Platform used for changing tap hole of converter

A tapping and platform technology, applied in the field of replacing the tapping platform of the converter, can solve the problems of occupying the crane, dangerous operation, affecting the production efficiency of the workshop, etc., and achieve the effect of preventing unstable fixation, ensuring personal safety, and ensuring strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

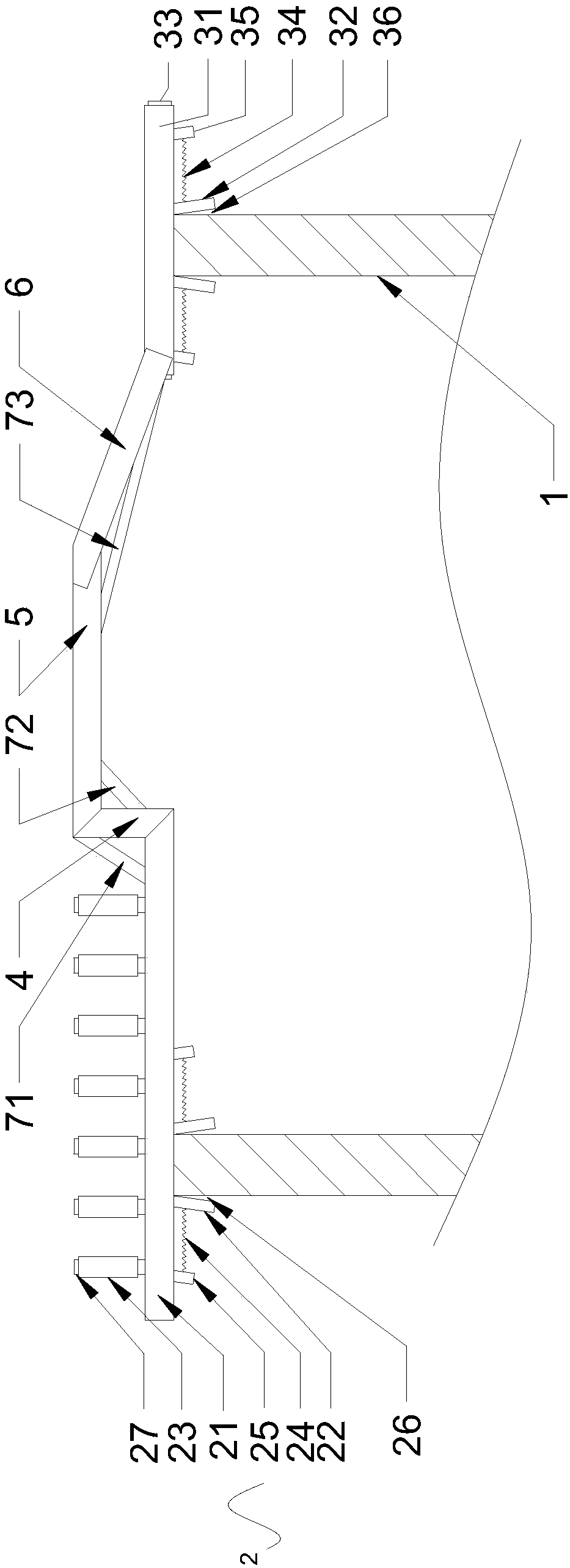

[0035] This embodiment discloses a working platform for replacing the taphole of a converter, see figure 1 , which includes a platform body 2 and a support member, wherein:

[0036] The platform body 2 is set horizontally, and the platform body 2 is provided with a working through hole;

[0037] The supporting member includes an extension plate 4, a connecting plate 5, a brace plate 6 and a positioning plate. The extension plate 4 is arranged vertically. The lower end of the extension plate 4 is fixed on the end of the platform body 2 away from the converter platform 1, and the upper end of the extension plate 4 extends upwards. To the connecting plate 5 and fixedly connected with the connecting plate 5, the connecting plate 5 is arranged horizontally;

[0038] The positioning plate has a first positioning groove 36 with a cross-sectional shape of fan ring, the first positioning groove 36 is in clearance with the upper end of the converter platform 1, and the connecting plate...

Embodiment 2

[0042]On the basis of Embodiment 1, this embodiment also includes a first reinforcement member 71 and a second reinforcement member 72, the first end of the first reinforcement member 71 is connected to the platform body 2, and the opposite end of the first end of the reinforcement member is fixed On the extension board 4 , the first end of the second reinforcement member 72 is fixed to the extension board 4 , and the opposite end of the first end of the second reinforcement member 72 is fixed to the connecting board 5 .

[0043] This embodiment further includes a third reinforcement member 73 , the first end of the third reinforcement member 73 is fixed to the positioning plate, and the opposite end of the first end of the third reinforcement member 73 is fixed to the diagonal bracing plate 6 .

[0044] The extension plate 4, the connecting plate 5, and the slanting plate 6 have a large span, and the three parts and their joints are subject to relatively large shear stress. Th...

Embodiment 3

[0047] On the basis of Embodiment 1 or 2, the bottom of the platform body 2 has a second positioning groove 26 with an annular cross-sectional shape, and the second positioning groove 26 is in clearance fit with the upper end of the converter platform 1 . The bottom of the platform body 2 is provided with a second positioning groove 26 to be stuck on the upper end of the converter platform 1, so that the fixing of the platform body 2 is more stable, preventing the platform body 2 from moving radially along the converter platform 1, and further ensuring the safety of the operators. Personal safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com