540MPa grade hot-rolled pickled steel plate and manufacturing method thereof

A hot-rolled pickling and steel plate technology, which is applied in the field of metal materials, can solve problems such as non-conformity, and achieve the effects of reducing load, improving hardenability, and refining structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

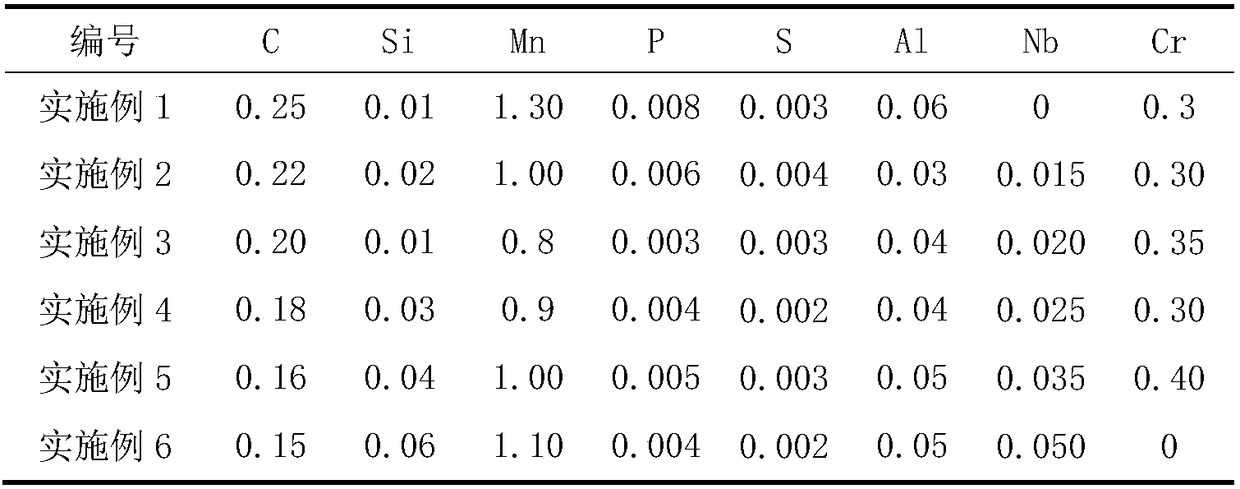

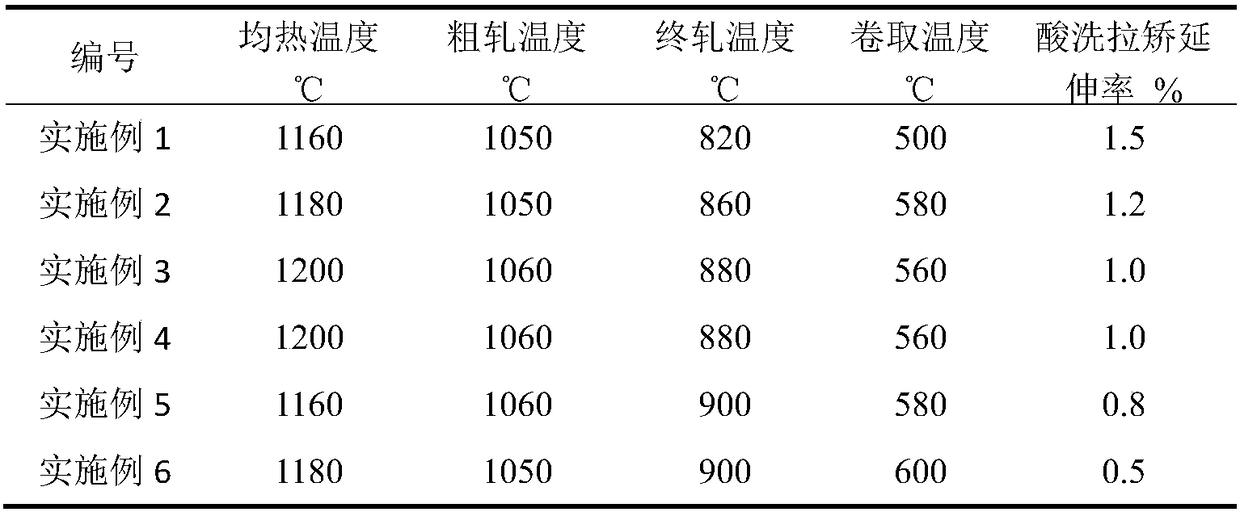

[0025] The present invention is a 540MPa grade hot-rolled pickled steel plate. The chemical composition of the hot-rolled pickled steel plate is calculated by mass percentage: C 0.15%-0.25%, Si 0.01%-0.06%, Mn 0.80%-1.30%, Al 0.01%-0.06%, and 0.015%-0.050% Nb and / or 0.30%-0.40% Cr, and limit P<0.010%, S<0.005%, and the balance is Fe and unavoidable impurities.

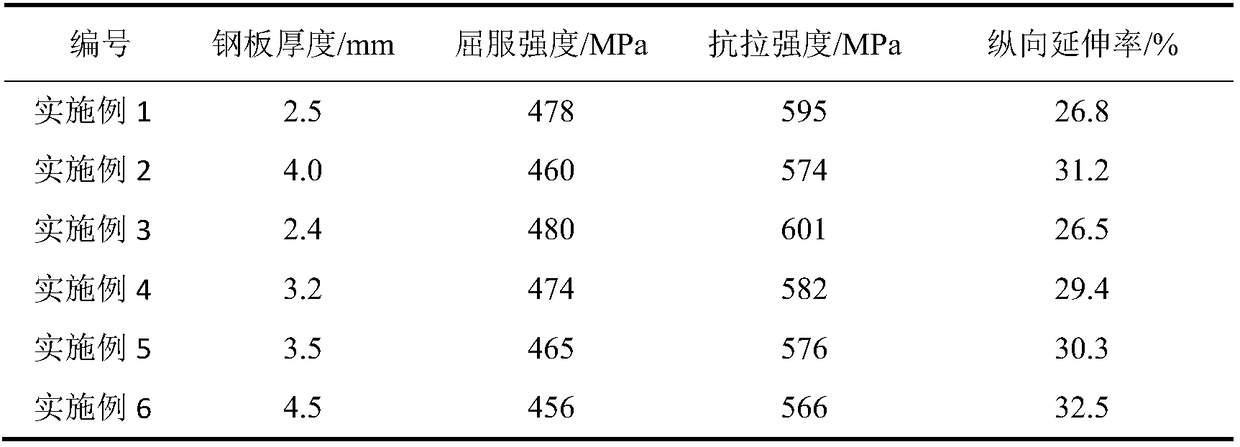

[0026] The final structure of the hot-rolled pickled steel plate is composed of ferrite, pearlite and a small amount of bainite, and its structure composition is 55% to 65% of ferrite, 30% to 40% of pearlite and bainite by volume percentage. Tensile body 5% to 15%, yield strength > 440MPa, tensile strength > 540MPa, longitudinal elongation > 26%.

[0027] The effect of main chemical composition in a kind of 540MPa grade hot-rolled pickled steel plate of the present invention is:

[0028] C: Carbon is the most important solid solution strengthening element in steel, which is the guarantee of steel strength; considering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com