Ball cage retainer locating clamp for broaching machine

A technology for positioning fixtures and cages, which is applied to broaching machines, broaching machines, manufacturing tools, etc., can solve the problems of inaccurate positioning, inability to ensure broaching accuracy, and troublesome positioning of positioning fixtures, and achieve easy operation methods and simple structures. , easy to grasp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

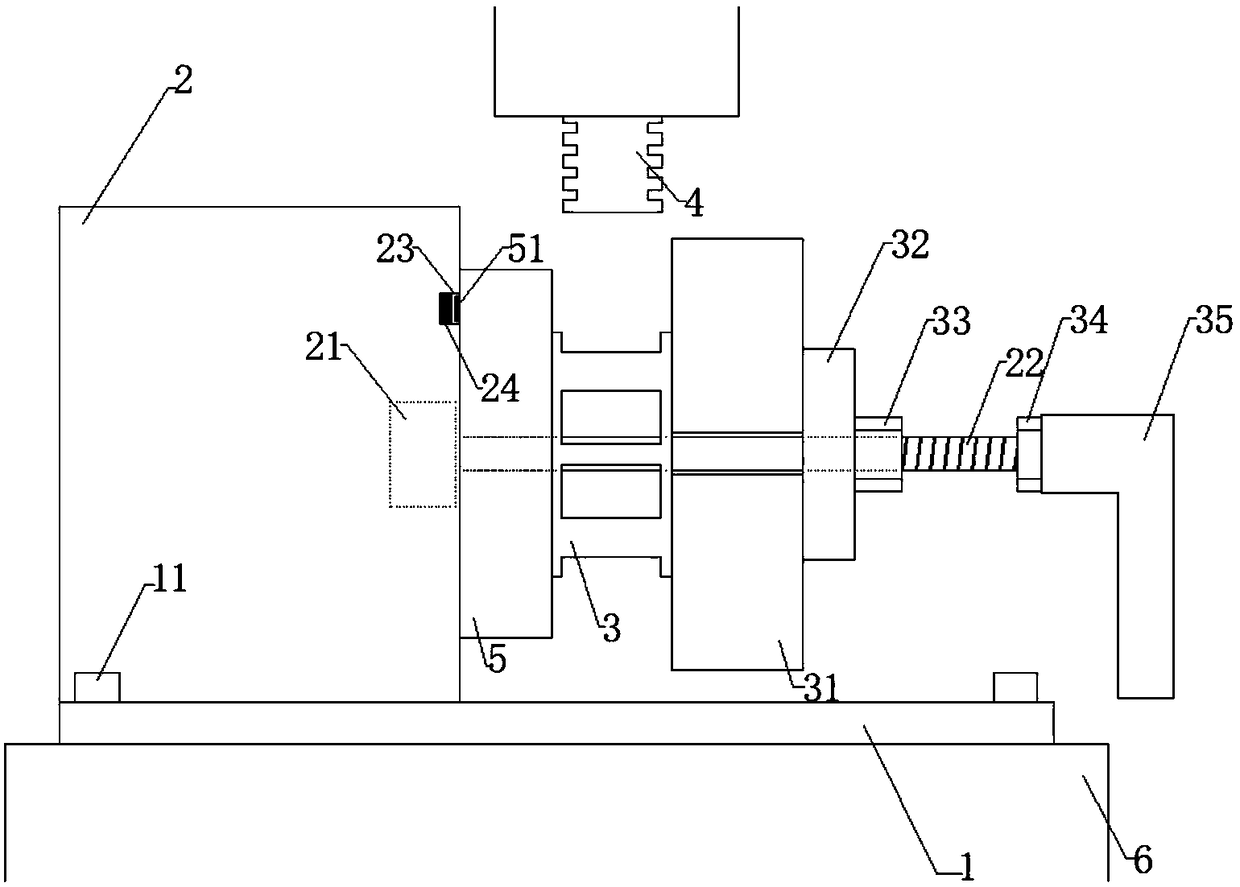

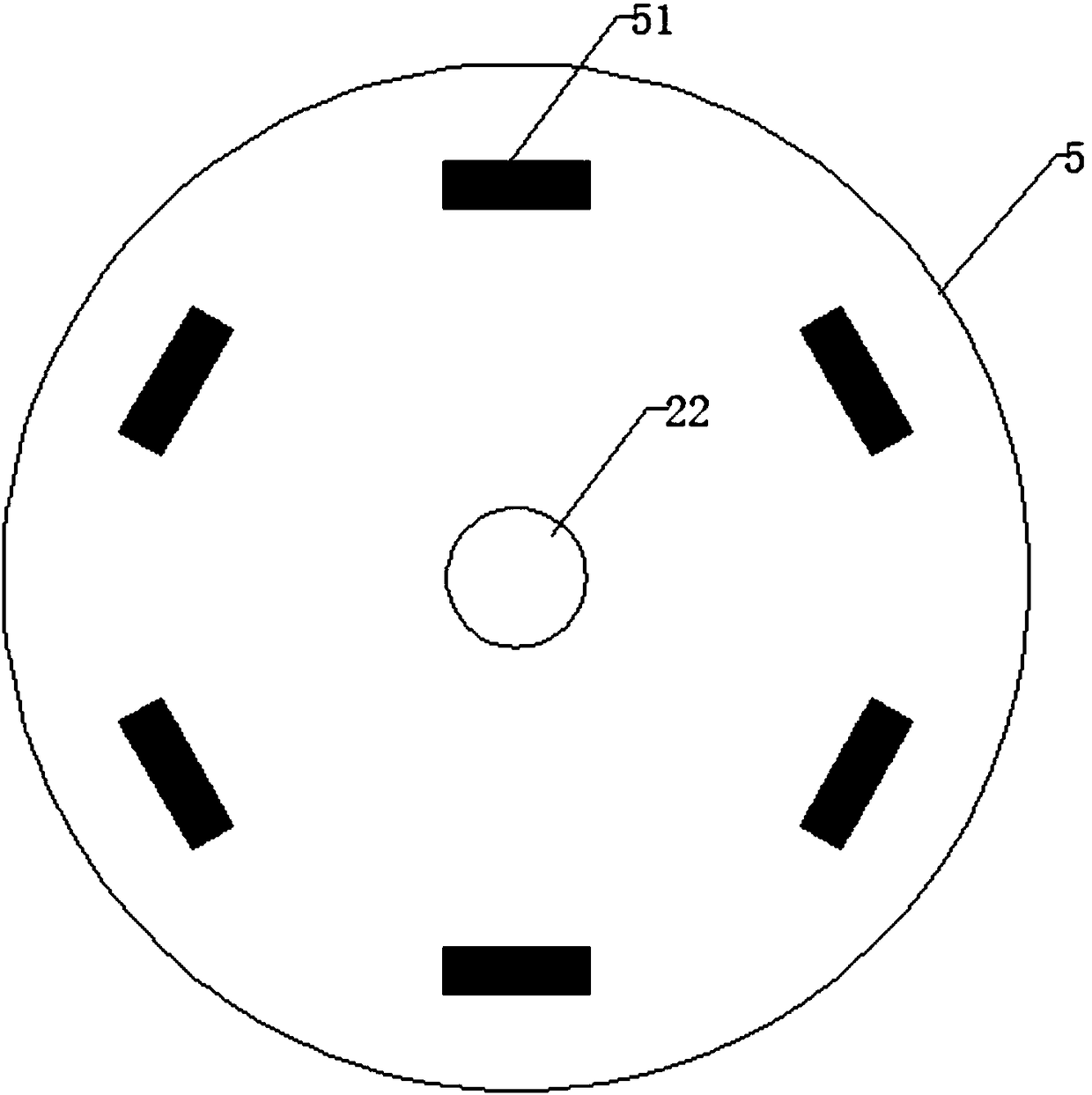

