Fiber coating removal device, removal system, removal method and external device

A technology of external devices and optical fibers, applied in the directions of light guides, optics, optical components, etc., can solve the problems of increasing the frequency of changing heating conditions and increasing the trouble, and achieve the effect of easy setting and changing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

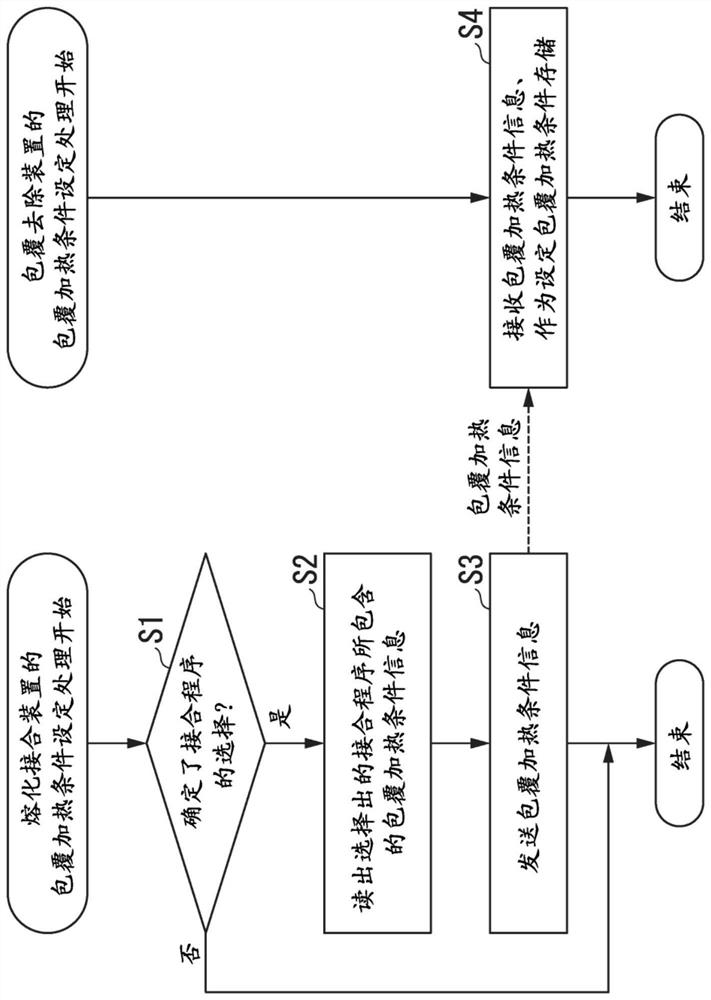

[0059] Hereinafter, an optical fiber coating removal system according to a first embodiment of the present invention will be described with reference to the drawings.

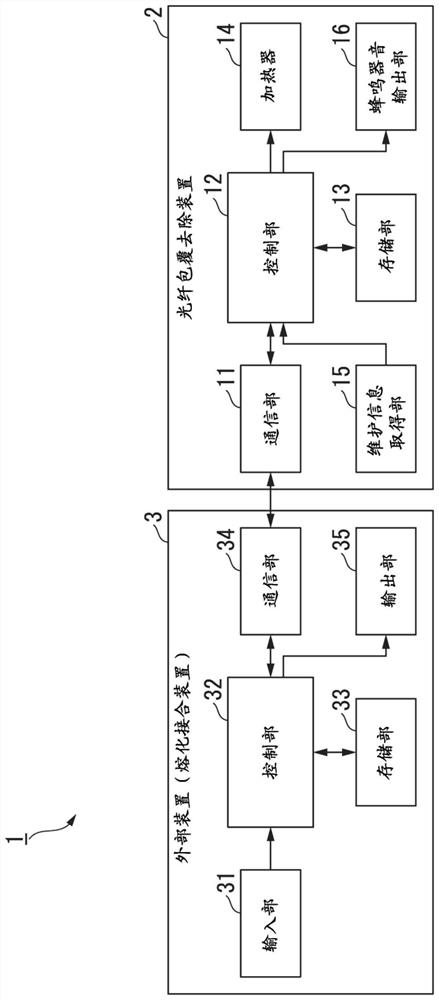

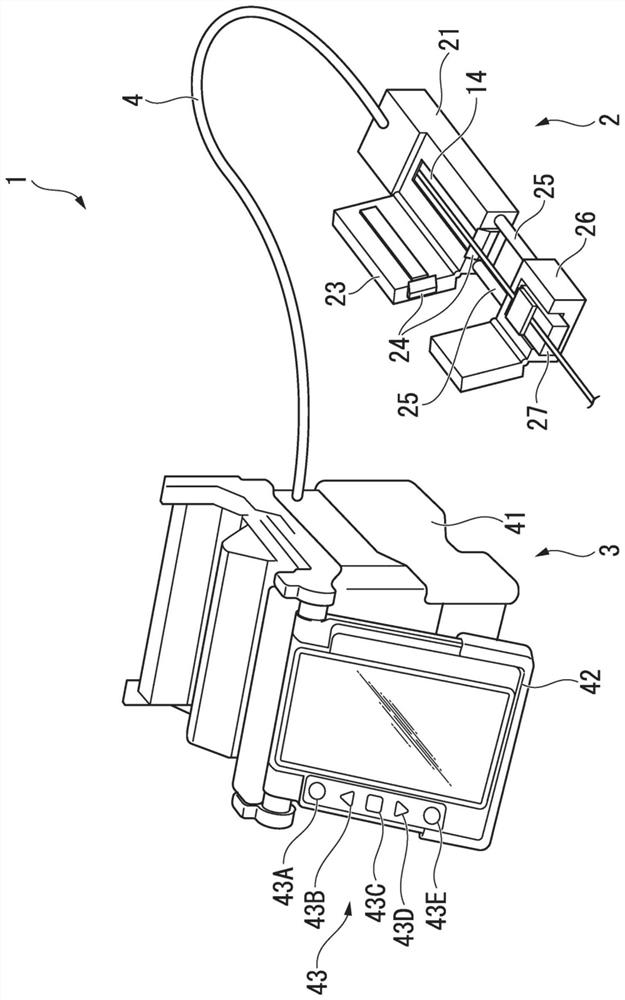

[0060] Such as figure 1 as well as figure 2 As shown, the optical fiber coating removal system 1 of the present embodiment includes an optical fiber coating removal device 2 (hereinafter, simply referred to as the coating removal device 2 ) and an external device 3 .

[0061] Such as figure 1 As shown, the coating removal device 2 includes a communication unit 11 , a control unit 12 , a storage unit 13 , a heater 14 , a maintenance information acquisition unit 15 , and a buzzer sound output unit 16 . In addition, the external device 3 is an optical fiber fusion splicing device (hereinafter, simply referred to as a fusion splicing device) that melts and splices optical fibers from which the coating at the ends has been removed. Hereinafter, the present embodiment will be described with the external device 3 ...

no. 2 approach

[0166] Next, an optical fiber coating removal system according to a second embodiment of the present invention will be described with reference to the drawings. The main difference replaced by the optical fiber coating removal system of the second embodiment is that the optical fiber coating removal system of the first embodiment is no longer a fusion splicing device, but a mobile terminal. In addition, the coating removal device 2 differs from the above-mentioned embodiment mainly in the information stored in the storage unit 13 and the control by the control unit 12 compared with the coating removal device 2 of the first embodiment. Hereinafter, the second embodiment will be described focusing on differences from the above-described embodiment. In addition, the same code|symbol is attached|subjected to the common member and element in some cases, and the description is abbreviate|omitted.

[0167] Such as Figure 21 As shown, the optical fiber coating removal system 5 incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com