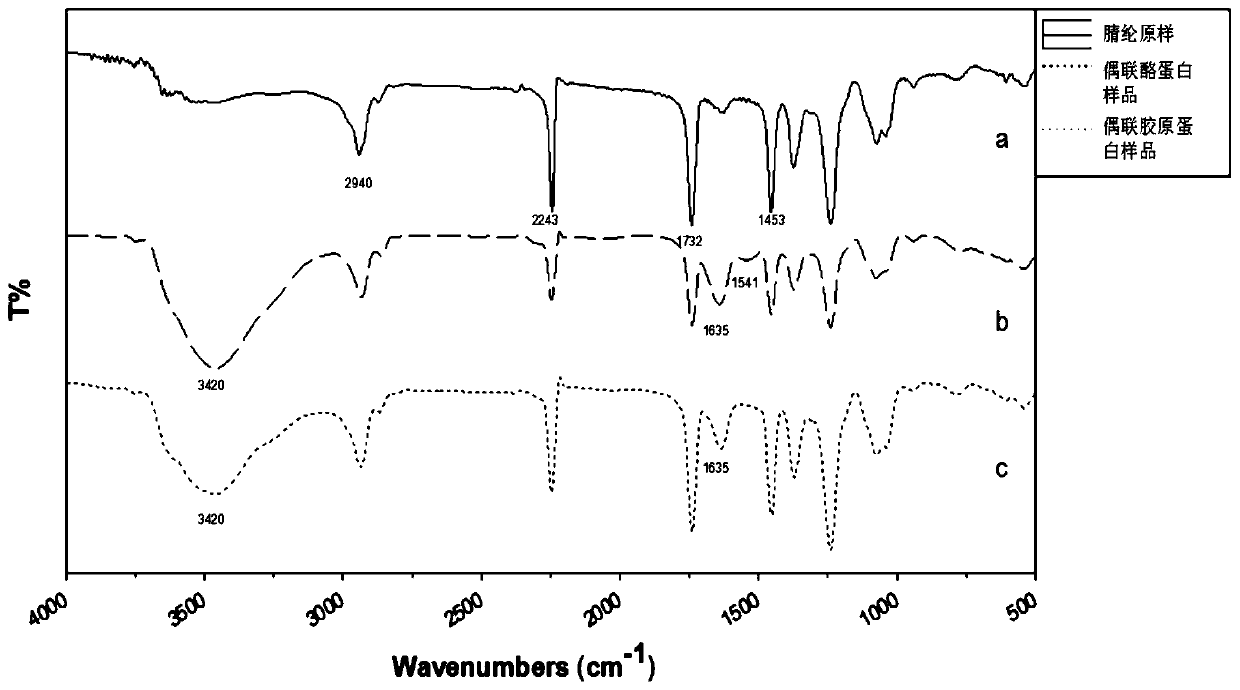

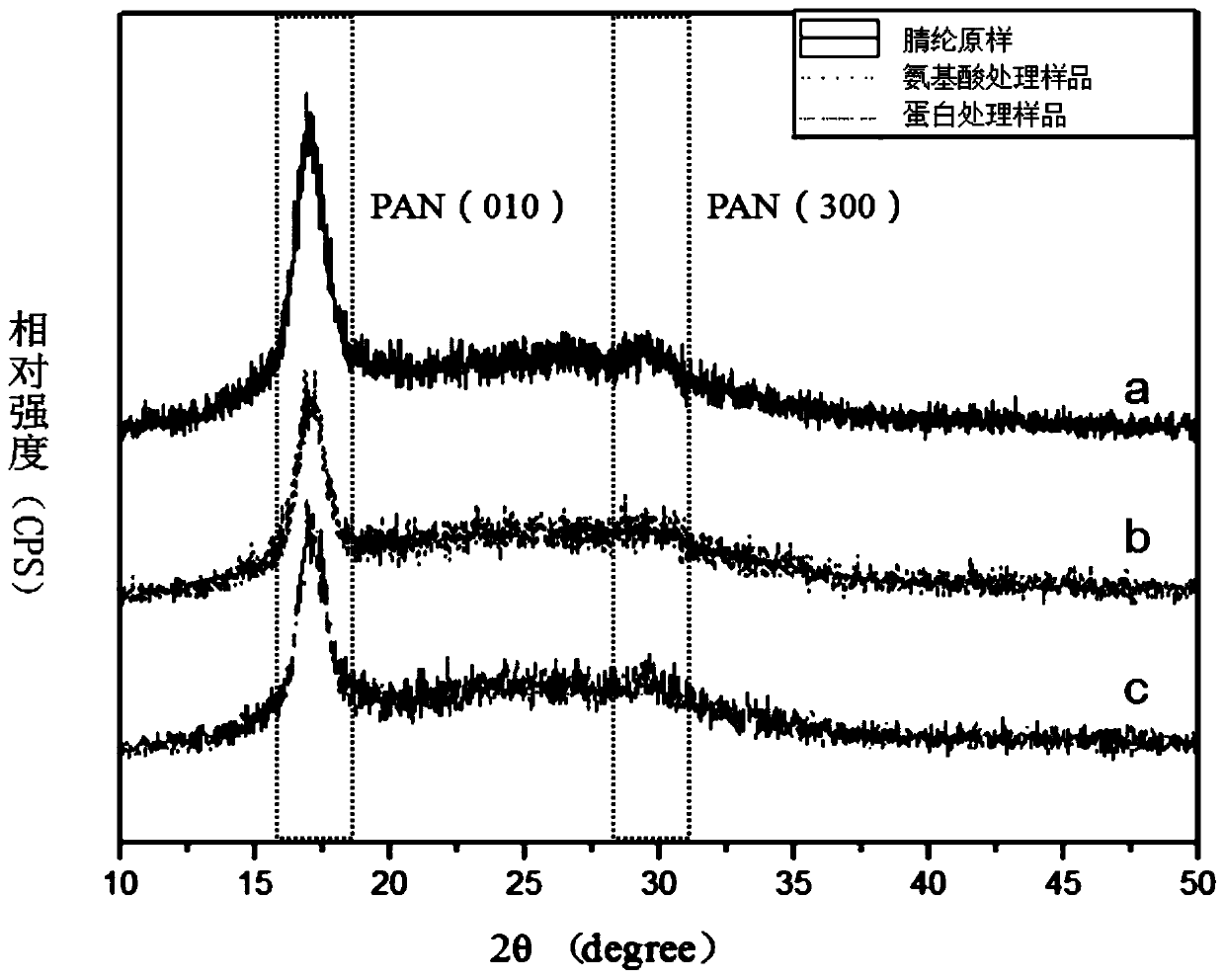

Amino acid covalently coupled protein modified fiber material and preparation method thereof

A protein-modified fiber, covalent coupling technology, applied in the direction of improved hand fiber, fiber treatment, fiber type, etc., to achieve the effect of improving efficiency, good graft fastness, and high graft rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Take 50ml of sodium hydroxide solution with a mass fraction of 5%, put 2g of acrylic fiber into it, use a glass rod to completely impregnate the acrylic fiber, add it to a constant temperature water bath at 80°C and react for 8 minutes, after the hydrolysis reaction is completed, take out the fiber Repeated washing with deionized water until neutral. After drying the fiber, configure 50ml of cysteine hydrochloride solution with a mass fraction of 1% in a beaker, put the fiber into the beaker to fully soak it, put it in a constant temperature water bath with a temperature of 90°C for 1 hour, and take out Repeatedly wash the fibers with deionized water until neutral, put the fibers in an oven to dry; configure 100ml of casein solution with a mass fraction of 2%, put in the fibers and stir until the fibers are fully dispersed and wet, then put them in a constant temperature water bath at 80°C After reacting for 10 minutes, the fibers were taken out and washed repeatedly ...

Embodiment 2

[0047] Take 50ml of sodium hydroxide solution with a mass fraction of 8%, put 2g of acrylic fiber into it, use a glass rod to completely impregnate the acrylic fiber, add it to a constant temperature water bath at 80°C and react for 10min, after the hydrolysis reaction is over, take out the fiber