Installation system shared by ceramic plates and ceramic sheets

A ceramic thin plate and ceramic plate technology, applied in covering/lining, building, building structure, etc., can solve the problem of high installation cost, and achieve the effect of reducing the difficulty of processing and installation, good fixing effect and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

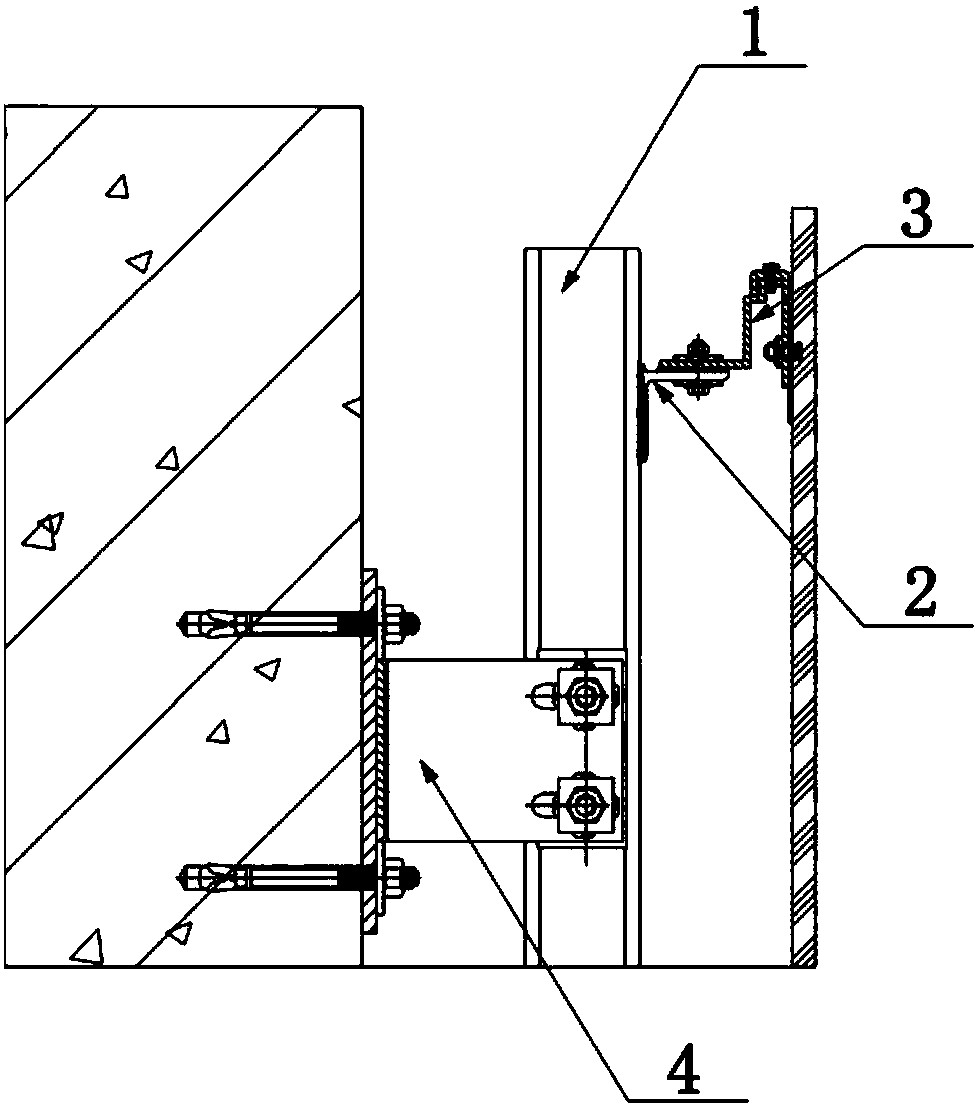

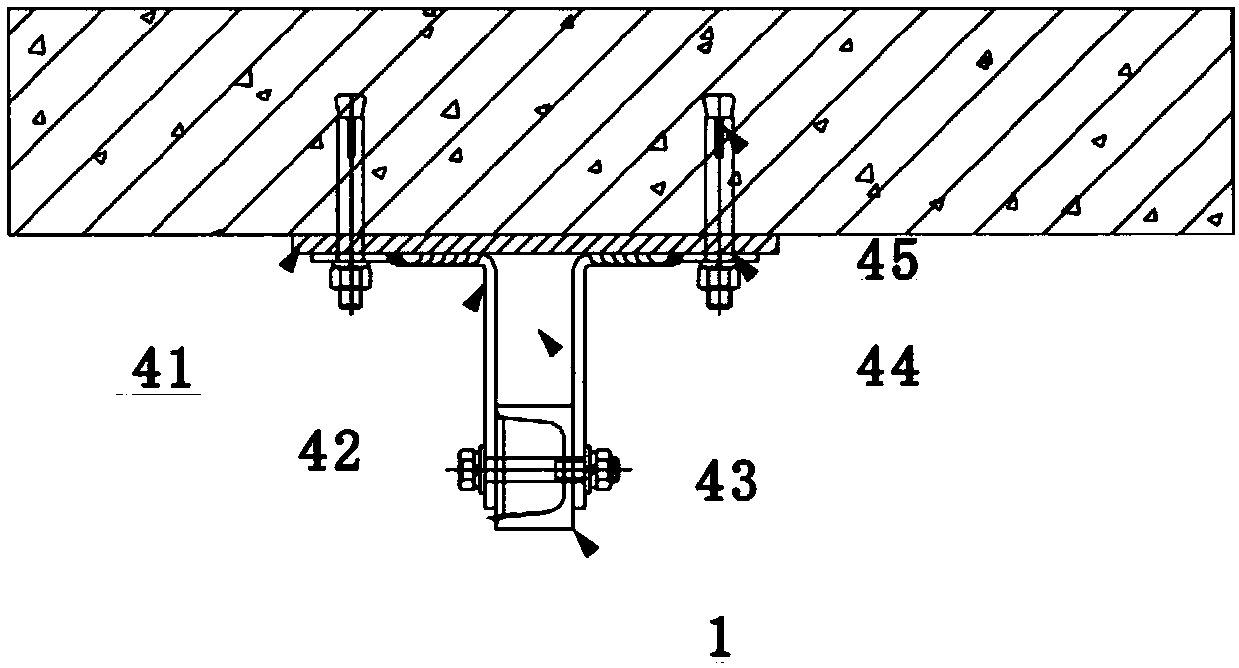

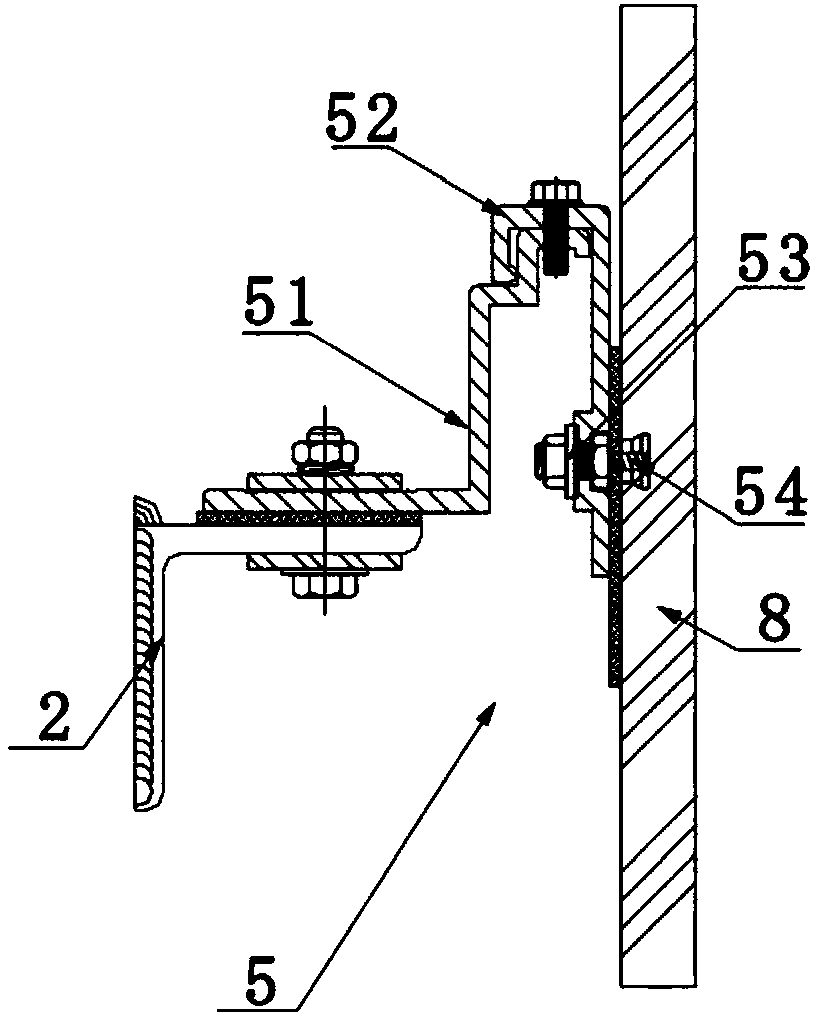

[0032] In the embodiment of the present invention, such as Figure 1-7 As shown, an installation system shared by ceramic plates and thin ceramic plates is provided, and the installation system includes fixing components, ceramic plates 8 and ceramic thin plates 9 . Wherein, the fixing assembly includes a horizontal keel 2 , a vertical keel 1 and a plate fixing part 3 . Vertical keel 1 is preferably channel steel, and preferably galvanized channel steel, such as 6.3# galvanized channel steel, to prevent vertical keel 1 from corrosion. The vertical keel 1 is vertically fixed on the wall through the connecting piece 4. The connecting piece 4 includes an iron plate 41 and two angle steel adapters 42. The angle steel adapter 42 is welded on the iron plate 41, and the two angle steel adapters are connected The parts 42 are relatively arranged...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap