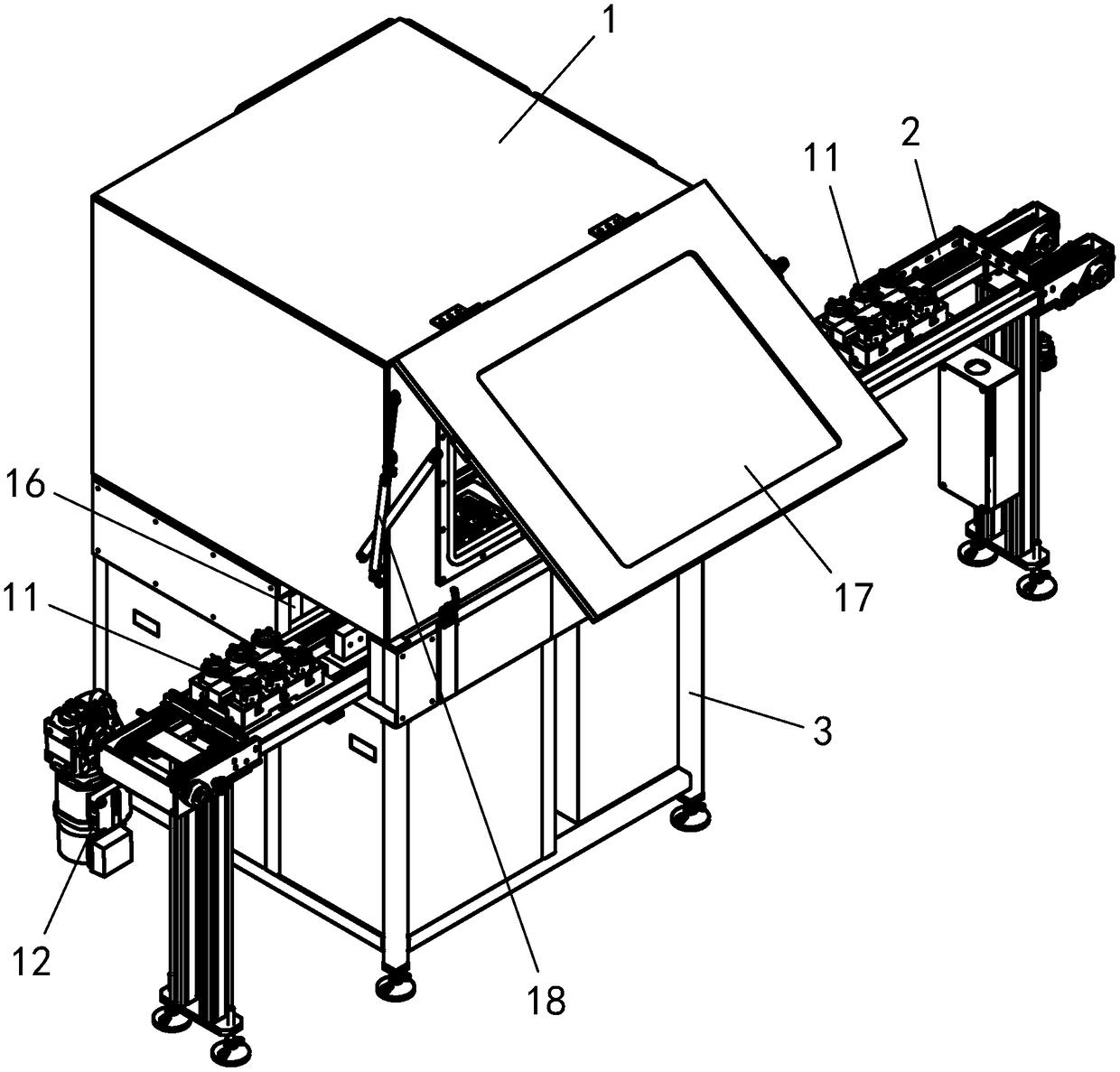

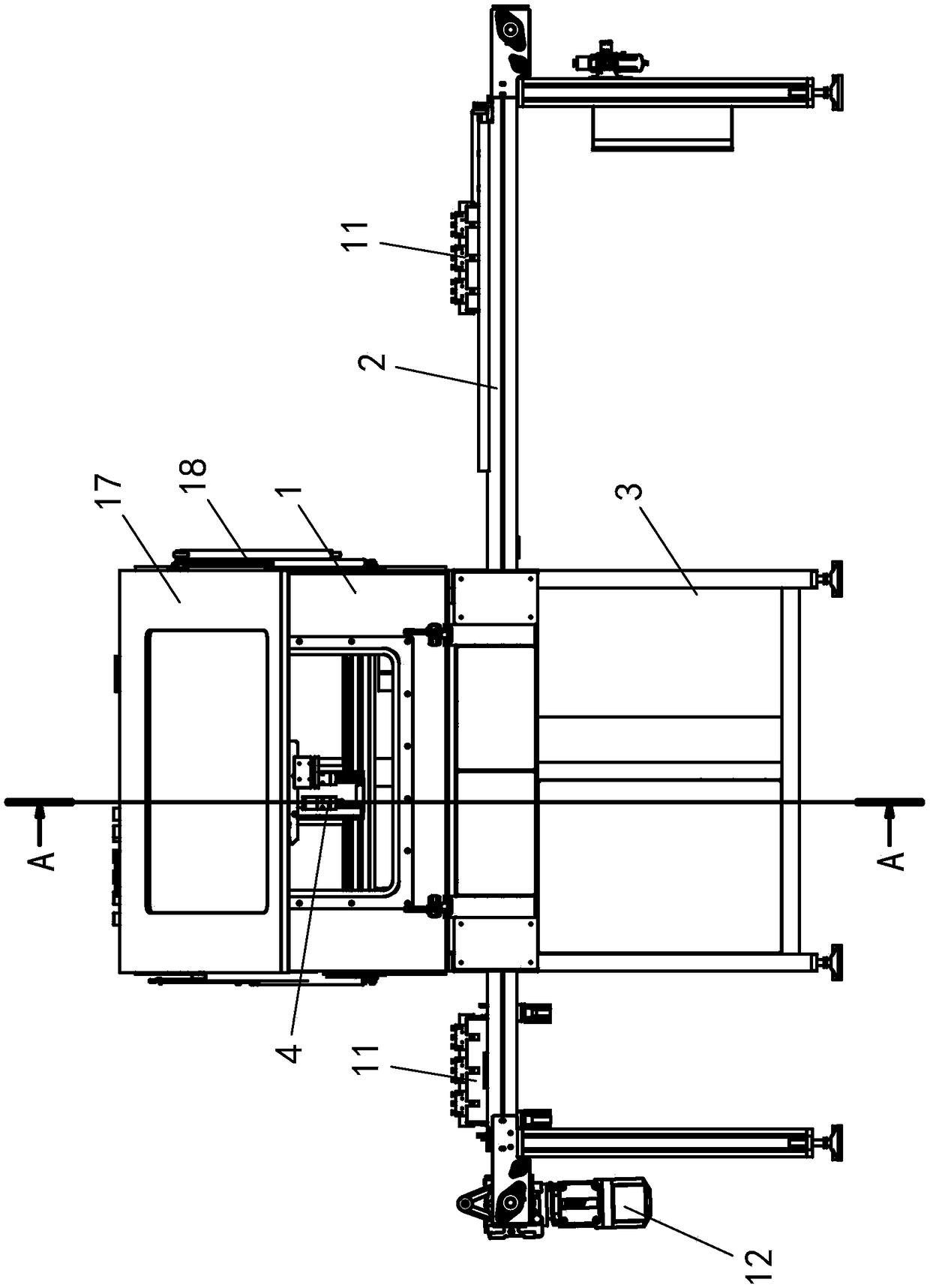

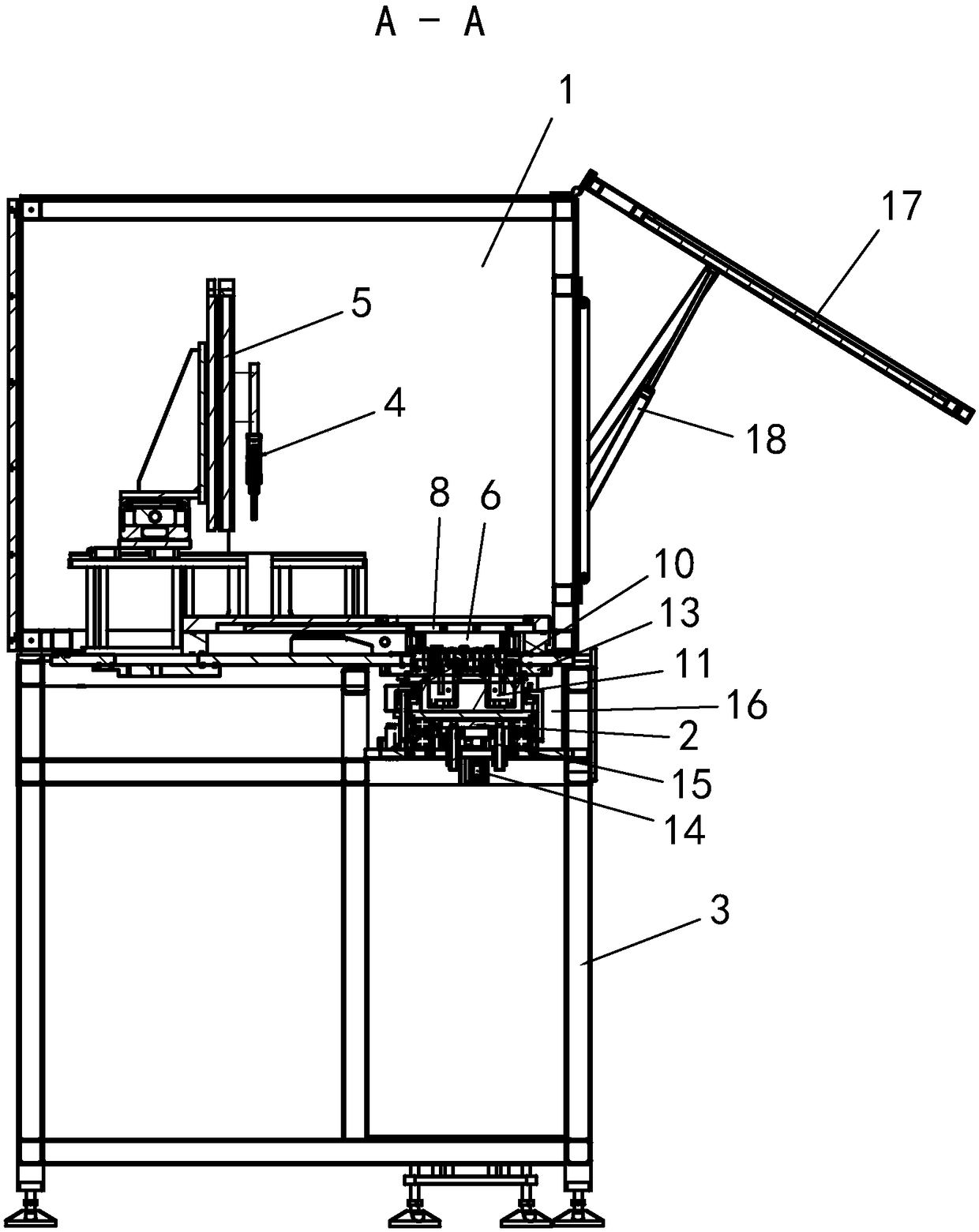

[0039] Example: see attached Figure 1~11 As shown, a fully automatic double vacuum box glue filling machine includes a vacuum glue filling box 1 and a product conveying line 2; the vacuum glue filling box 1 is fixed on the equipment rack 3, and the inside of the vacuum glue filling box 1 There is a glue valve 4, which is controlled by a three-axis manipulator 5 and is used to fill the product with glue.

[0040] It also includes a small vacuum box 6, which is connected to the vacuum glue box 1 and communicates with the inner cavity of the vacuum glue box 1 through a first opening 7; the first opening 7 passes through A plate body 8 is sealed or opened. The plate body 8 is driven by a first cylinder 9 to move in translation, and the first opening 7 corresponds to the dispensing valve 4; the inner cavity of the small vacuum box 6 is used for The volume of the product containing the product is larger than the volume of the product but smaller than the volume of the inner cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com