Oil supporting positioning device for machining of thin-walled spherical workpiece

A support positioning and spherical technology, which is applied in the direction of positioning devices, grinding workpiece supports, metal processing equipment, etc., can solve the problems of unfavorable inner and outer spherical surface finishing, lower processing quality, workpiece deformation, etc., so as to avoid workpiece deformation and improve quality , the effect of absorbing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

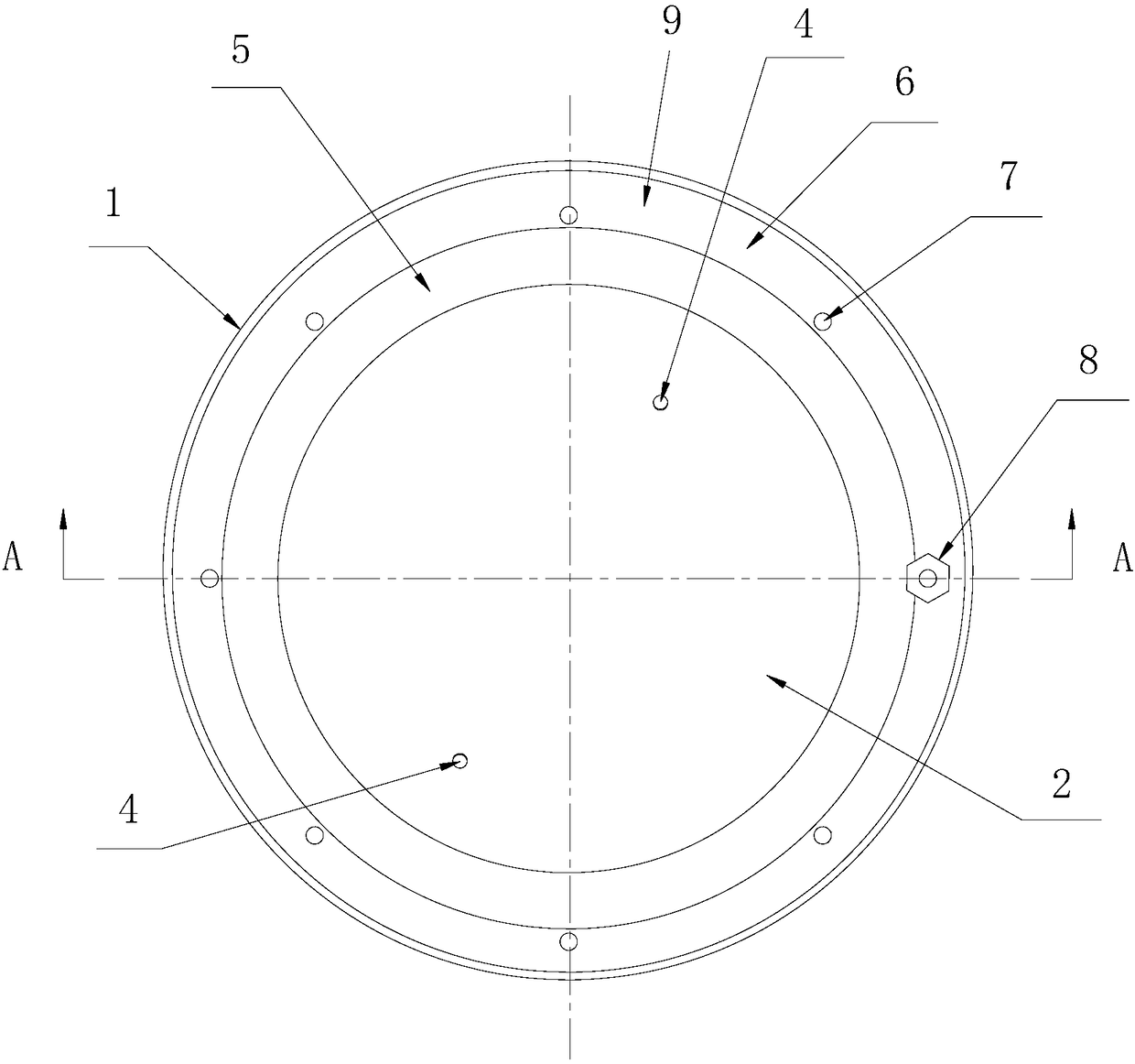

