Halogen-free, low-smoke and flame-retardant cable material and processing technology thereof

A low-smoke flame-retardant, cable material technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of suffocation, fuel fire, loss, etc., and achieve the effect of not easy to smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

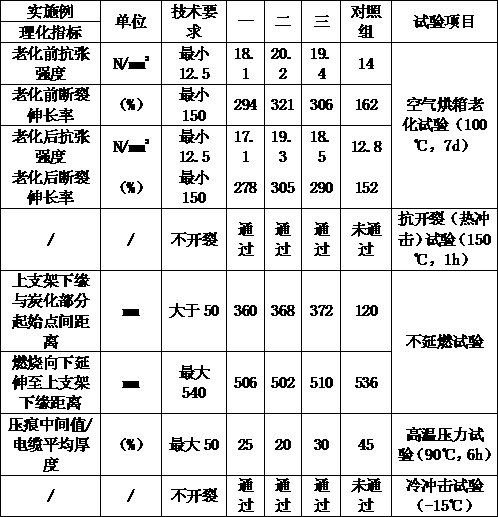

Examples

Embodiment 1

[0017] A halogen-free low-smoke flame-retardant cable material, made of the following raw materials in parts by weight: 40 parts of high-density polyethylene, 30 parts of low-density polyethylene, 20 parts of butadiene rubber particles, sufficient hydrogen peroxide, flame retardant 1 part, 2 parts of tonic.

[0018] A kind of above-mentioned halogen-free low-smoke flame-retardant cable material, its processing technology comprises the following steps:

[0019] (1) Mix the high-density polyethylene and low-density polyethylene in the formula amount evenly, add enough hydrogen peroxide to cause a cross-linking reaction, and then place the mixed solution in the air, and after the hydrogen peroxide is decomposed by light, Evaporate excess water again to obtain the modified mixture for subsequent use;

[0020] (2) Add the modified mixture obtained in step 1 to the formula amount of butadiene rubber particles, flame retardant and reinforcing agent, put it into a pulverizer for crus...

Embodiment 2

[0024] A halogen-free low-smoke flame-retardant cable material, which is made of the following raw materials in parts by weight: 40-60 parts of high-density polyethylene, 40 parts of low-density polyethylene, 25 parts of butadiene rubber particles, sufficient hydrogen peroxide, and 1.5 parts of fuel, 3 parts of reinforcing agent.

[0025] A kind of above-mentioned halogen-free low-smoke flame-retardant cable material, its processing technology comprises the following steps:

[0026] (1) Mix the high-density polyethylene and low-density polyethylene in the formula amount evenly, add enough hydrogen peroxide to cause a cross-linking reaction, and then place the mixed solution in the air, and after the hydrogen peroxide is decomposed by light, Evaporate excess water again to obtain the modified mixture for subsequent use;

[0027] (2) Add the modified mixture obtained in step 1 to the formula amount of butadiene rubber particles, flame retardant and reinforcing agent, put it int...

Embodiment 3

[0031] A halogen-free low-smoke flame-retardant cable material, made of the following raw materials in parts by weight: 60 parts of high-density polyethylene, 50 parts of low-density polyethylene, 30 parts of butadiene rubber particles, sufficient hydrogen peroxide, flame retardant 2 parts, 4 parts of strengthening agent.

[0032] A kind of above-mentioned halogen-free low-smoke flame-retardant cable material, its processing technology comprises the following steps:

[0033] (1) Mix the high-density polyethylene and low-density polyethylene in the formula amount evenly, add enough hydrogen peroxide to cause a cross-linking reaction, and then place the mixed solution in the air, and after the hydrogen peroxide is decomposed by light, Evaporate excess water again to obtain the modified mixture for subsequent use;

[0034] (2) Add the modified mixture obtained in step 1 to the formula amount of butadiene rubber particles, flame retardant and reinforcing agent, put it into a pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com