Athermalization high-resolution prime lens

A fixed-focus lens, high-resolution technology, used in optical components, optics, instruments, etc., can solve problems such as low pixels, complex structure, and inability to work normally, to control distortion and chromatic aberration, overcome low image quality, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

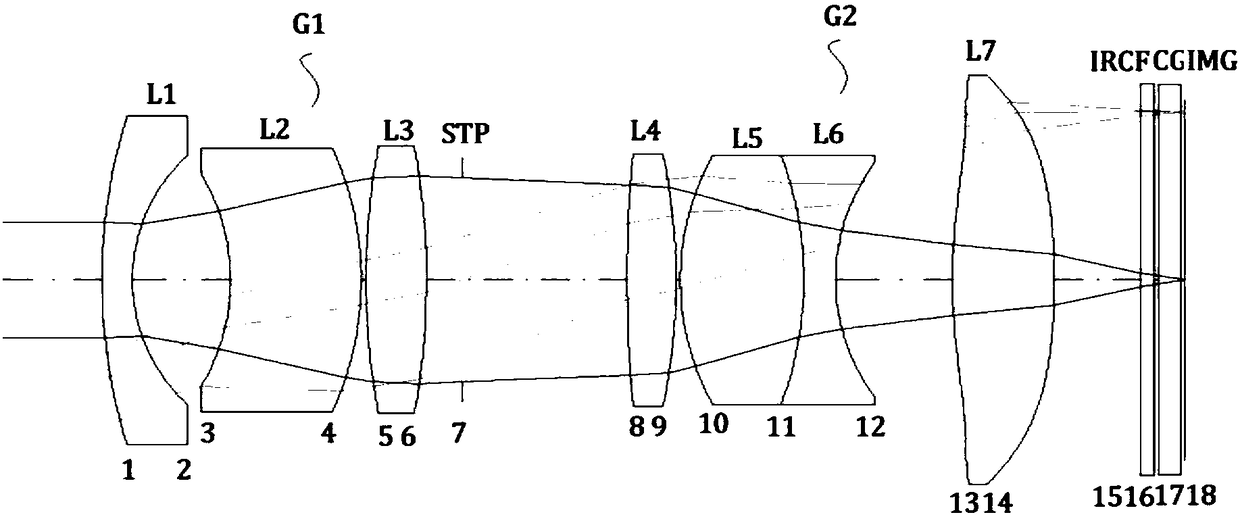

[0038] Such as figure 1 As shown, the present embodiment includes in sequence from the object side to the image side: a front group lens G1 with negative refractive power, a stop STP, a rear group lens G2 with positive refractive power, and an imaging surface IMG.

[0039] The front group lens G1 includes in sequence: a first lens group L1, a second lens L2 with negative refractive power, and a third lens L3 with positive refractive power.

[0040] The first lens group L1 is a first lens with negative refractive power.

[0041] The rear lens group G2 includes in turn: a fourth lens L4 with positive power, a fifth lens L5 with positive power, a sixth lens L6 with negative power, and a seventh lens L7 with positive power .

[0042] The first lens group L1, the second lens L2 and the sixth lens L6 are concave lenses; the third to fifth lenses L3-L5 and the seventh lens L7 are convex lenses.

