Comprehensive error checking device and method for entering and exiting positioning gauge of tail vehicle surface of roving frame

A calibration device and comprehensive error technology, applied in the direction of mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems of increased fixed value error, impact on the quality of equipment flat cars, and inability to detect or calibrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

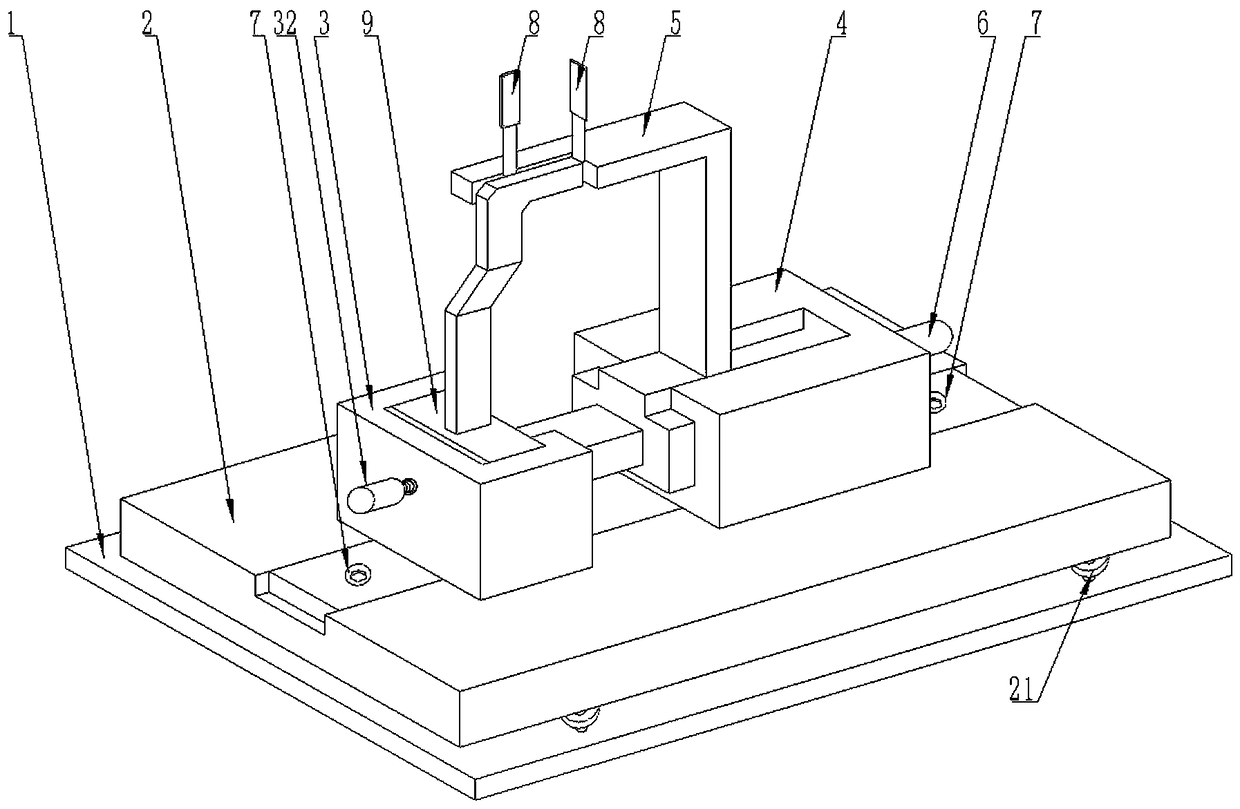

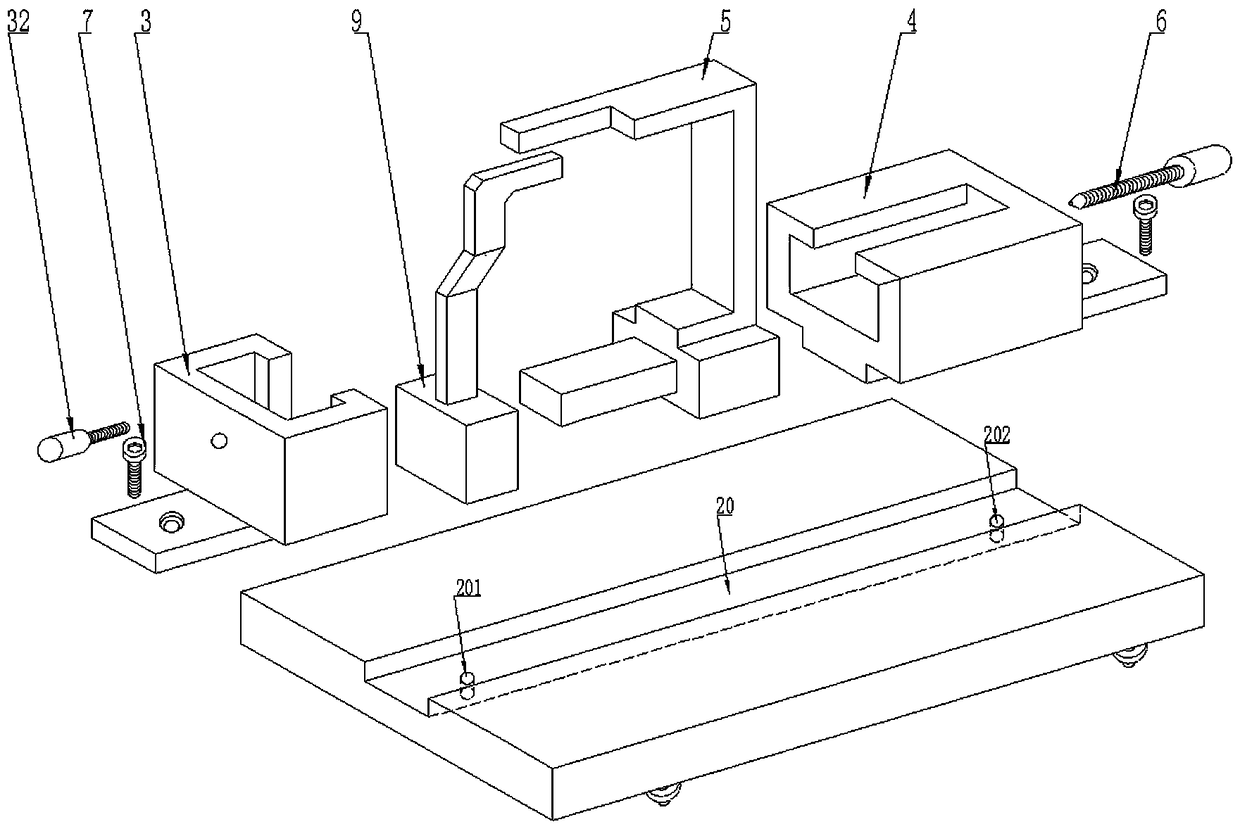

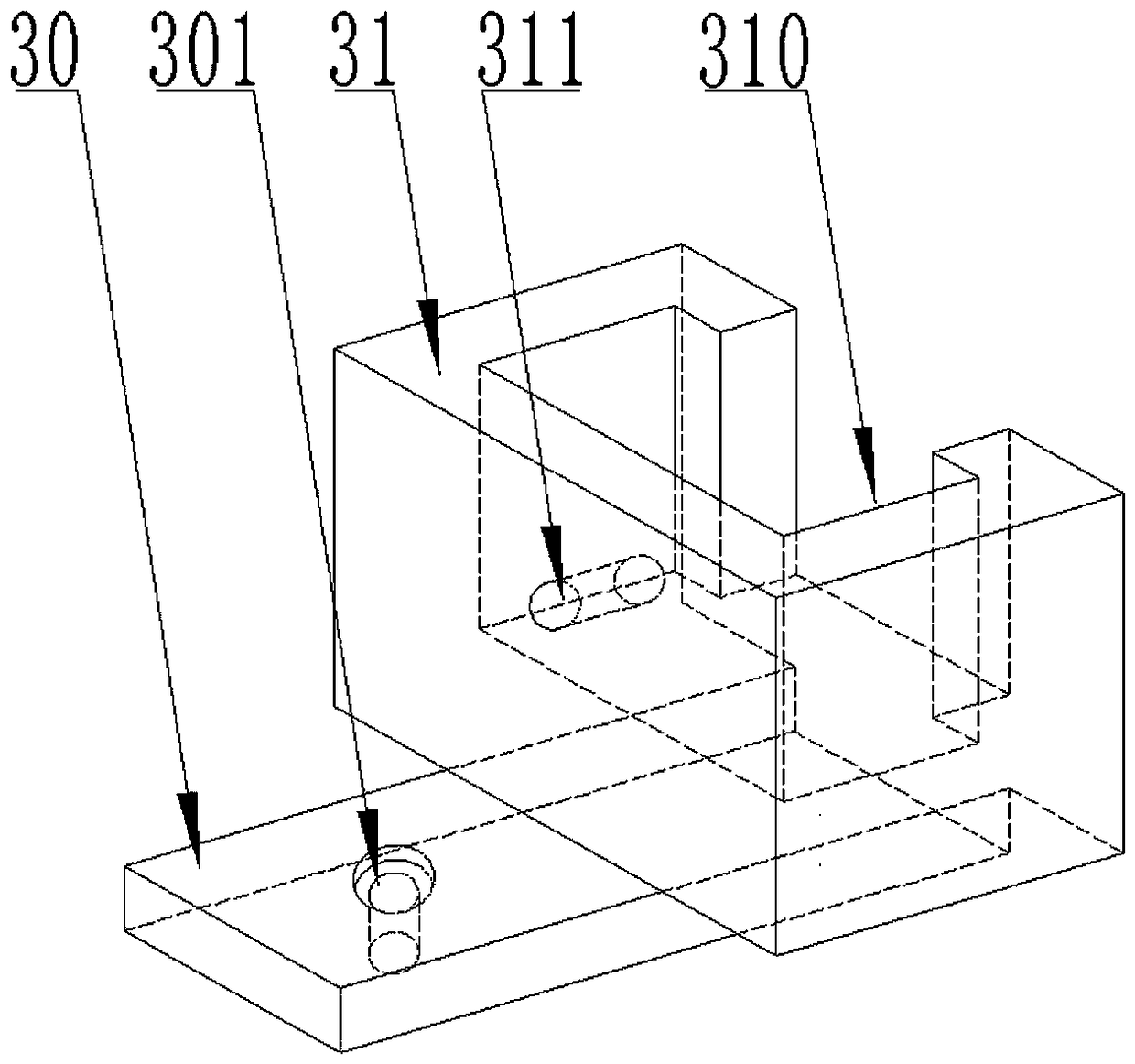

[0032] Such as Figure 1 to Figure 7 It can be seen that the comprehensive error checking device of the roving frame tail car surface entry and exit positioning gauge of the present invention includes a base 1, an adjustment platform 2 is provided on the base 1, and a groove 20 is provided on the adjustment platform 2 along the center line. The left end of described groove 20 is provided with positioning platform A3, and the right end is provided with positioning platform B4; Described positioning platform A3 comprises the slide block A30 that matches with groove 20, and described slide block A30 top is provided with bar block A31, so An opening groove 310 is arranged above the strip block A31 ; the opening groove 310 is arranged along a vertical direction, and its opening faces the center of the adjustment platform 2 .

[0033] The positioning table B4 incl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap