Double check valve integrated device applicable to automobile fuel vaporization system

A technology of fuel evaporation system and double check valve, which is applied in the direction of charging system, engine components, machine/engine, etc., can solve the problems of large number of parts, large space occupation, large intake air volume, etc., and achieve the goal of reducing space Occupancy, the overall component structure is small, and the effect of reducing the number of press-fitting steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

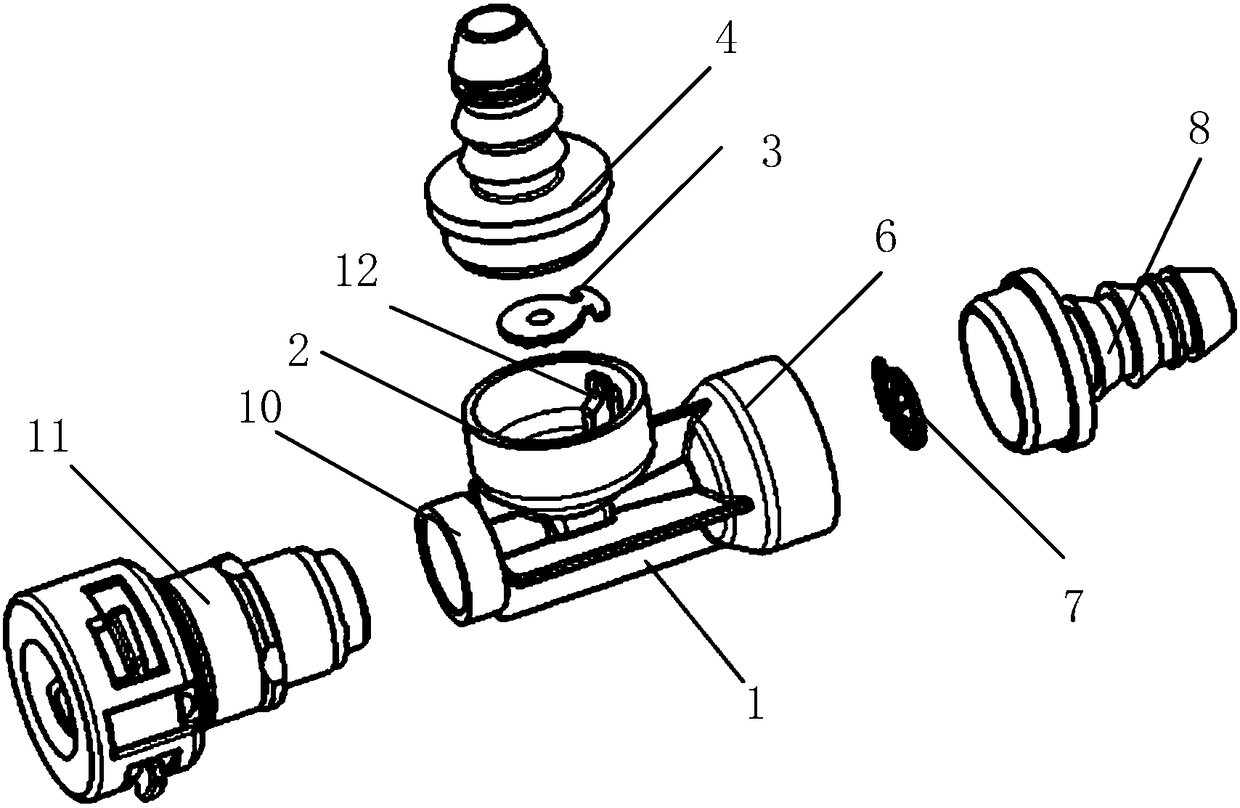

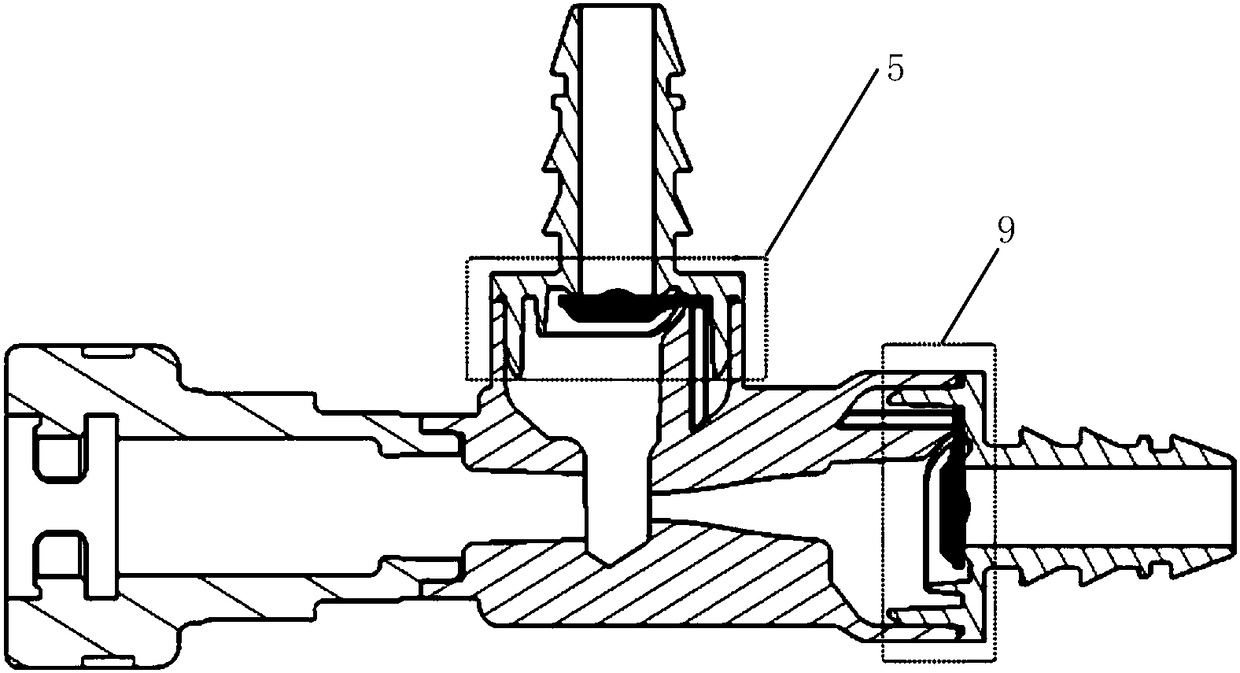

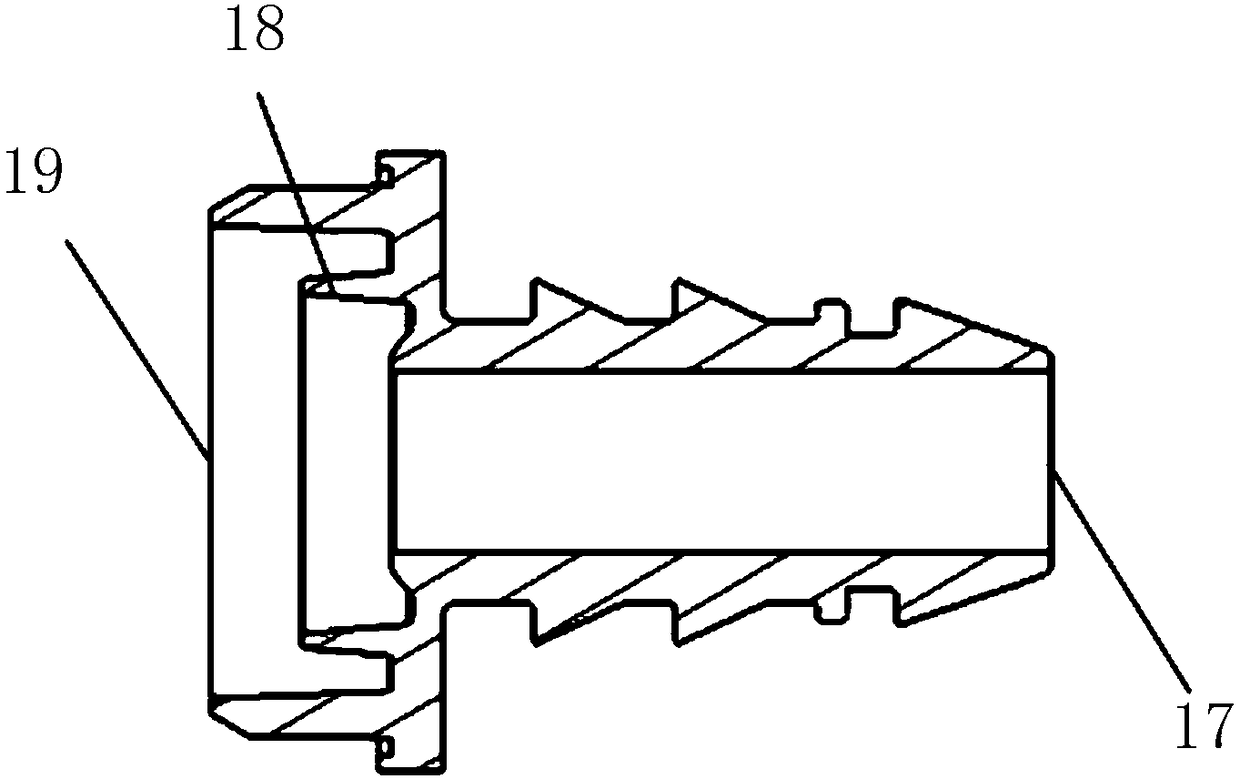

[0042] Such as Figures 1 to 6 An integrated double check valve device suitable for automotive fuel evaporation systems, including a venturi body 1, a Venturi structure is arranged in the venturi body 1, and its difference lies in: in order to realize the one-way The main connecting end 2 located on the top of the Venturi tube body 1 is provided with a main valve plate 3, and the main connecting end 2 is connected with a main end cover 4 to form a first check valve structure 5. . Correspondingly, an auxiliary valve plate 7 is disposed in the auxiliary connecting end 6 located on the side of the venturi body 1 , and an auxiliary end cover 8 is connected to the auxiliary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com