Scroll compressor

A scroll compressor and scroll groove technology, which is applied in the field of scroll compressors, can solve the problems of leakage at the head of the scroll, inability to form a pressure difference, and reduction in compressor efficiency, so as to achieve reliable adhesion, improved effect, and improved efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

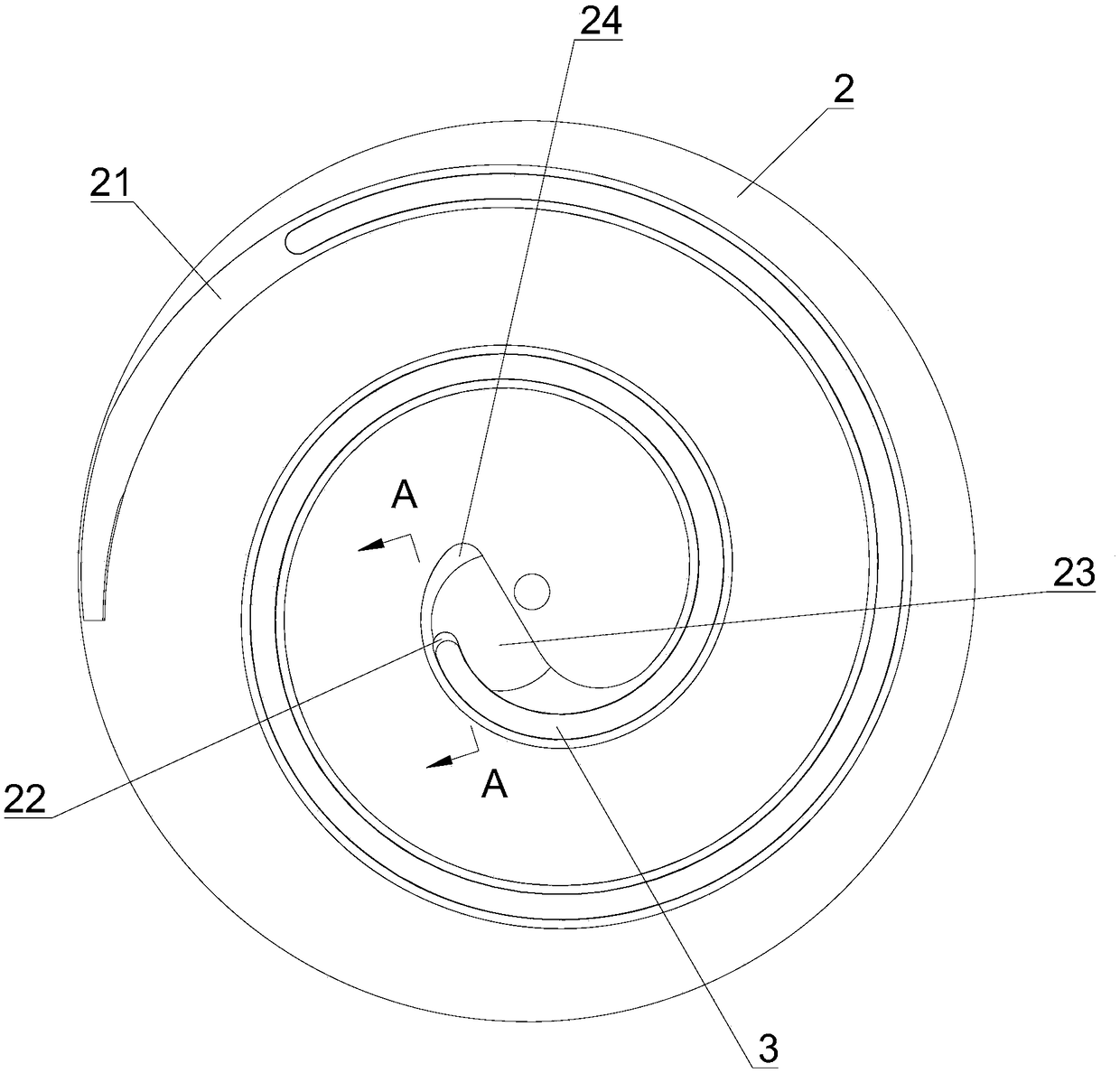

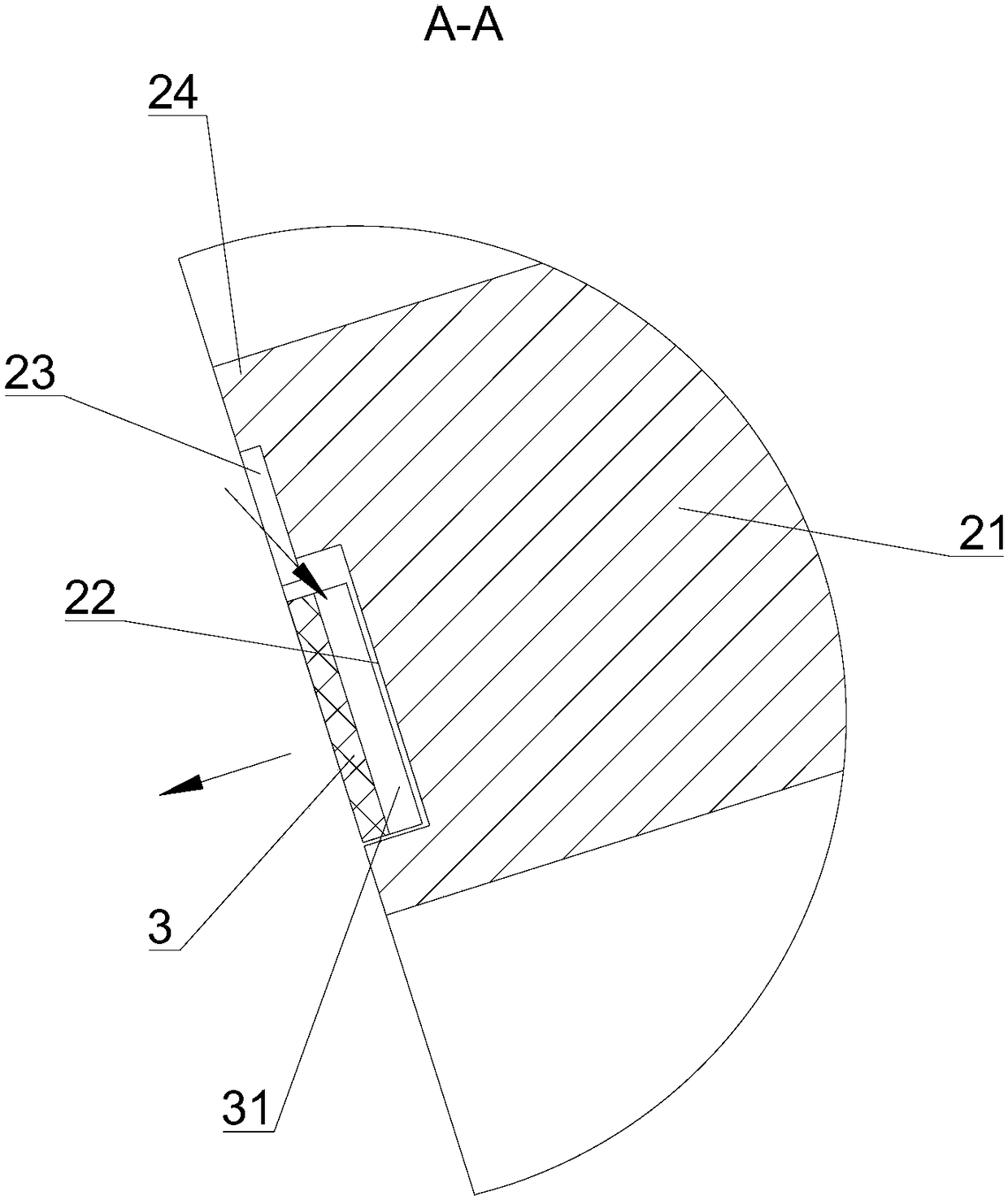