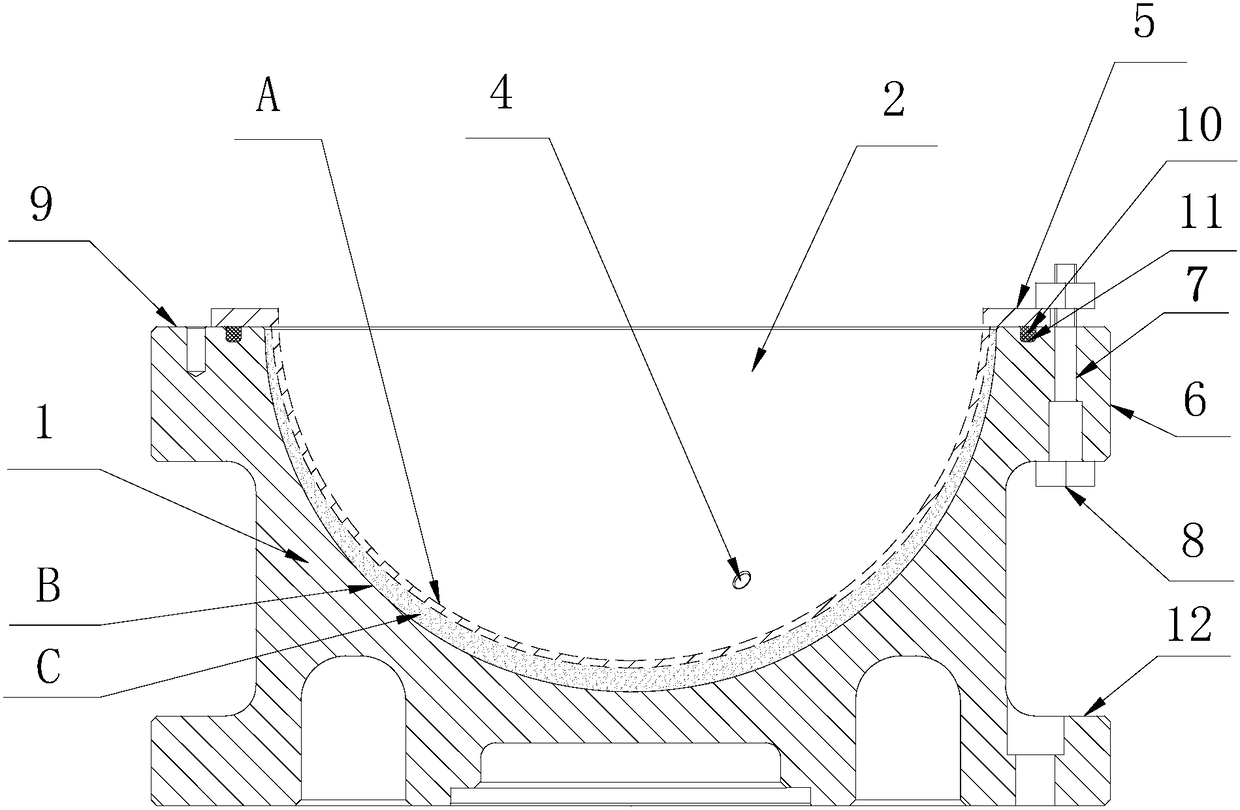

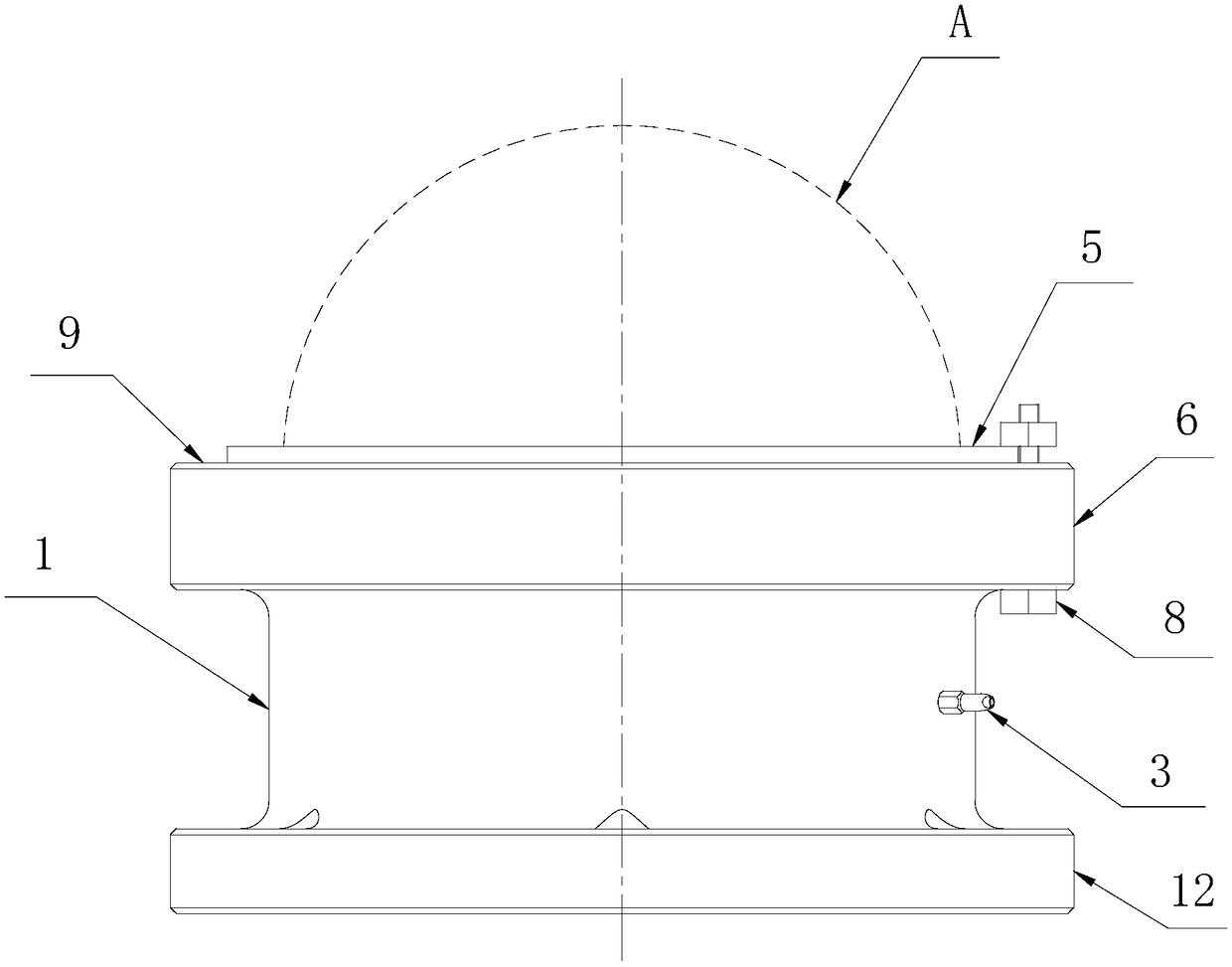

[0024] Example: Combining Figure 1~Figure 3 The specific implementation of the grease supporting and positioning device for processing thin-walled spherical workpieces provided by the present invention is described as follows: it has a support base 1, an annular pressure plate 5 and a sealing ring 10, and the top of the support base 1 has a table 9. The table 9 is provided with a hemispherical groove 2 for the thin-walled spherical workpiece A to be embedded, and the outer wall of the support base 1 is provided with an oil injection nozzle 3, and the inner wall of the hemispherical groove 2 is provided with an oil injection hole 4 communicating with the oil injection nozzle 3. In this embodiment, the number of the oil injection holes 4 is two, and they are all connected to the oil injection nozzle 3 via an oil pipeline provided inside the support base 1. And the two oil injection holes 4 are distributed symmetrically about the center of the hemispherical groove 2, such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com