Efficient ultrasonic cleaning machine

A technology of ultrasonic waves and cleaning machines, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as poor tolerance of cleaning parts, poor heating uniformity, and affecting cleaning effects, etc., to avoid The effect of cleaning dead corners, increasing the size range, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

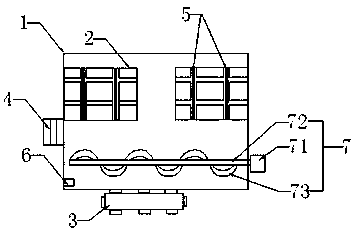

[0020] A high-efficiency ultrasonic cleaning machine, comprising: a cleaning tank 1, a cleaning grid 2, an ultrasonic generator 3, an ultrasonic transducer 4, a heating device 5, a temperature sensor 6 and a controller.

[0021] Wherein, the ultrasonic generator 3 is installed outside the bottom of the cleaning tank 1 , and the ultrasonic transducer 4 is installed on the outer side wall of the cleaning tank 1 and is electrically connected with the ultrasonic generator 3 .

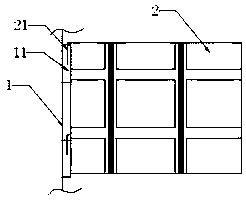

[0022] There are two cleaning racks 2, which are respectively installed on the inner walls of the opposite sides of the cleaning tank 1, that is, one side of each cleaning rack 2 is respectively installed on the inner wall of the corresponding cleaning tank 1. Specifically, the four corners of the side wall of the cleaning grid 2 facing the corresponding side of the cleaning tank are respectively equipped with uprights 21, and the side walls of the cleaning tank are correspondingly equipped with annular slee...

Embodiment 2

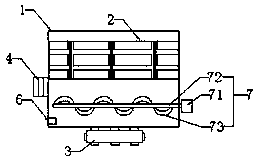

[0026] Please refer to the attached image 3 . The difference from Embodiment 1 is that there is only one cleaning rack 2, and the two ends thereof are respectively installed on the side walls of the cleaning tank 1 on opposite sides. The two ends of the cleaning rack 2 are respectively equipped with columns 21 at one side and four corners of the side wall of the cleaning tank on the corresponding side. The side walls of the cleaning tank are correspondingly equipped with annular sleeves 11, and the columns 21 are inserted and connected to the ring Inside set 11. The fixing between the cleaning grid frame 2 and the cleaning tank 1 is realized. When the size of the cleaning piece is large, install one of the above-mentioned cleaning grids in the cleaning tank, and place the cleaning pieces in the cleaning grid for cleaning. The advantage of installing such a large-size cleaning rack with both ends fixed in the cleaning tank to hold the cleaning parts is that the large-size c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com