Liquid distributing device

A liquid separation and light liquid technology, which is applied in the direction of separation methods, liquid separation, liquid separation auxiliary equipment, etc., can solve the problem that the purity of liquid separation cannot meet the high purity requirements of industrial production, and achieve the convenience of large-scale promotion and use and equipment assembly The effect of low cost and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

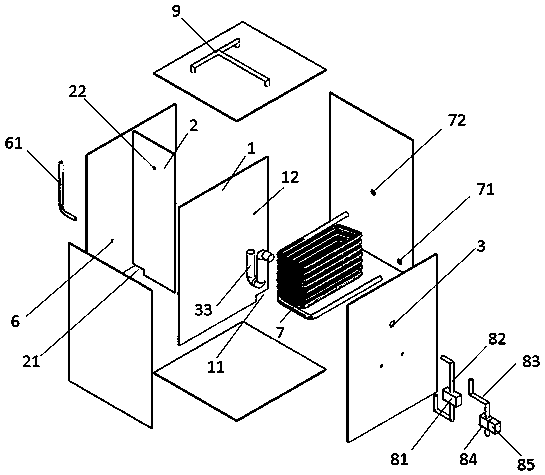

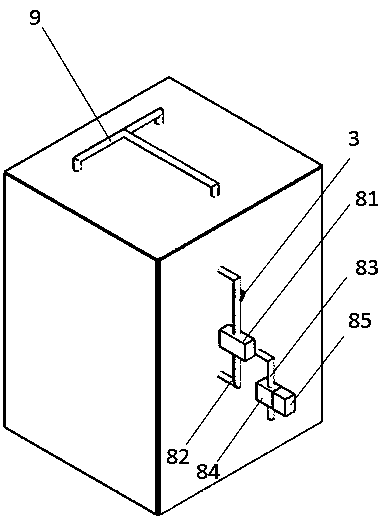

[0029] As shown in the figure, the present invention discloses a liquid dispensing device.

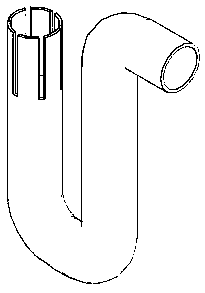

[0030] Specifically, a liquid separation device includes a liquid separation mechanism, a liquid cooling mechanism, a liquid level sensing mechanism, a light liquid discharge mechanism, a heavy liquid discharge mechanism, and a pressure balance mechanism. The liquid separation mechanism includes a box, a first The partition 1 and the second partition 2, the first partition 1 and the second partition 2 are fixedly arranged inside the box in a T-shape and divide the box into a primary separation chamber, two A first-stage separation chamber and a third-stage separation chamber; the side wall of the first-stage separation chamber is provided with a mixed liquid inlet 3, a cooling liquid inlet 71, and a cooling liquid outlet 72, and a U-shaped pipe 33 is sleeved on the mixed liquid inlet 3; A heavy liquid outlet 6 is provided on the side wall of the tertiary tank.

[0031] The mixed liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com