Welding joint for fixing fire-fighting corrugated pipe

A technology of welding joints and corrugated pipes, which is applied in the direction of pipes/pipe joints/fittings, elbows, siphons, etc., can solve the problems of undurable joints and leakage, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

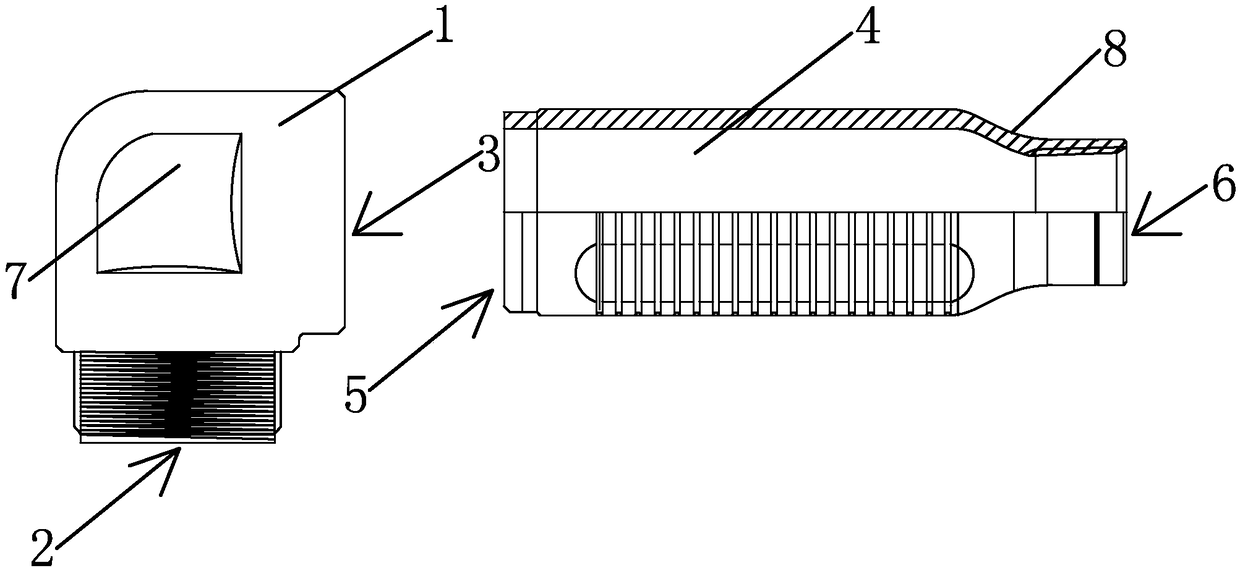

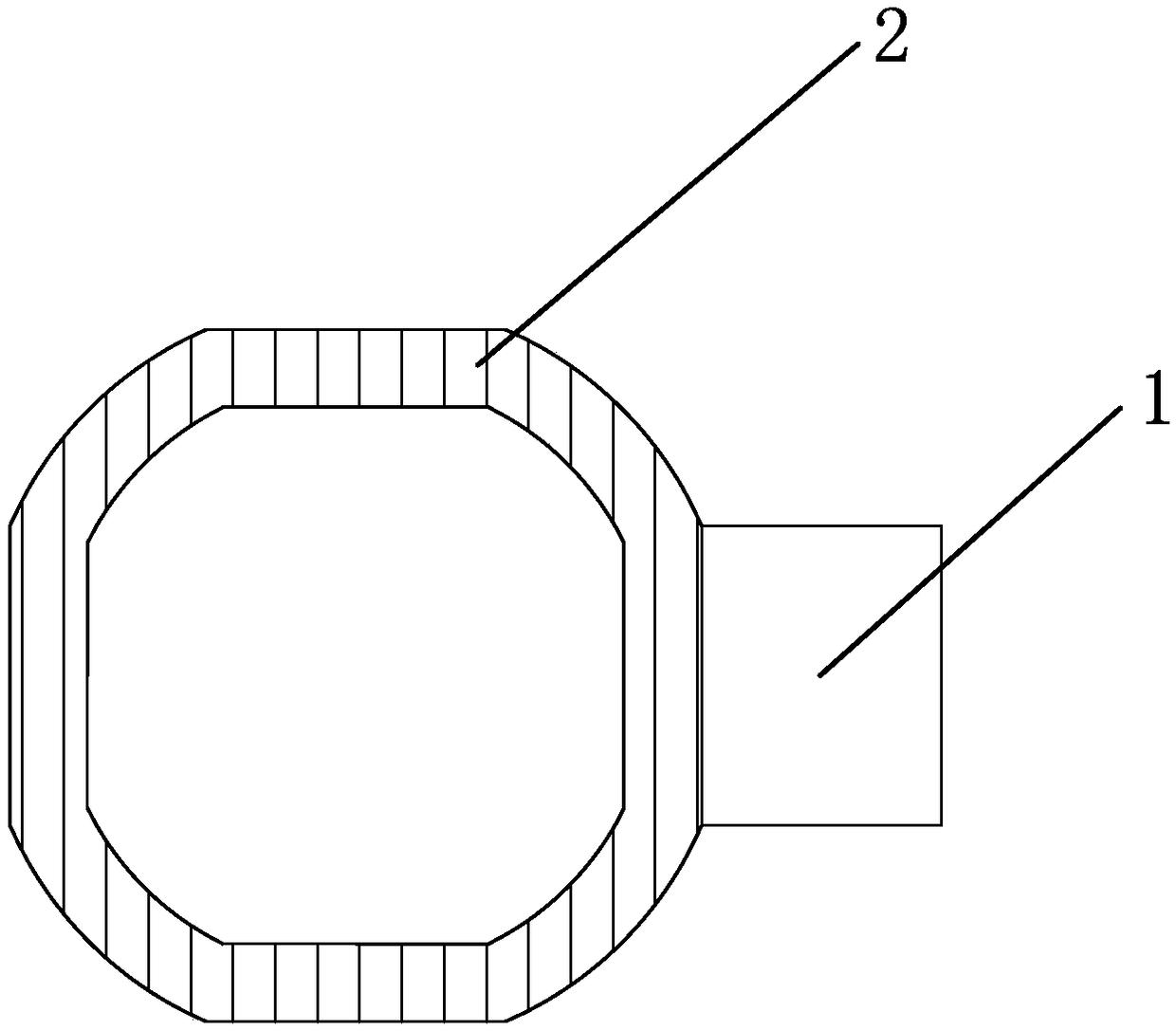

[0023] Such as Figure 1-2 As shown, a welded joint for fixing fire bellows, including pipe one and pipe two, both pipe one and pipe two are made of stainless steel, pipe one includes main body one 1, nozzle one 2 and nozzle two 3 , nozzle one 2 is perpendicular to the axis of nozzle two 3, pipe two comprises main body two 4, nozzle three 5 and nozzle four 6, the axes of nozzle three 5 and nozzle four 6 are coaxial, nozzle two 3 It is welded and fixed with nozzle three 5.

[0024] A groove 7 is opened on the outer wall of the main body 1 . The groove 7 has the advantage of being non-slip.

[0025] The nozzle 12 of the pipe 1 is provided with an external thread. Nozzle one 2 is connected with the fire sprinkler head.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com