Ultra-wide-chord trigonometric waveform blade

A trigonometric function and vane technology, which is applied in the field of ultra-wide chord trigonometric function waveform vanes, can solve problems such as efficiency reduction, achieve the effects of increasing single-stage pressure ratio, wide application prospects, and reducing the number of compressor stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

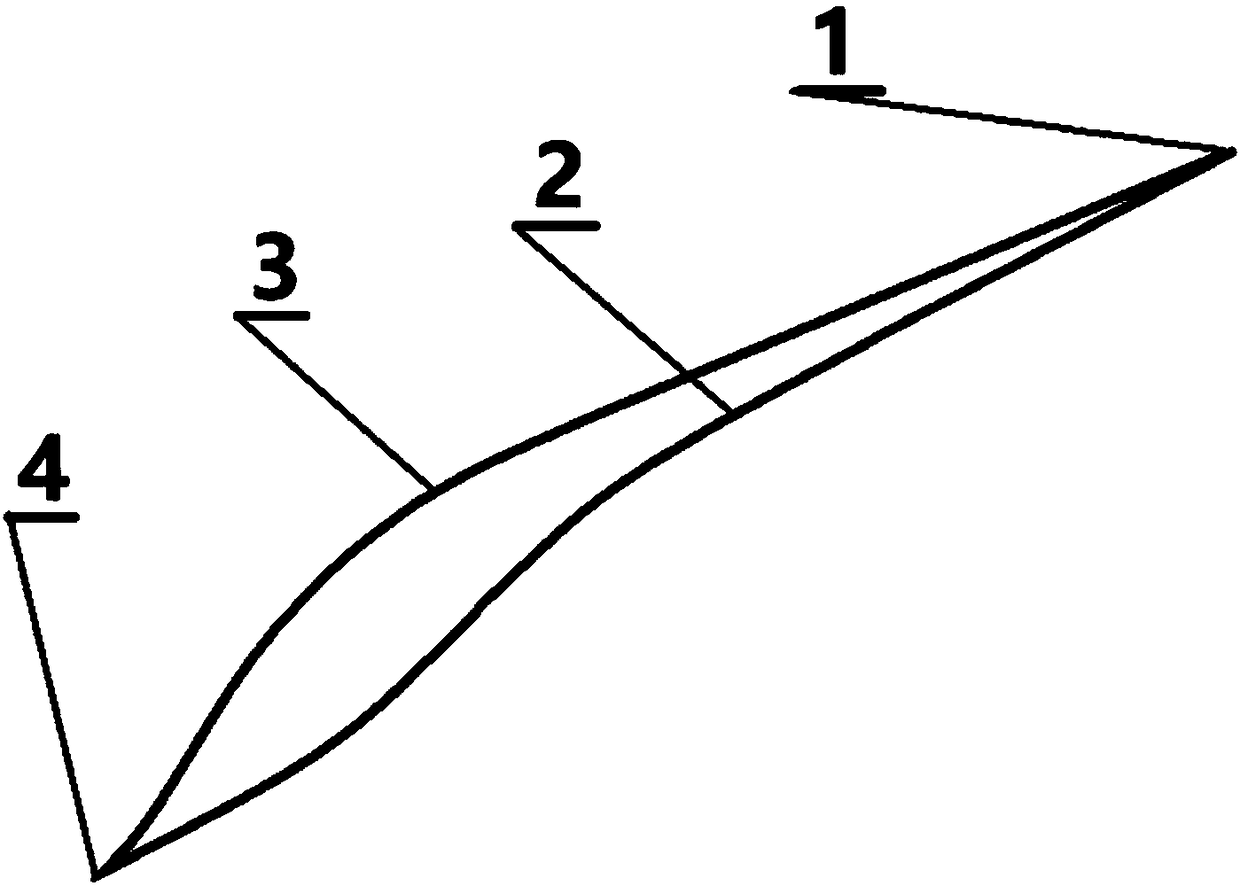

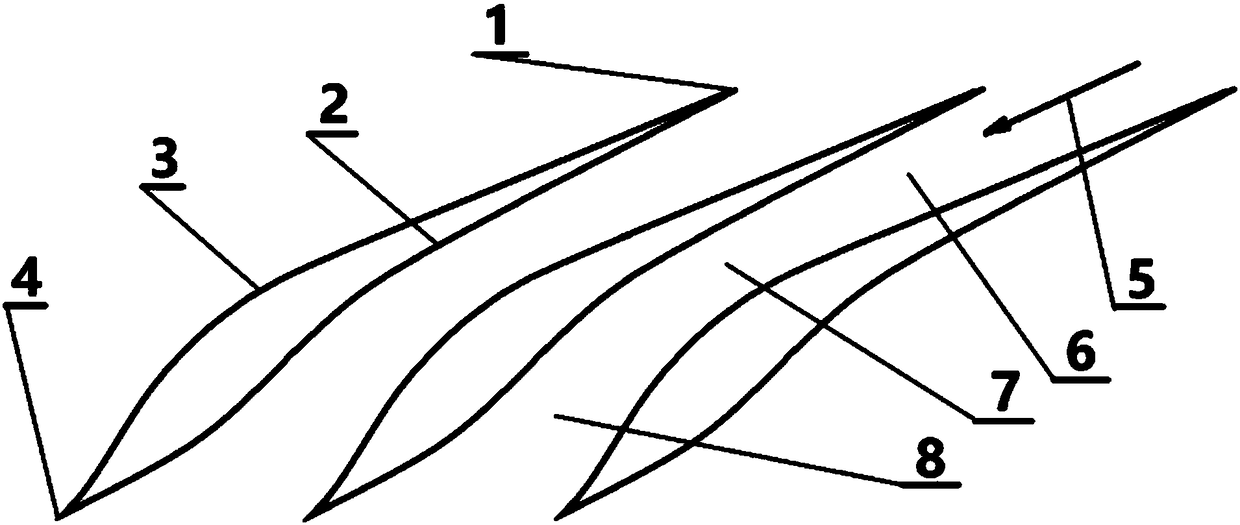

[0028] exist figure 1In the shown structure, a blade profile that can work under the condition of supersonic incoming flow is provided. The profile pressure surface 2 and the profile suction surface 3 are intercepts of two trigonometric function cotangent waveform curves section, the period of the waveform of the airfoil pressure surface 2 is longer than the period of the airfoil suction surface 3 waveform, there is a certain distance between the two cotangent waveforms, both of them are inclined to the right, and the two wave curves intersect on the airfoil The leading edge 1 and the trailing edge 4 of the airfoil; it can be seen from the figure that the retained part of the front part of the pressure surface 2 and the suction surface 3 is longer, and the two form a sharp wedge. This wedge structure can re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap