Iron-chromium flow battery

A technology of flow battery and chromium solution, applied in the field of iron-chromium flow battery, can solve the problems of large degree of side reaction, and the performance and capacity of flow battery are not particularly good, and achieve the effect of improving performance and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

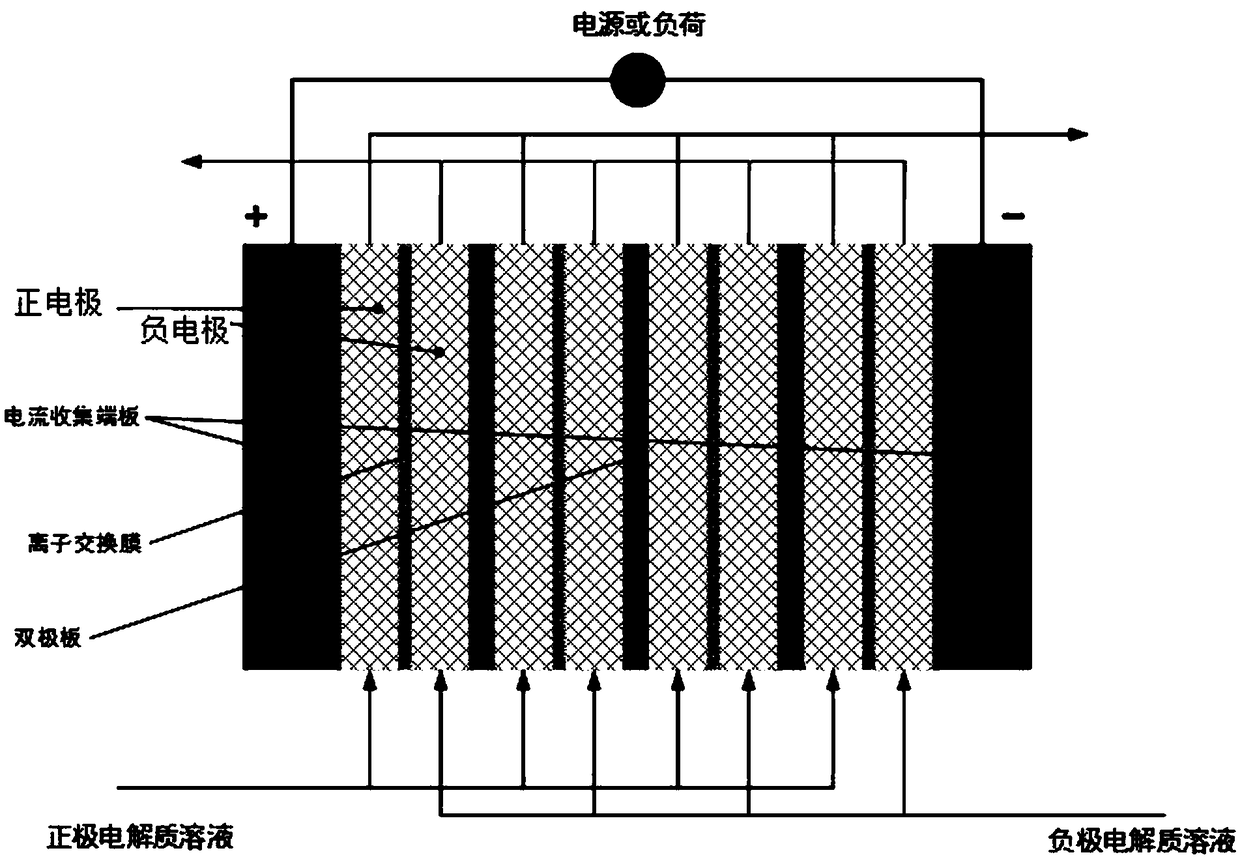

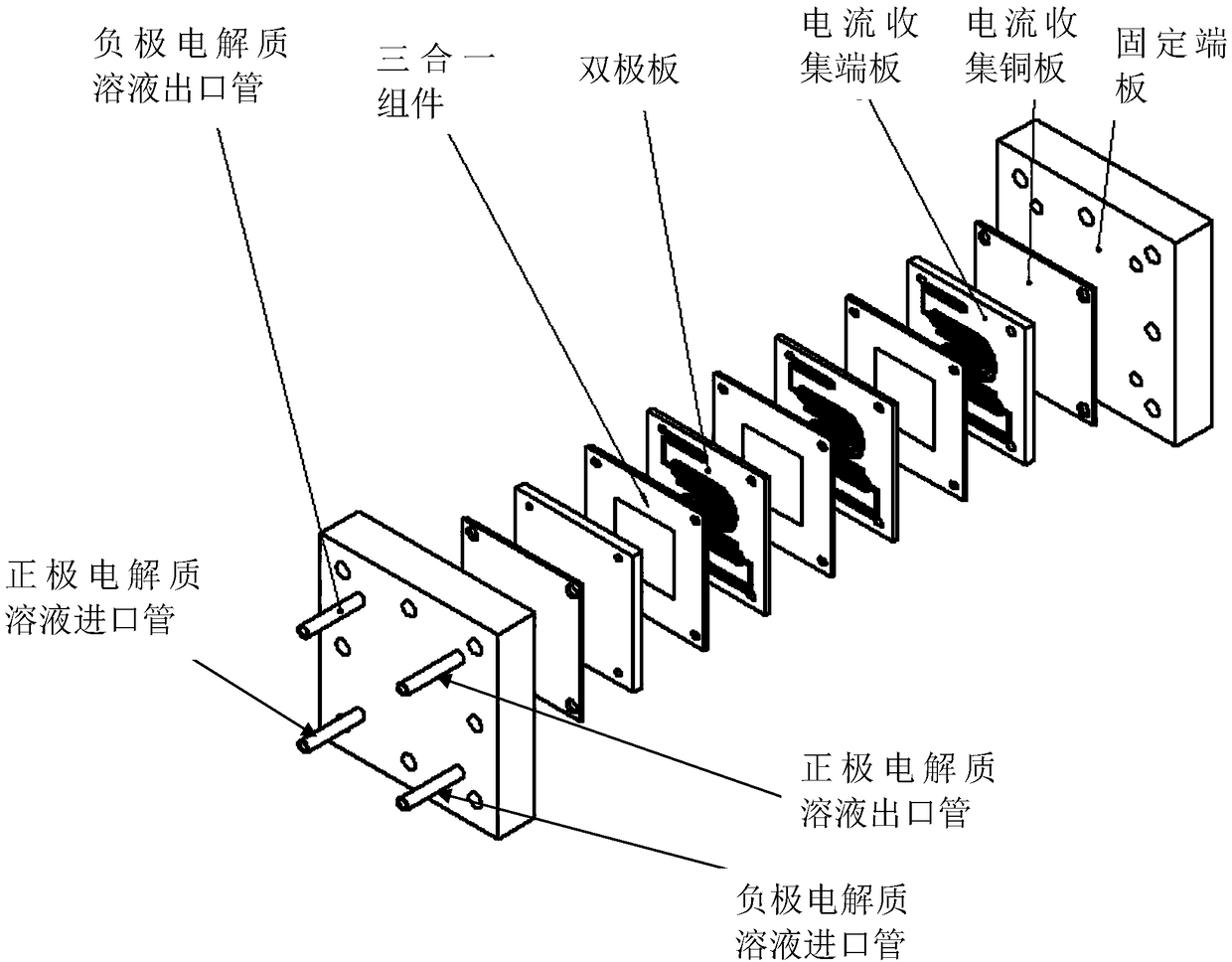

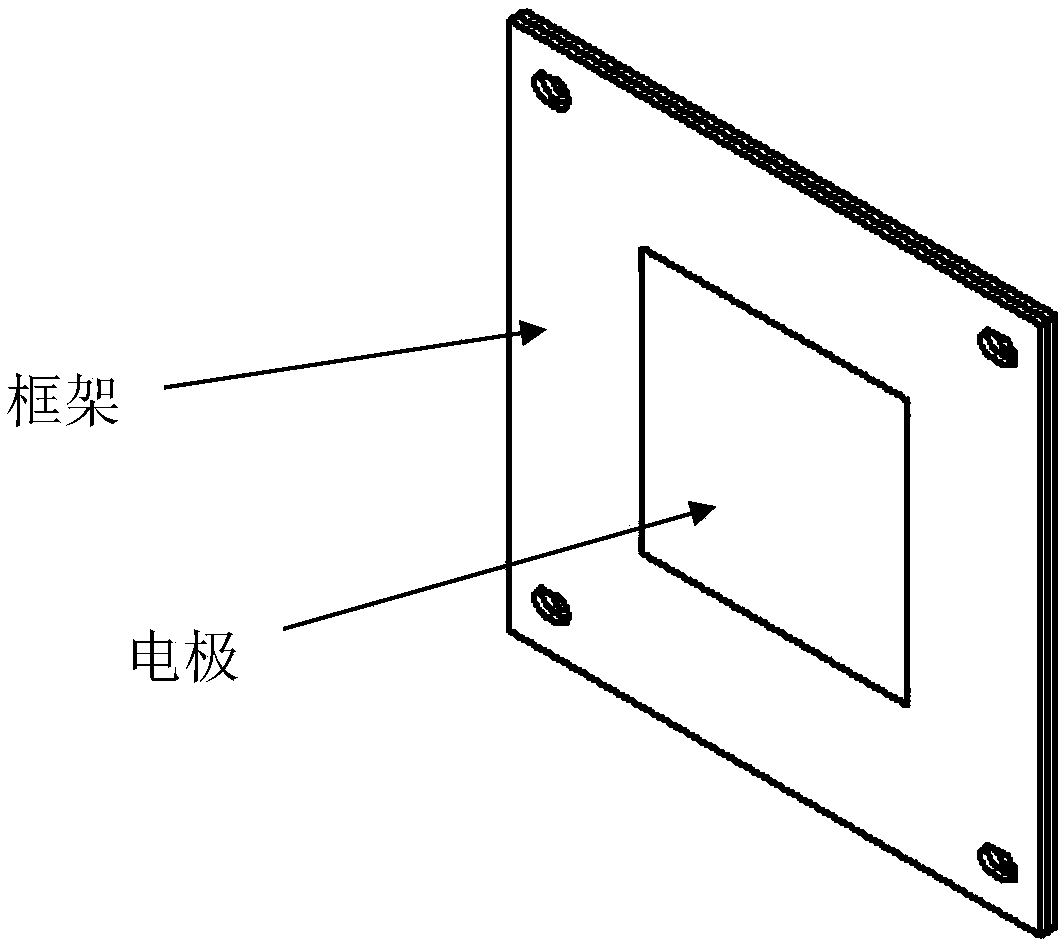

[0022] Such as Figures 1 to 5 As shown, the present invention preferably prefers an iron-chromium flow battery, such as figure 2 As shown, the iron-chromium flow battery includes a three-in-one component, a current collecting end plate, a bipolar plate, a current collecting copper plate, and a fixed end plate. The bipolar plate is sandwiched between the three-in-one component, and the three-in-one The component is attached with a current collecting end plate, and the fixed end plate is located at both ends of the iron-chromium flow battery to fix the three-in-one component, the current collecting end plate, the bipolar plate, and the current collecting copper plate, and the current collecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus of elasticity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com