Automatic drill pipe mounting and dismantling device and engineering drilling machine

A technology for loading and unloading devices and drill pipes, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of complex structure, low time-consuming efficiency, limited thrust and stroke length, etc., and achieve the effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

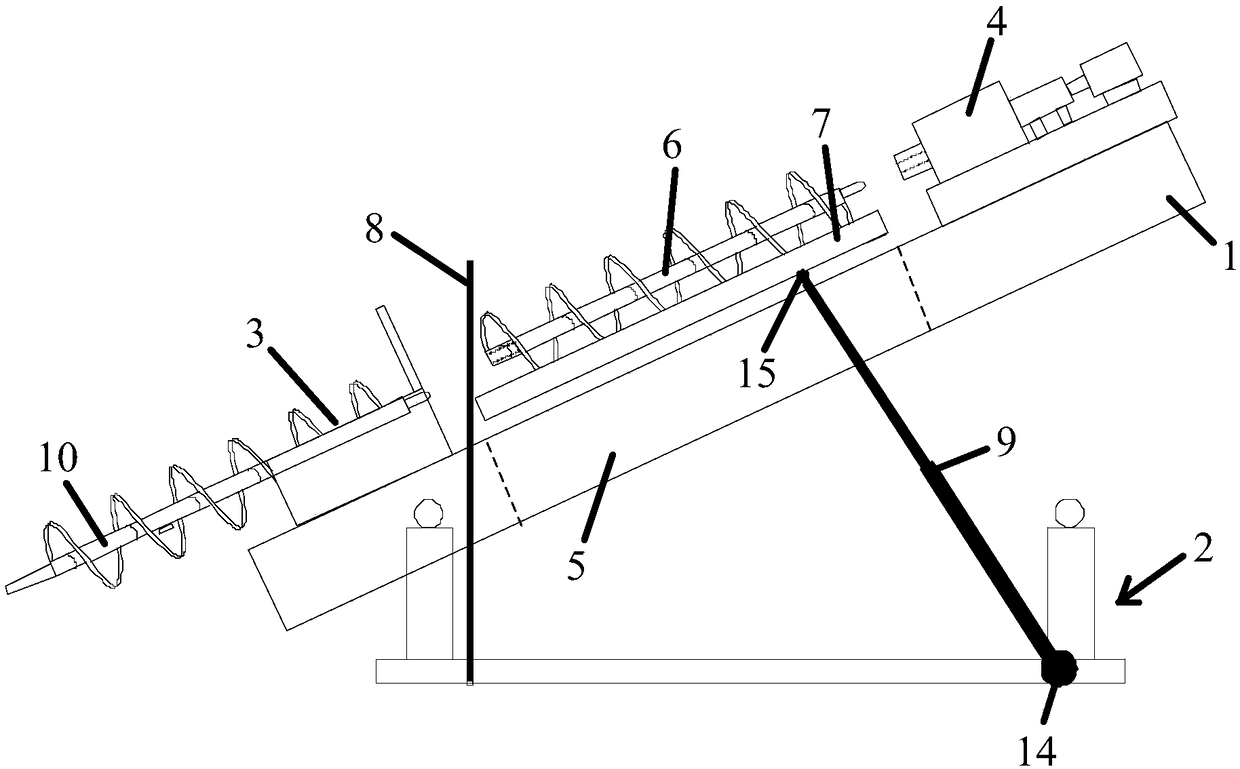

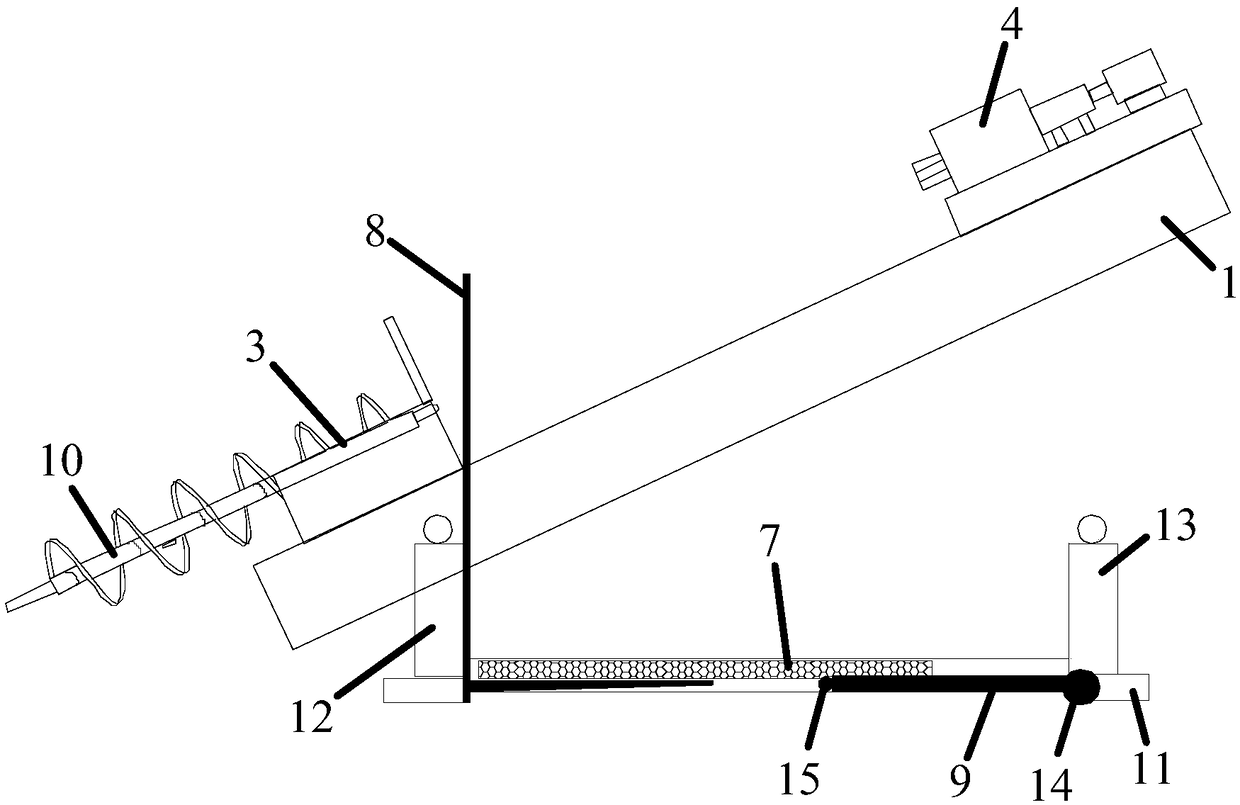

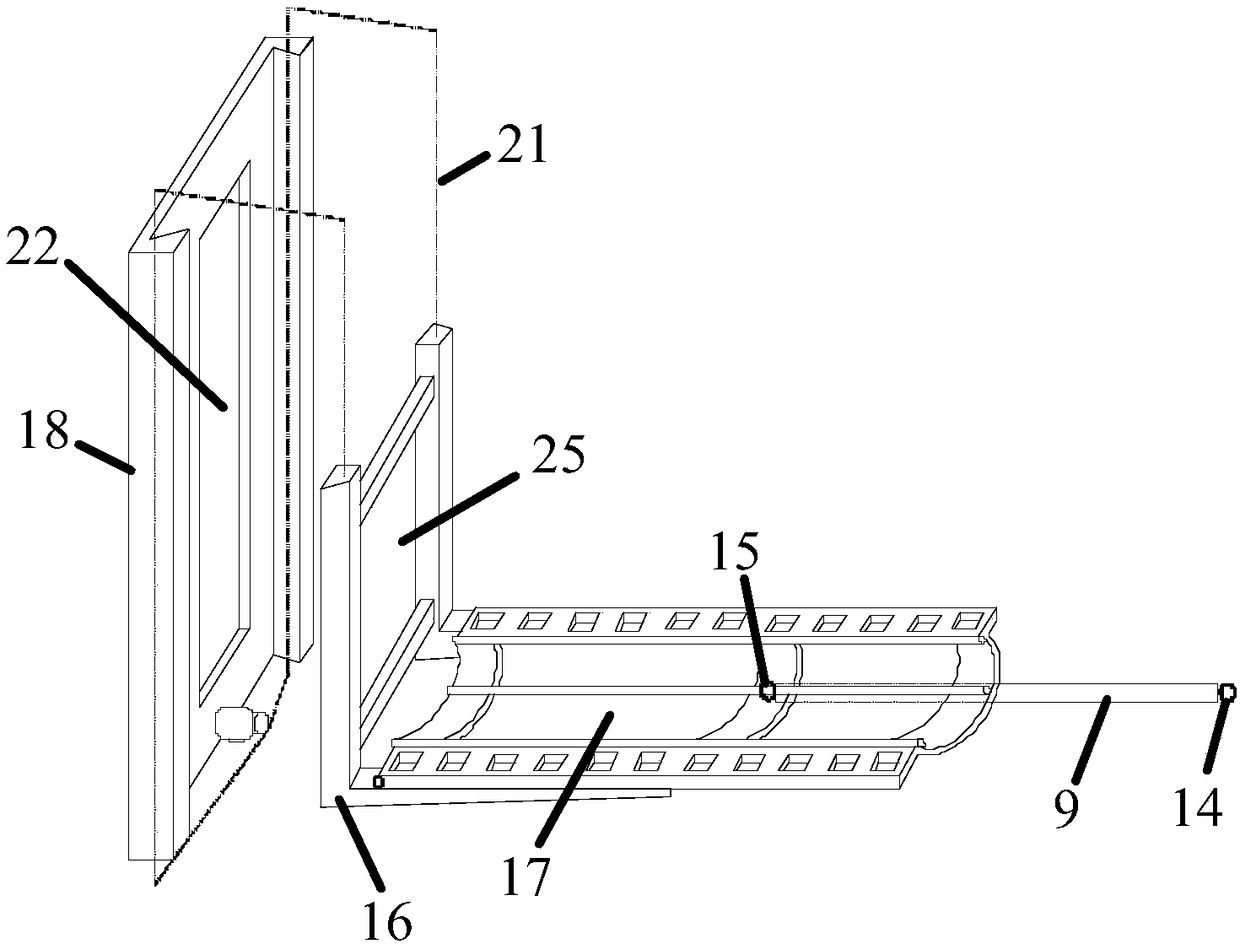

[0049] A kind of open-pit mine end side mining auger drilling machine of this embodiment, such as figure 1 and figure 2 shown, including:

[0050] Drilling rig platform 1, said drilling rig platform 1 is provided with working drill pipe 3, propulsion machine 4 and the loading and unloading drill pipe transfer for transferring or removing loading and unloading drill pipe 6 between said working drill pipe 3 and said propulsion machine 4 channel 5;

[0051] The drilling rig foundation 2 includes a support base plate 11, a first support platform 12 arranged on the support base plate 11 and connected to the front of the drilling rig platform 1 in rotation, and a first support platform 12 that is detachably connected to the rear of the drilling rig platform 1 The second support platform 13, the drilling rig platform 1 is hinged on the first support platform 12, and is driven to carry the working drill rod 3 connected with the drill bit 10 to rotate counterclockwise and tilt down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com