Amorphous strip back-roll equipment

A technology of rewinding and rewinding of amorphous strips, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problem that the tension control accuracy needs to be further improved, the rewinding tension cannot be guaranteed, and the structure of rewinding equipment is complex, etc. problems, achieve the effect of realizing automatic deviation correction of wrong layers, increasing operation flexibility and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

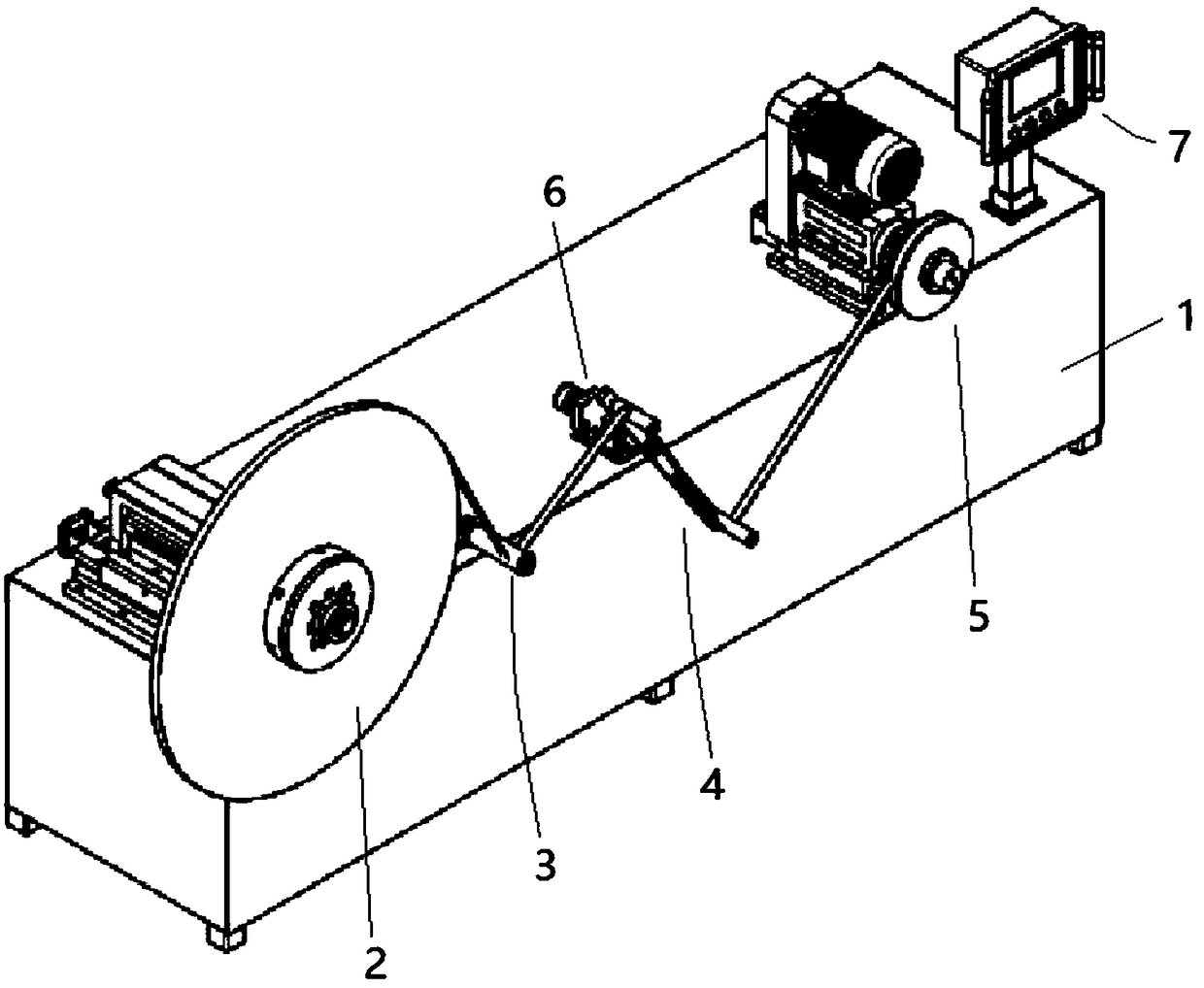

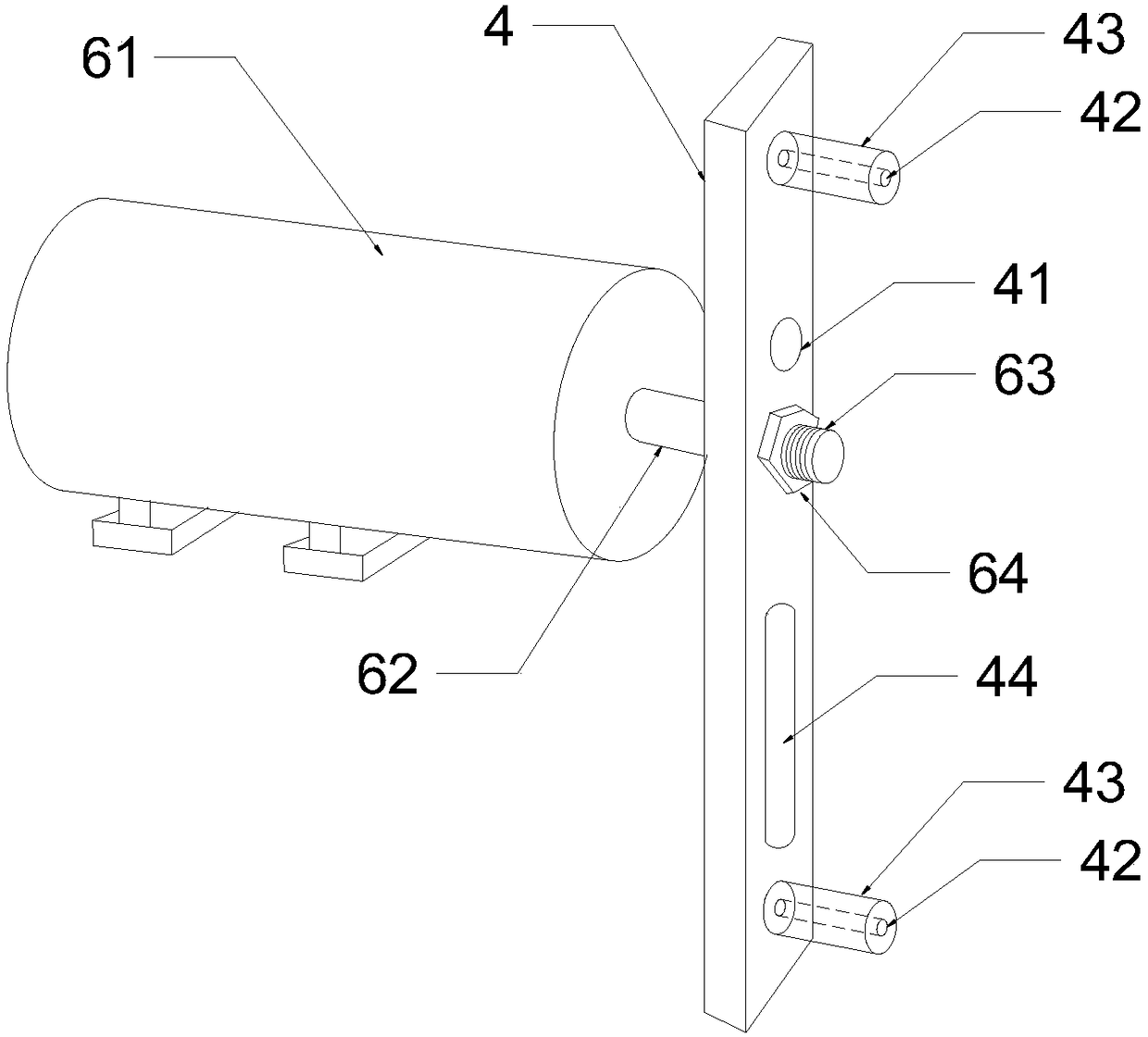

[0027] Such as figure 1 and figure 2 As shown, a rewinding device for an amorphous strip includes a frame 1, on which an unwinding system 2, a pressure roller 3, a swing rod 4 and a winding system 5 are sequentially arranged, and on the frame 1 there is also a There is a PLC controller; the large roll of amorphous strip formed after smelting and quenching passes through the unwinding system 2, the pressure roller 3, the swing rod 4 and the winding system 5 in turn, and forms a small roll of amorphous strip after rewinding , so that it is easy to pack into finished amorphous strips of specifications required by customers. The unwinding system 2 is used to transfer the amorphous strips to the pressure roller 3. The unwinding system 2 includes: unwinding frequency conversion motor, unwinding encoder and The unwinding frequency converter, the unwinding variable frequency motor is connected to the unwinding encoder, and the unwinding encoder is connected to the unwinding frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com