A kind of borosilicate glass, anti-halation input window glass and preparation method thereof

A borosilicate glass and window glass technology, applied in the field of optical materials, can solve the problems of high color center or reducible ion concentration, low cathode sensitivity of anti-halation input window, etc. Sensitivity requirements, good stray light elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

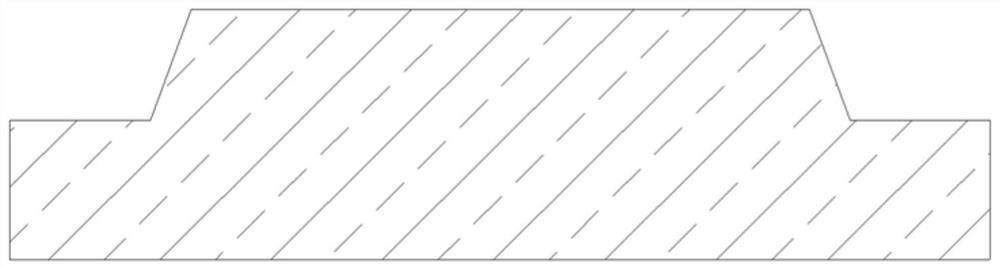

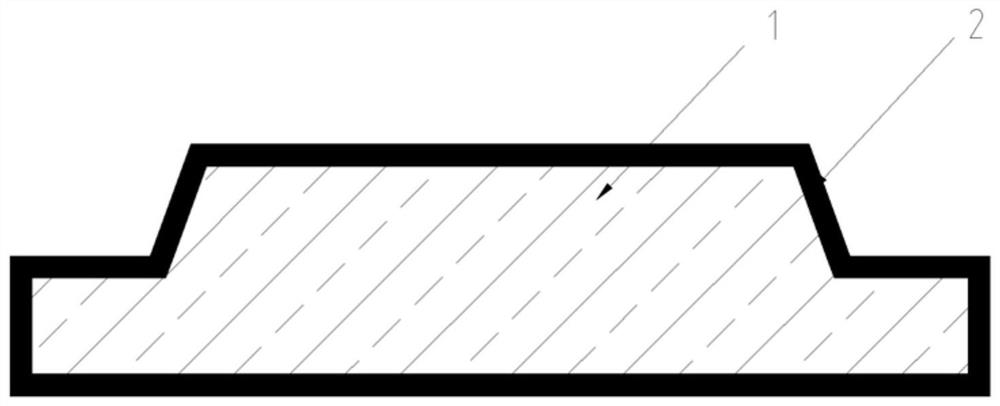

[0055] Weigh the corresponding oxides or compounds according to the glass components in Table 1, put them into a mortar, grind them and mix them evenly, then add them to a platinum crucible, and melt them at 1520°C for 10 hours. Pour the molten glass into a mold to form it, then put it in a Maofu furnace at 520°C for 2 hours, then turn off the power to cool down. The glass cooled to room temperature is taken out to make stepped glass (such as figure 1 shown); then put the stepped glass into a closed container and heat it to 595°C, fill it with hydrogen, the hydrogen pressure is 0.17MPa, keep the pressure for 200 hours, and change the hydrogen every 12 hours. Get as figure 2Anti-halation input glazing shown, where 1 is the clear glass portion and 2 is the black glass layer.

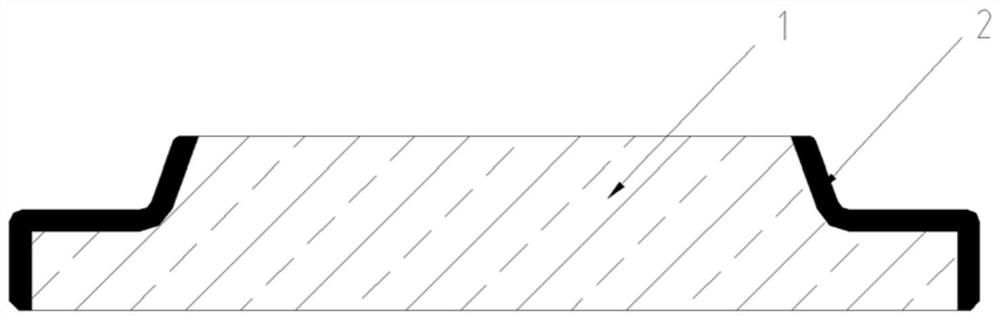

[0056] Grind and remove the black glass layers on the upper and lower sides of the above-mentioned anti-halation input window glass, leak the transparent glass inside, and keep the black glass layer on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com