Hanging connecting structure of power battery box body and universal mounting method thereof

A technology of power battery and connection structure, applied in the direction of power unit, electric power unit, transportation and packaging, etc., can solve the problems of inability to install directly, unstable installation, difficult adjustment of installation error, etc., to increase connection and local strength, installation The effect of high strength and strong installation versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but the present invention is not limited to the following specific embodiments.

[0045] "Front" and "rear" in the present invention refer to the X direction of the vehicle, that is, the longitudinal direction of the vehicle. The "first", "second", "third", "fourth" and "fifth" mentioned in the present invention are only to distinguish and describe each component, and there is no distinction of importance or order.

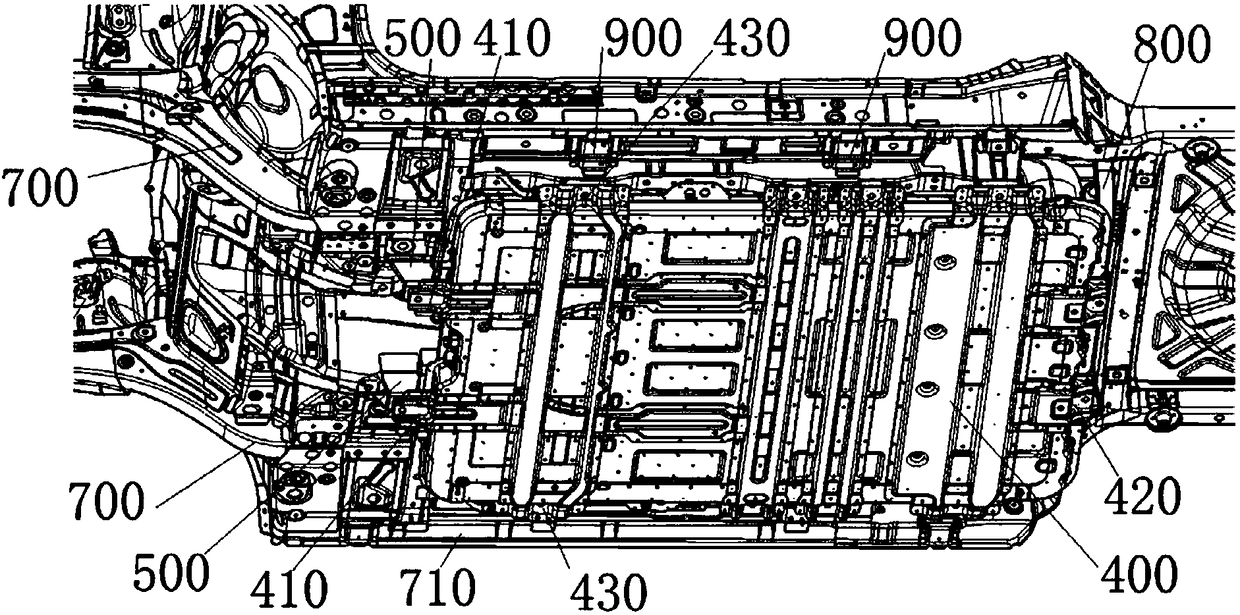

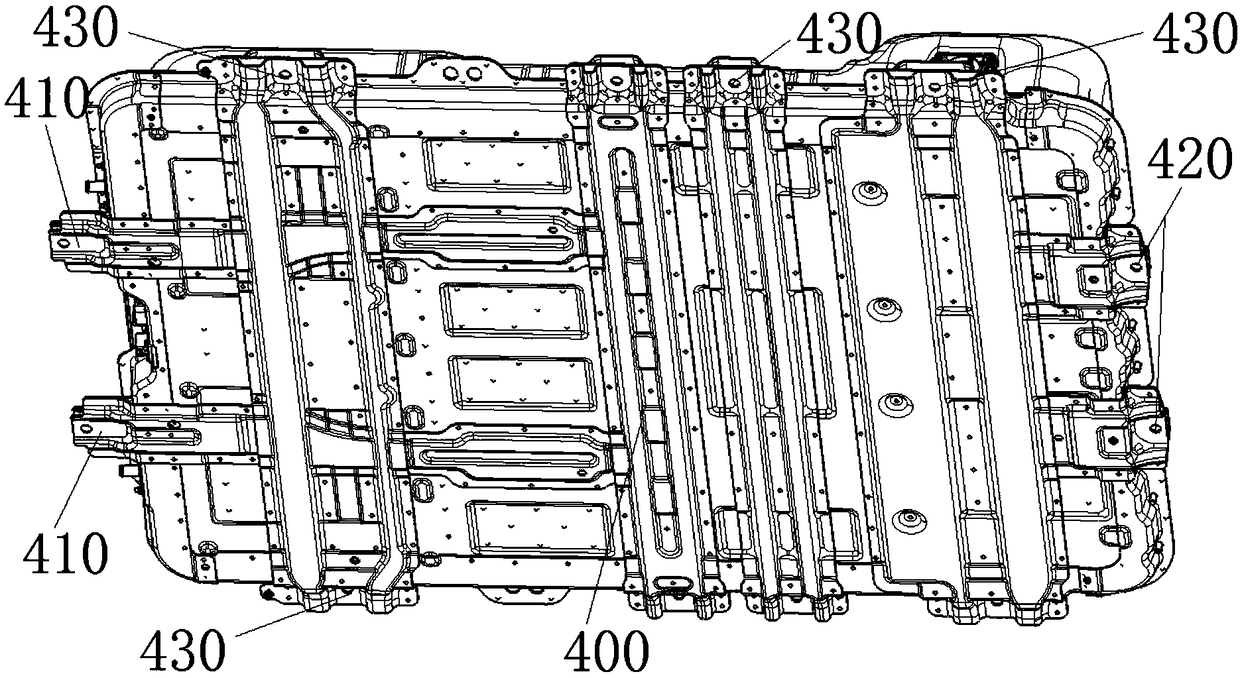

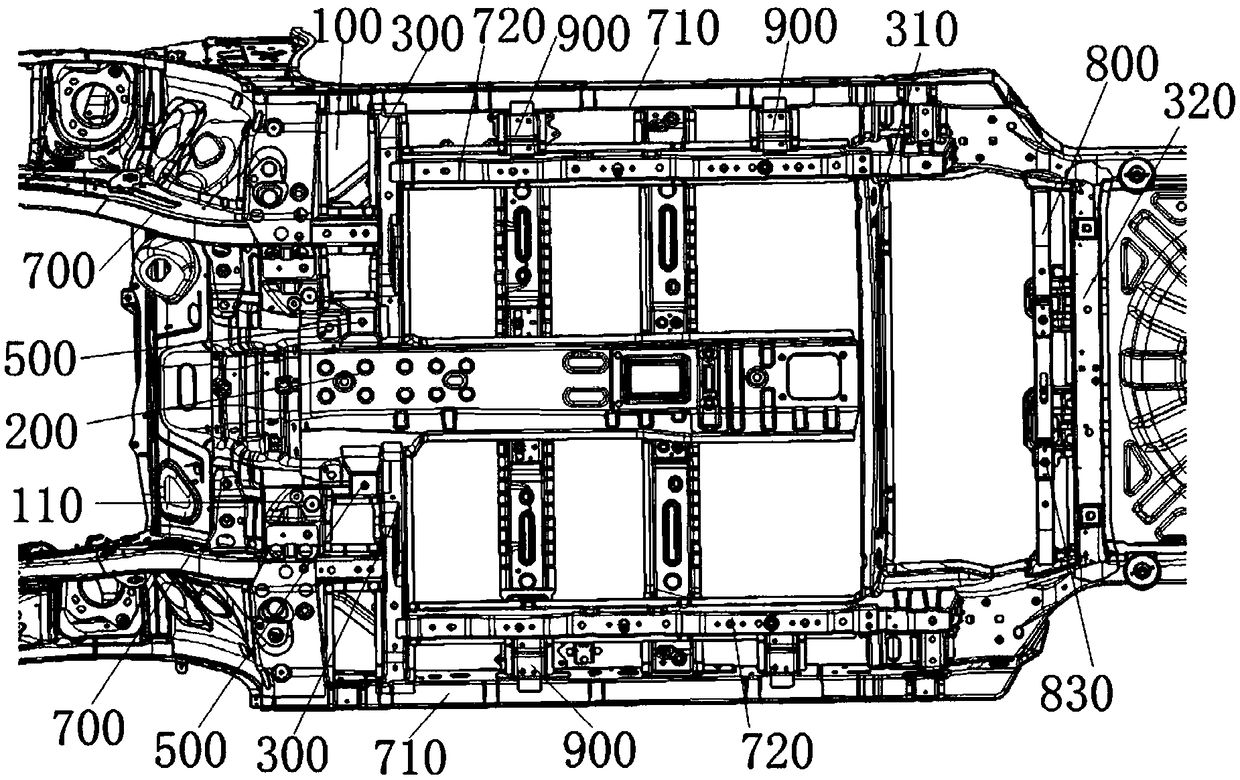

[0046] like figure 2 and Figure 8 As shown, the power battery box 400 of the present invention is an integrated body of a modular power battery and an external box, and the power battery box 400 of the present invention is based on the same modular model of the power battery box The installation of the 400 on the car floor enables the power battery box 400 to be installed on pure el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com