Individual pitch-changing control optimization method for large-scale wind generating set

A technology of wind turbines and independent pitch adjustment, which is applied to the control of wind turbines, wind turbines, and engine control parameters, etc. Balance the load, reduce the peak value of unbalanced load, and improve the life of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

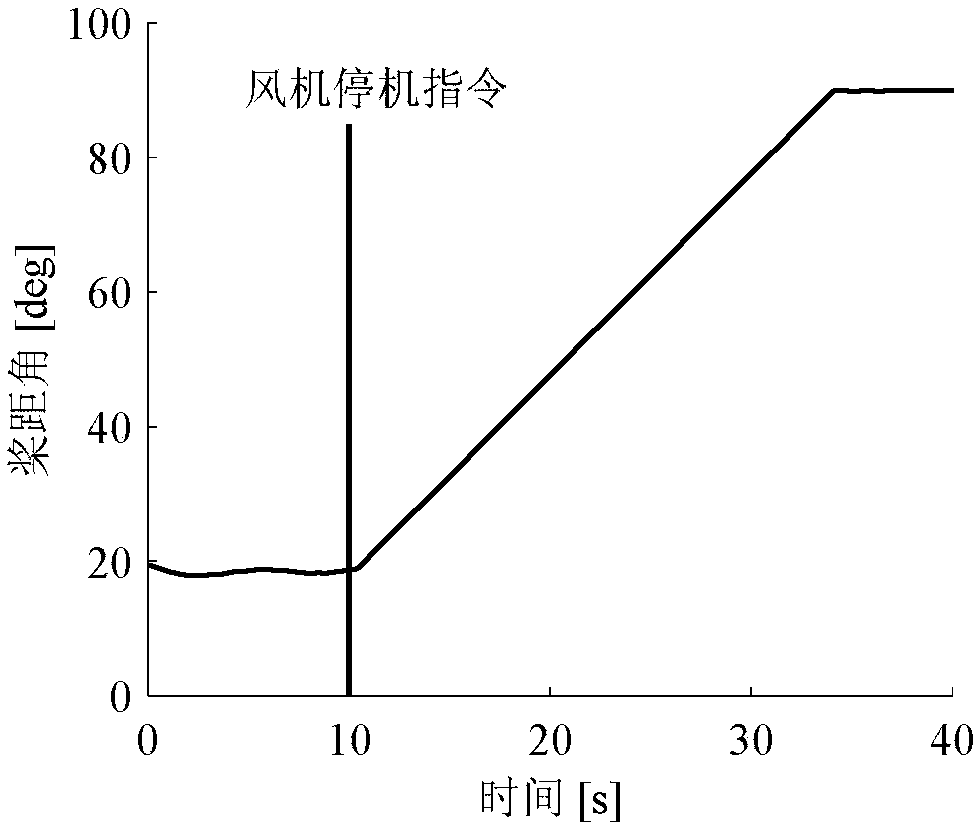

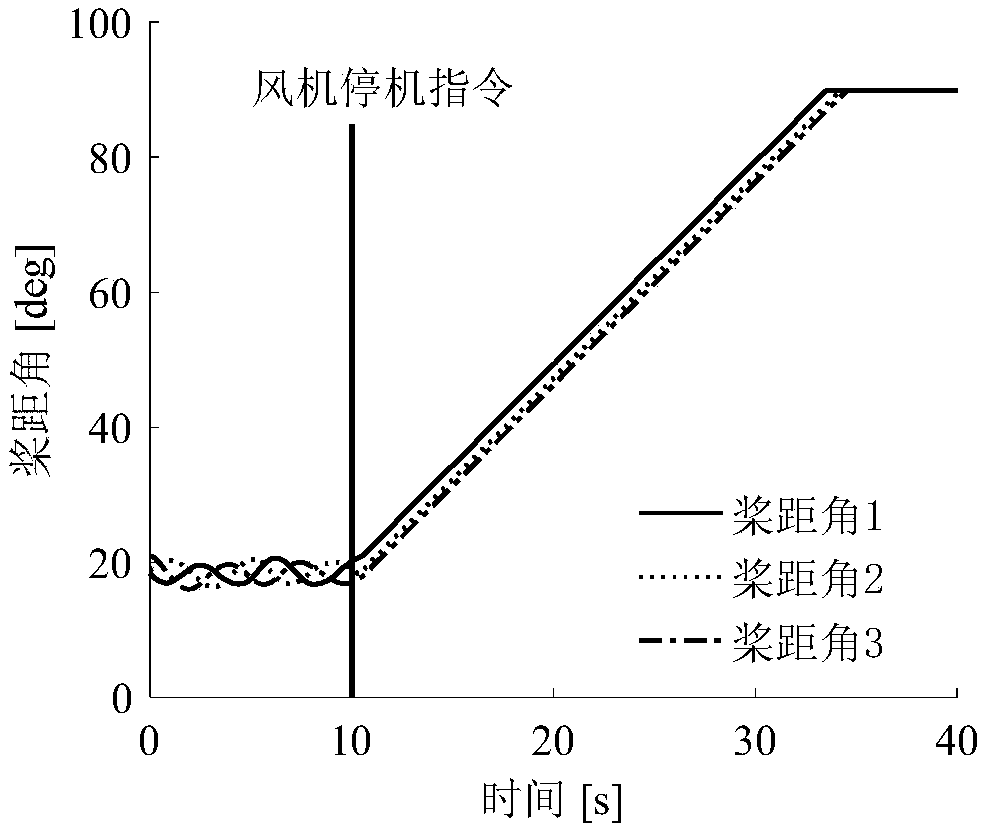

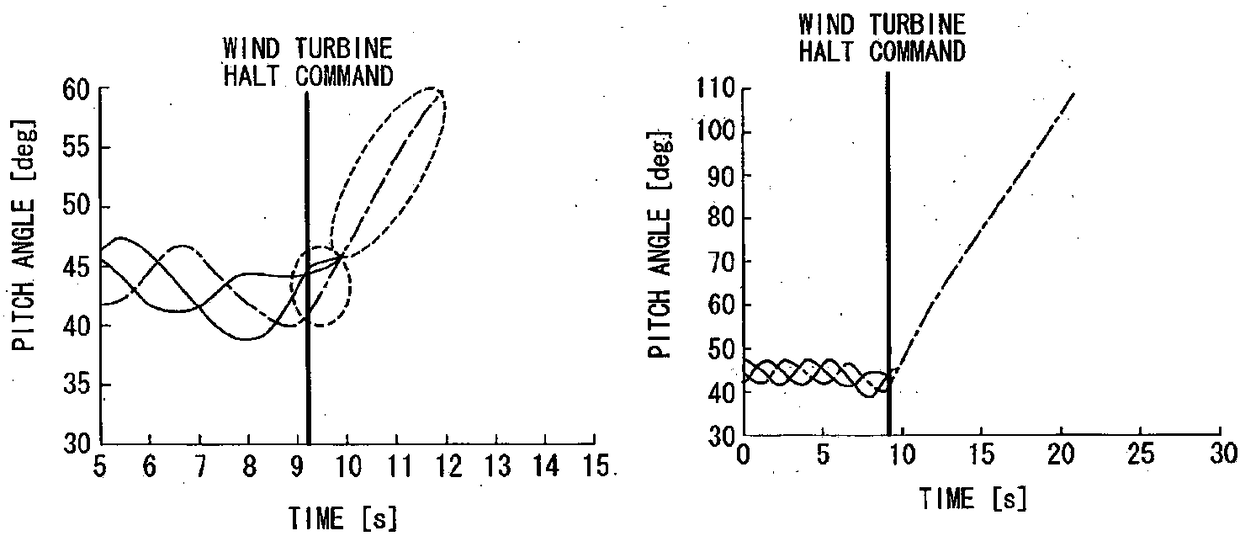

[0037] Such as Figure 5 As shown, the independent pitch control loop of a large wind turbine can be decoupled into a cooperative pitch control loop and a deviation pitch control loop: through the cooperative pitch control loop, the traditional variable speed and pitch control function of the wind turbine is realized, that is, through the cooperative pitch control loop When the wind speed is lower than the rated wind speed, the blades are always controlled to be near the optimal pitch angle to achieve maximum energy capture; when the wind speed is higher than the rated wind speed, the output power of the generator is kept stable through the coordinated pitch control; The propeller control ring reduces the unbalanced load on the impeller, thereby reducing the fatigue load of the key components of the wind turbine. The independent pitch control loop of large wind turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com