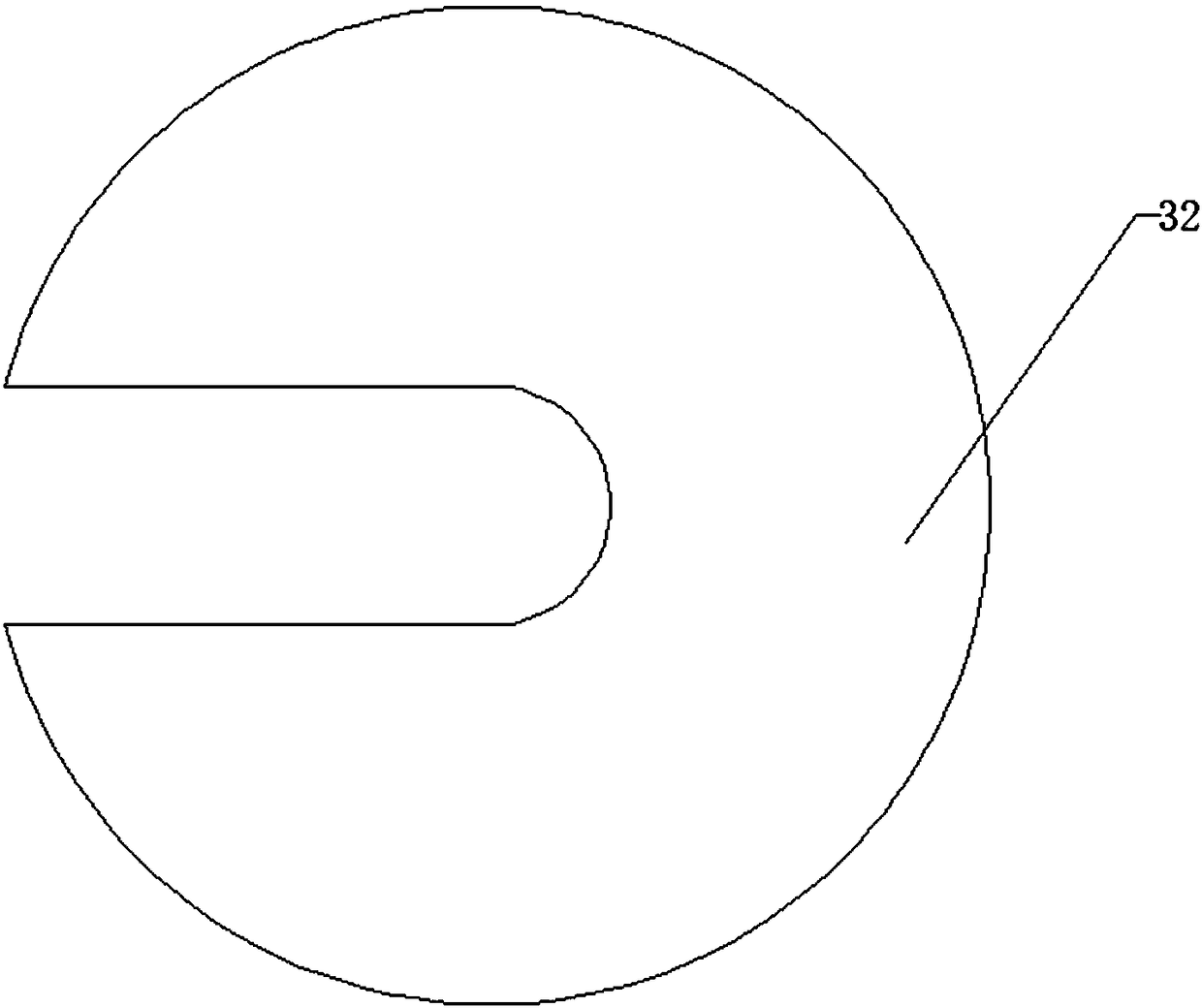

[0013] Such as figure 1 , 2 , 3, 4, and 5, a positioning fixture for a cage cage for a broaching machine is characterized in that it includes a fixing plate 1, and the fixing plate 1 is fixed on the operating table 9 of the broaching machine through positioning bolts 11, Bearing fixing seat 2, fixed positioning block 5, cage bearing part 3, movable positioning block 31, gasket 32, compression nut 33, linkage bolt 34 and inner hexagon socket 35 are arranged on the fixed plate 1 in sequence from left to right. Above, the bearing fixing seat 2 is welded on the fixing plate 1, the bearing fixing seat 2 is provided with a bearing 21, the bearing 21 is connected with the screw rod 22 of the interlocking bolt 34, and the left limit block 5 is a cylindrical structure and its surface is welded in two The clamping block 51 with an angle of 60 degrees, the end of the clamping block 51 is provided with a spring 52, which is a triangular prism iron structure and the number is six. The bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com