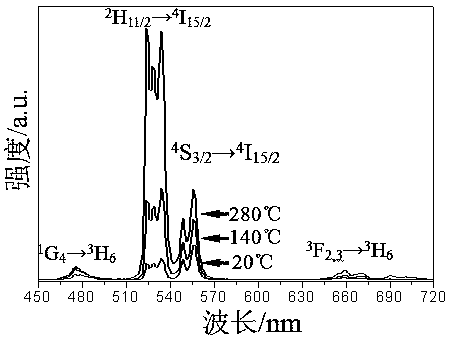

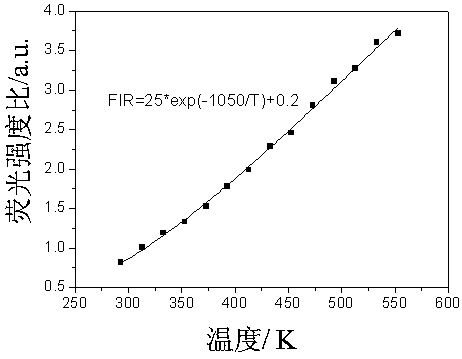

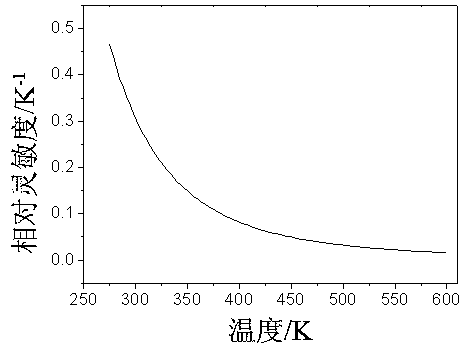

Upconversion fluorescence type core-shell nanocrystalline and preparation method and application thereof

A nanocrystalline and fluorescent technology, applied in the field of material science, can solve problems such as large temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 8mmol of Brig-58, 6.4ml of n-butanol and 40ml of cyclohexane into the flask respectively, place in a 50°C water bath and stir evenly with magnetic force to obtain a colorless transparent reverse micellar system for future use. 5ml of BaCl with a concentration of 1 mol / L 2 The solution was added dropwise into the prepared reverse micelles system, and after stirring in a water bath at 50°C for 1 hour, BaCl was obtained 2 Microemulsion. In the same way, configure 10mlEr(NO 3 ) 3 , 10ml Yb(NO 3 ) 3 , 10ml Tm(NO 3 ) 3 , 70ml Gd(NO 3 ) 3 , 140ml Na 2 MoO 4 Microemulsion. 31.169ml BaCl 2 Microemulsion, 62.337ml Gd(NO 3 ) 3 microemulsion with 124.674 ml Na 2 MoO 4 After the microemulsion was mixed, 0.165 ml Er(NO 3 ) 3 , 1.65 ml Yb (NO 3 ) 3 and 16.5 μl Tm(NO 3 ) 3 Microemulsion, stirred at room temperature for 2 hours to form a white suspension; use propanol and absolute ethanol to sonicate, wash and centrifuge three times to obtain a precipitate, dry...

Embodiment 2

[0026] Add 8mmol of Brig-58, 6.4ml of n-butanol and 40ml of cyclohexane into the flask respectively, place in a 50°C water bath and stir evenly with magnetic force to obtain a colorless transparent reverse micellar system for future use. 5ml of BaCl with a concentration of 1 mol / L 2 The solution was dropped into the configured reverse micelles drop by drop, and BaCl was obtained after stirring in a water bath at 50°C for 1 h. 2 Microemulsion. In the same way, configure 10ml Er(NO 3 ) 3 , 10ml Yb(NO 3 ) 3 , 10ml Tm(NO 3 ) 3 , 70ml Gd(NO 3 ) 3 , 130ml Na 2 MoO 4 Microemulsion. 31.68 mlBaCl 2 Microemulsion, 63.36 ml Gd(NO 3 ) 3 Microemulsion with 126.72ml Na 2 MoO 4 After the microemulsion was mixed, 0.165ml Er(NO 3 ) 3 , 0.99 ml Yb (NO 3 ) 3 and 0.165ml Tm(NO 3 ) 3 Microemulsion, stirred at room temperature for 2 hours to form a white suspension; use propanol and absolute ethanol to sonicate, wash, and centrifuge three times to obtain a precipitate, dry at ...

Embodiment 3

[0029] Add 10.6 mmol of Brig-58, 7 ml of n-butanol and 53 ml of cyclohexane into the flask respectively, place in a water bath at 50°C and stir evenly with magnetic force to obtain a colorless transparent reverse micellar system for future use. 5ml of BaCl with a concentration of 1 mol / L 2 The solution was dropped into the configured reverse micelles drop by drop, and BaCl was obtained after stirring in a water bath at 50°C for 1 h. 2 Microemulsion. In the same way, configure 10ml Er(NO 3 ) 3 , 10ml Yb(NO 3 ) 3 , 10ml Tm(NO 3 ) 3 , 80ml Gd(NO 3 ) 3 , 160ml Na 2 MoO 4 Microemulsion. 37.372mlBaCl 2 Microemulsion, 74.743ml Gd(NO 3 ) 3 microemulsion with 149.486 ml Na 2 MoO 4 After the microemulsion was mixed, 0.42 ml Er(NO 3 ) 3 , 4.2ml Yb (NO 3 ) 3 and 8.4 μl Tm(NO 3 ) 3 The microemulsion was stirred at room temperature for 1.5h to form a white suspension; the precipitate was obtained after ultrasonication, washing, and centrifugation three times with isopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com