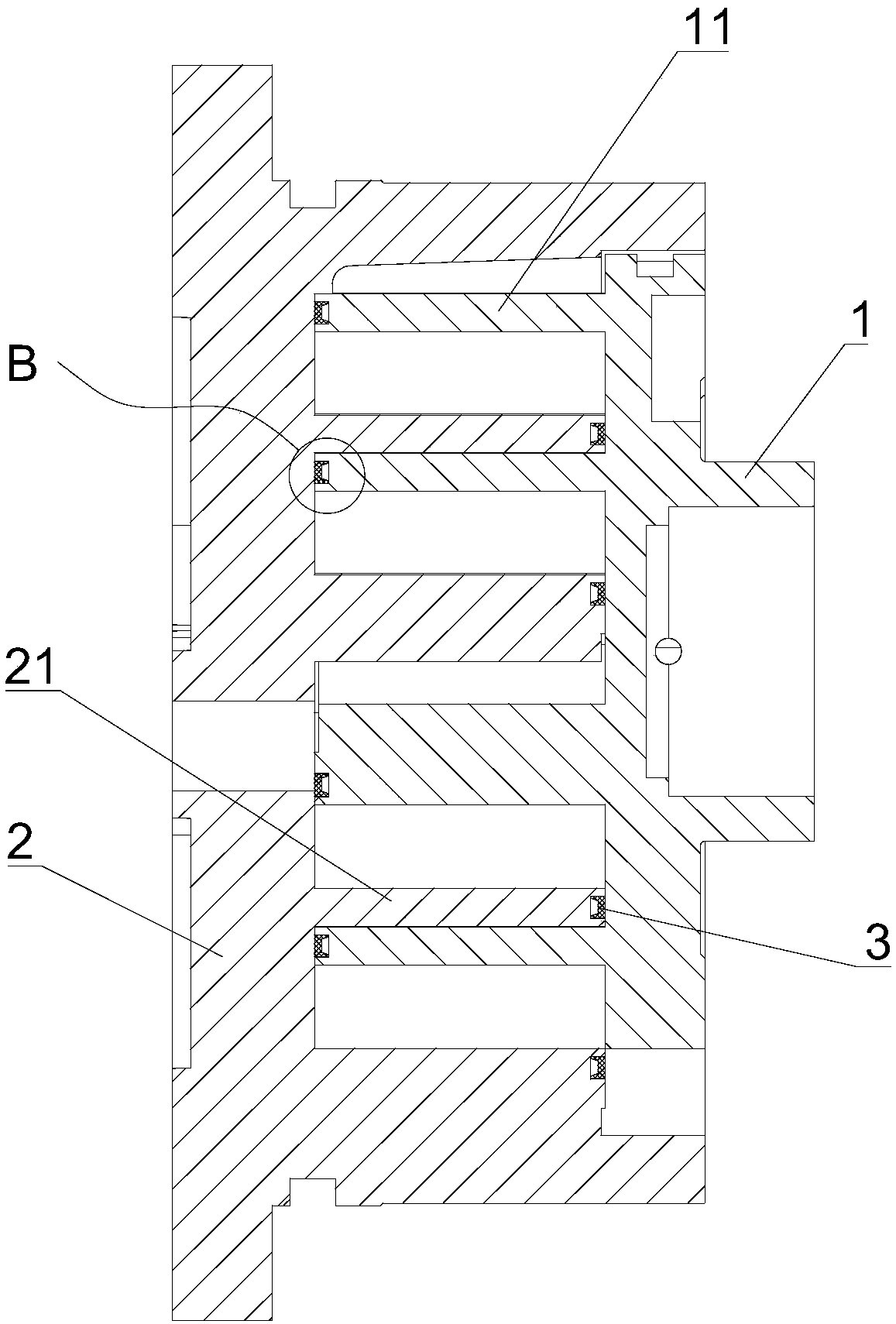

[0031] see Figure 1-5 As shown, the present embodiment provides a scroll compressor. The scroll compressor mainly includes two similar scrolls, which are respectively called the movable scroll 1 and the fixed scroll 2, and the movable scroll 1 and the fixed scroll The spiral coil parameters of the scroll disk 2 are the same, and the phase angle difference is 180°. After the two are assembled together, several pairs of closed crescent-shaped volume cavities can be formed, that is, the compression cavity, and the cavity near the central exhaust hole is the highest. The central high-pressure chamber of pressure is called the first compression chamber 4 , and the two crescent-shaped volume chambers adjacent to the periphery of the first compression chamber 4 are the second compression chambers 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com