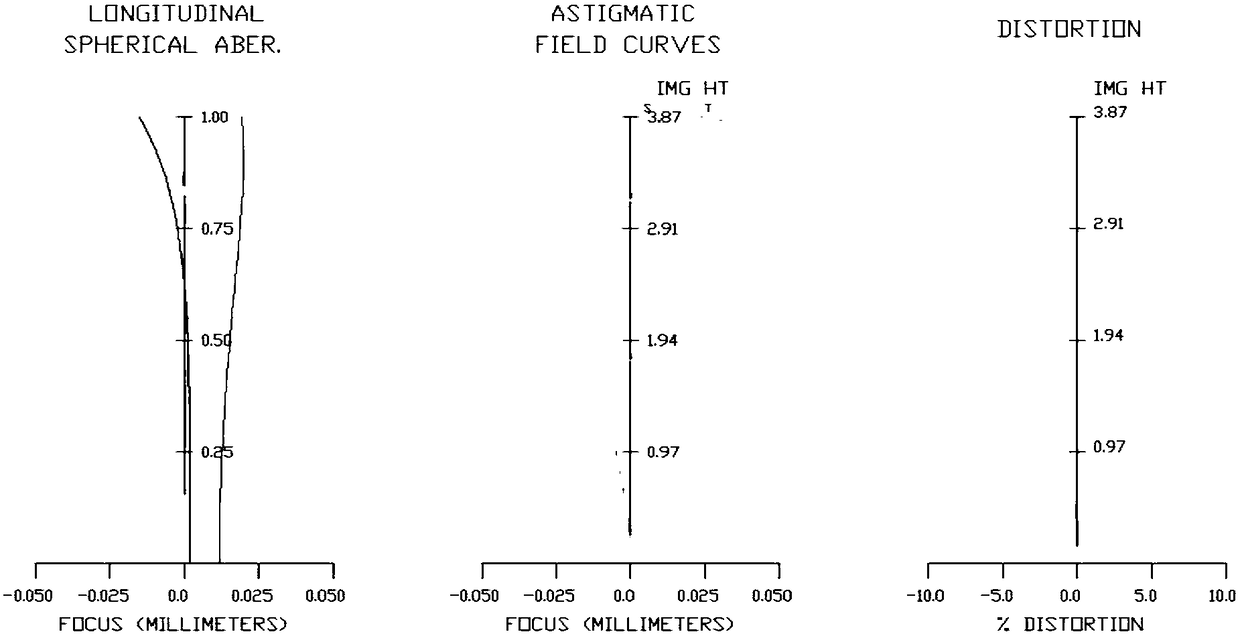

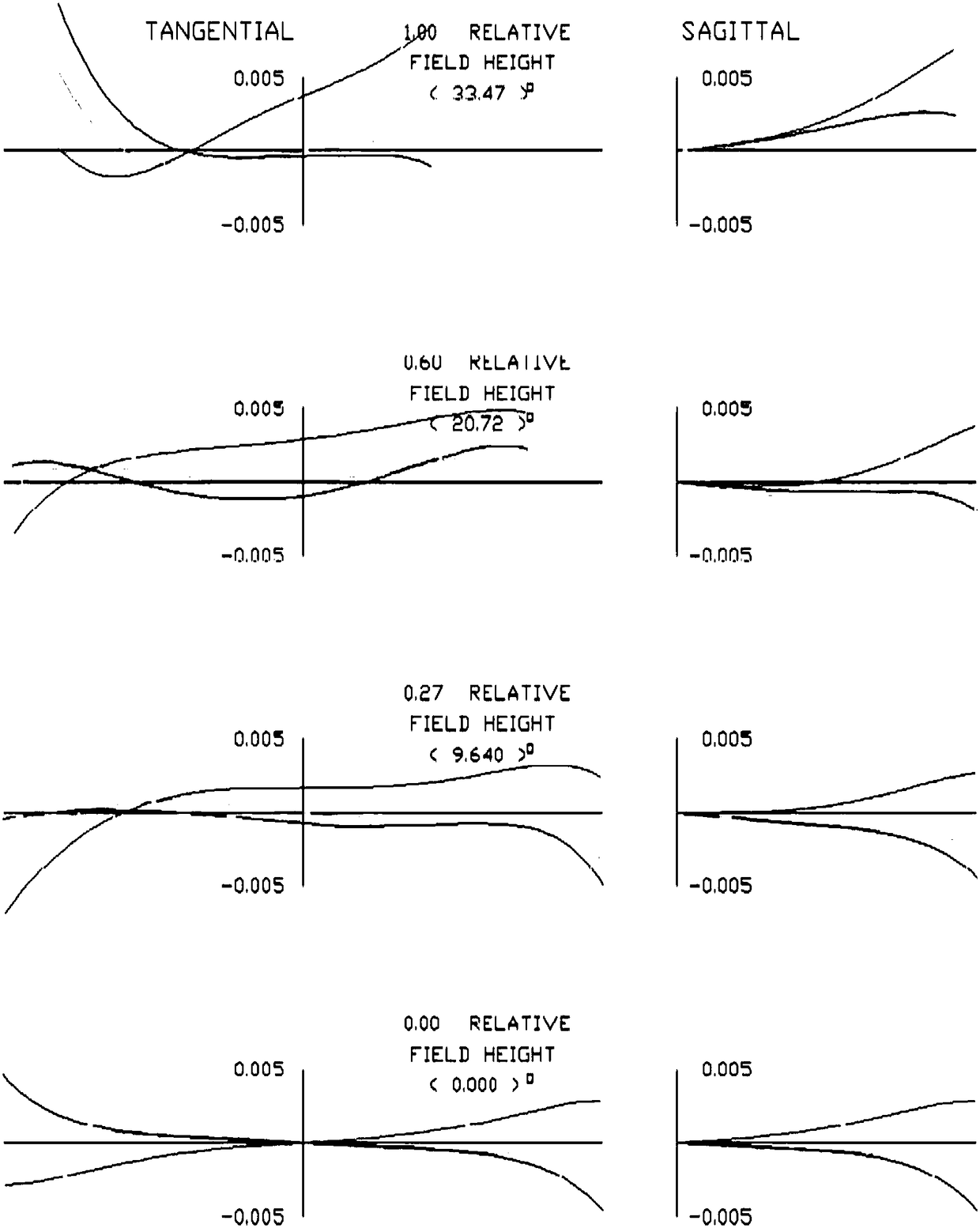

[0043] Various numerical data related to this embodiment are shown below.

[0044] F...

Embodiment 2

[0056] Such as Figure 4 As shown, compared with Embodiment 1, the rear group lens G2 of this embodiment sequentially includes: the fourth lens L4 with positive refractive power, the fifth lens L5 with positive refractive power, and the sixth lens with negative refractive power L6 and a seventh lens L7 with positive power.

[0057] The fifth lens L5 is a cemented lens, including a first front lens L51 and a first rear lens L52.

[0058] Various numerical data related to this embodiment are shown below.

[0059] Focal length F=6mm; relative aperture FNO=2.1mm; field of view FOV=66.5°.

[0060] Table 3 Lens structure parameters of this embodiment

[0061]

[0062]

[0063] The fifth lens L5 in this embodiment is a doublet lens, and the second surface of the first front lens L51 is the first surface of the first rear lens L52.

[0064] Table 4 is the lens aspheric coefficient of the present embodiment

[0065] Surface serial number

K

A4

B6

C8

D...

Embodiment 3

[0069] Such as Figure 7 As shown, compared with Embodiment 2, the front group lens G1 of this embodiment sequentially includes: a first lens group L1, a second lens L2 with negative refractive power, and a third lens L3 with positive refractive power.

[0070] The first lens group L1 includes two lenses, which are the second front lens L11 with positive refractive power and the second rear lens L12 with negative refractive power.

[0071] Various numerical data related to this embodiment are shown below.

[0072] Focal length F=5.8mm; relative aperture FNO=1.8mm; field of view FOV=66.5°.

[0073] Table 5 Lens structure parameters of this embodiment

[0074]

[0075]

[0076] The fifth lens L5 in this embodiment is a doublet lens, and the second surface of the first front lens L51 is the first surface of the first rear lens L52.

[0077] Table 6 is the lens aspheric coefficient of the present embodiment

[0078] Surface serial number

K

A4

B6

C8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com