Repeated washing with deionized water until neutral. After the fiber is dried, put 50ml of glycine solution with a mass fraction of 2% in a beaker, put the fiber into the beaker to fully soak it, put it in a constant temperature water bath with a temperature of 90°C for 1 hour, take out the fiber and repeat it with deionized water Wash until neutral, put the fiber in an oven to dry; prepare 100ml of casein solution with a mass fraction of 5%, put it into the fiber and stir until the fiber is fully dispersed and soaked, put it in a constant temperature water bath at 80°C for 10 minutes, and then dry the fiber Take it out and wash it repeatedly to neutrality, put it in a 50°C oven and d...

Embodiment 3

[0049] Take 50ml of sodium hydroxide solution with a mass fraction of 8%, put 2g of acrylic fiber into it, use a glass rod to completely impregnate the acrylic fiber, add it to a constant temperature water bath at 90°C and react for 8min, after the hydrolysis reaction is over, take out the fiber Repeated washing with deionized water until neutral. After drying the fiber, configure 50ml of cysteine hydrochloride solution with a mass fraction of 1% in a beaker, put the fiber into the beaker to fully soak it, put it in a constant temperature water bath with a temperature of 90°C for 1 hour, and take out Wash the fiber repeatedly with deionized water until it is neutral, put the fiber in an oven to dry; configure 200ml of collagen solution with a mass fraction of 5%, put it into the fiber and stir until the fiber is fully dispersed and soaked, then put it in a constant temperature water bath at 80°C After reacting for 10 minutes, the fibers were taken out and washed repeatedly u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com