Self-guiding gentle wind power generation equipment

A power generation equipment and self-guiding technology, applied in wind power generation, mechanical equipment, and wind turbines consistent with the wind direction, etc., can solve the problems of inability to ensure the air collection port, loss of wind energy, and utilization of wind energy, so as to increase the effect of wind collection, Effect of reducing energy loss and protecting power generation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

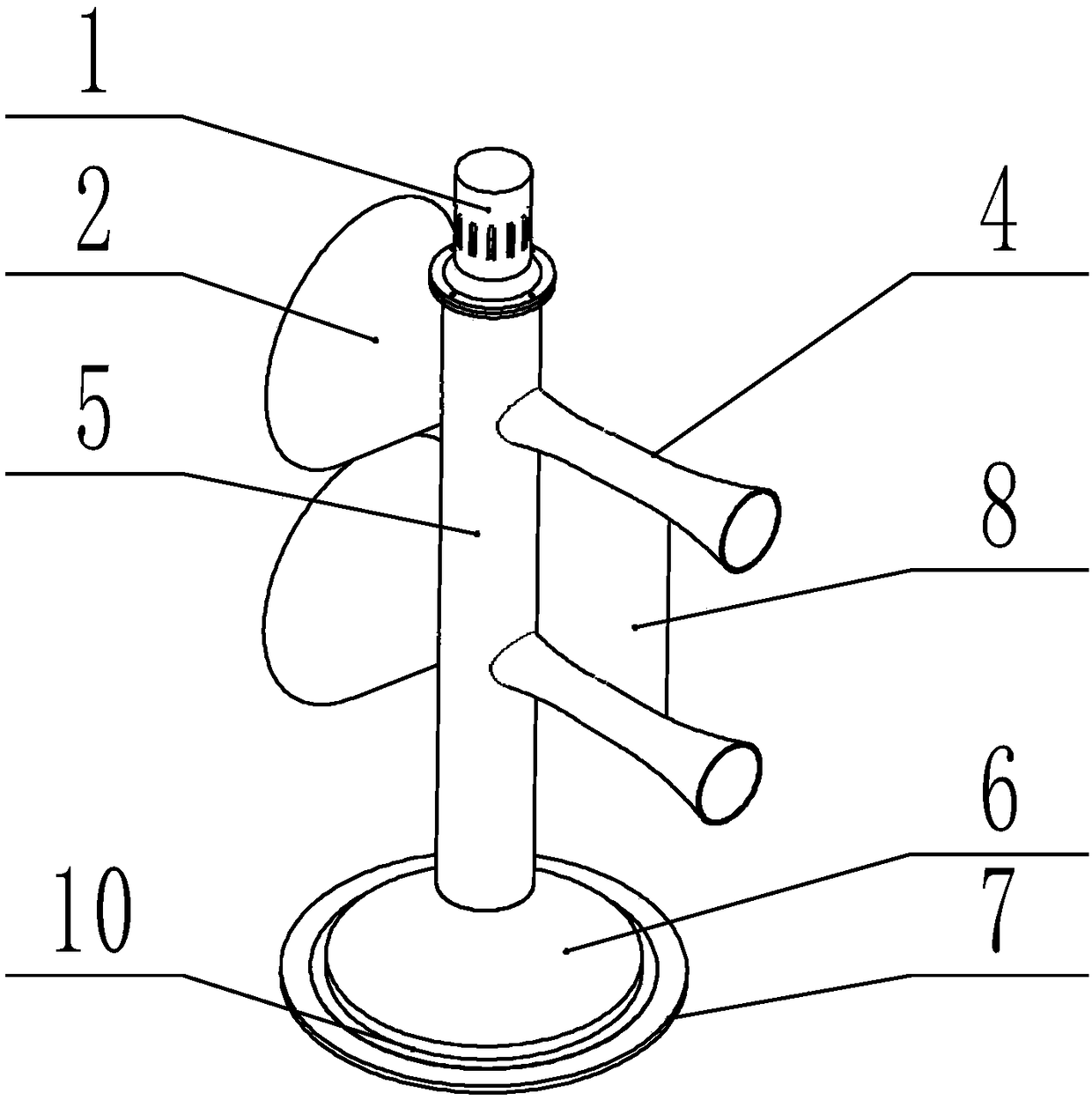

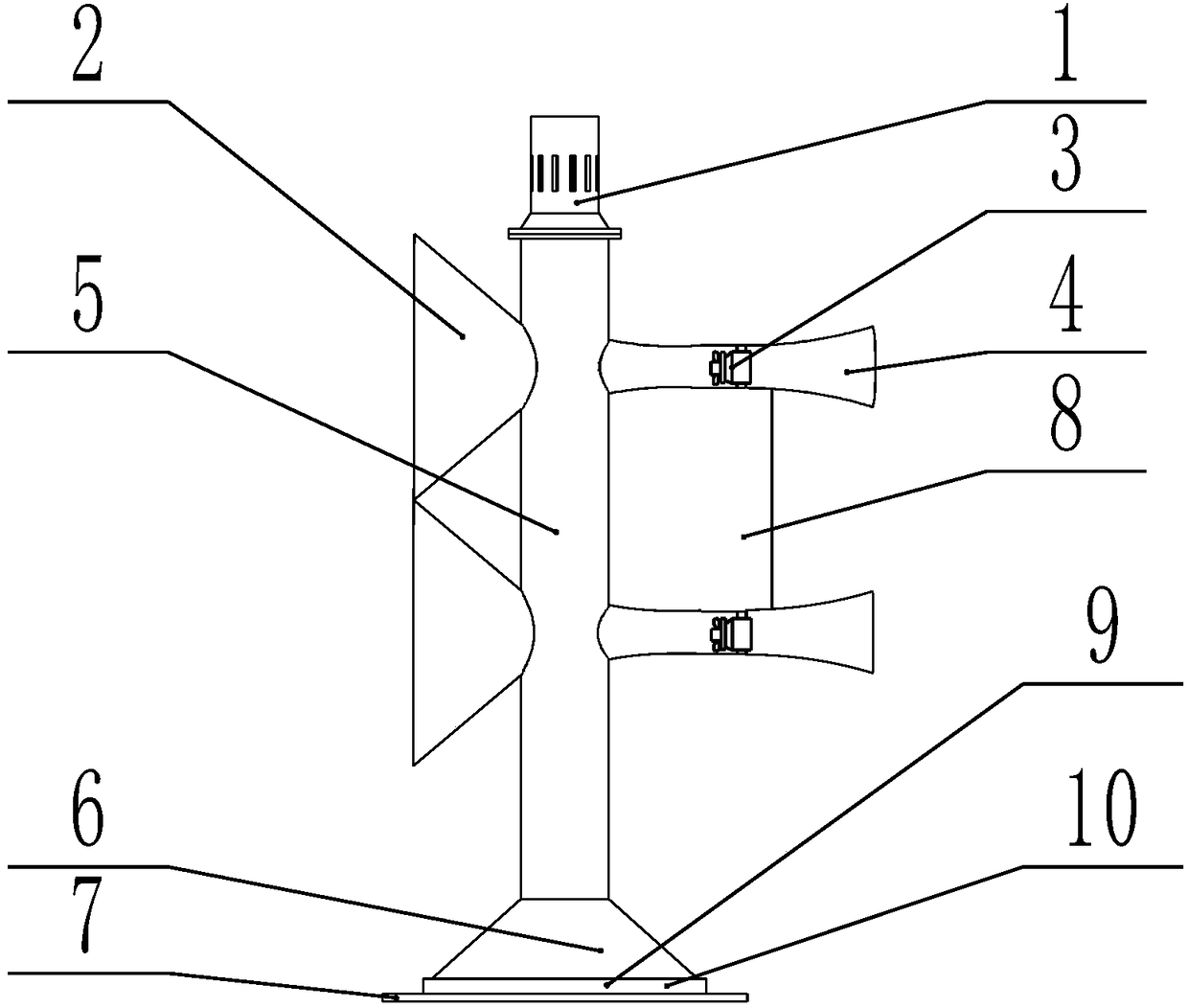

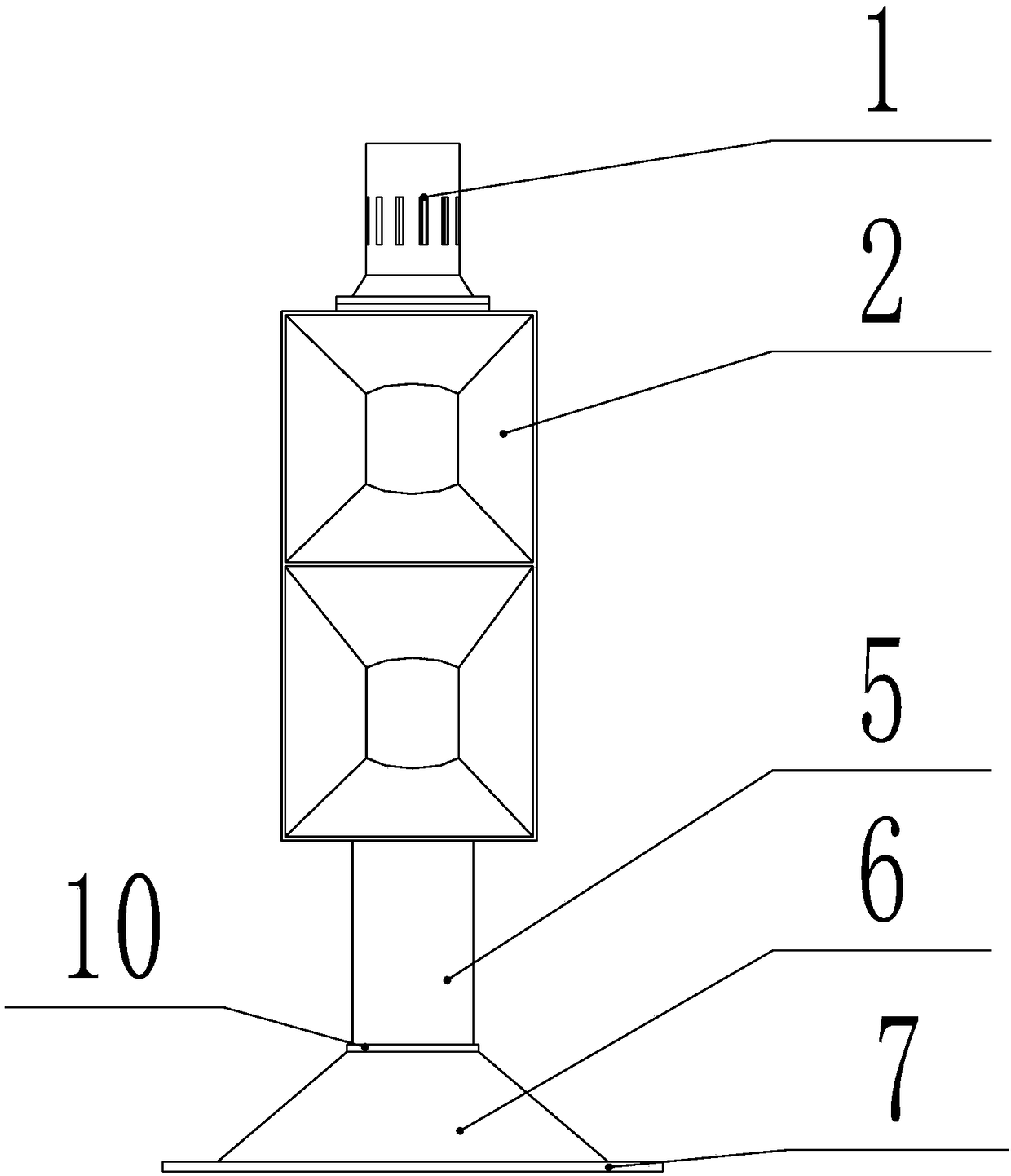

[0021] The invention provides a kind of self-guided breeze power generation equipment (see Figure 1-4 , referred to as equipment), is characterized in that the equipment includes a lightning protection device 1, a horn-shaped wind collector 2, a wind generator 3, an acceleration tube 4, a tubular tower 5, a boss 6, a base 7, a guide plate 8, a ball 9 and a ball plate 10;

[0022] The base 7 is circular and fixed on the ground; the boss 6 is circular and mounted on the base 7 for installing the tubular tower 5; the lower end of the tubular tower 5 is connected with the boss 6, and the tubular tower 5 A lightning protection device 1 with vents is installed on the top, and the lightning protection device 1 plays the role of reducing wind re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com